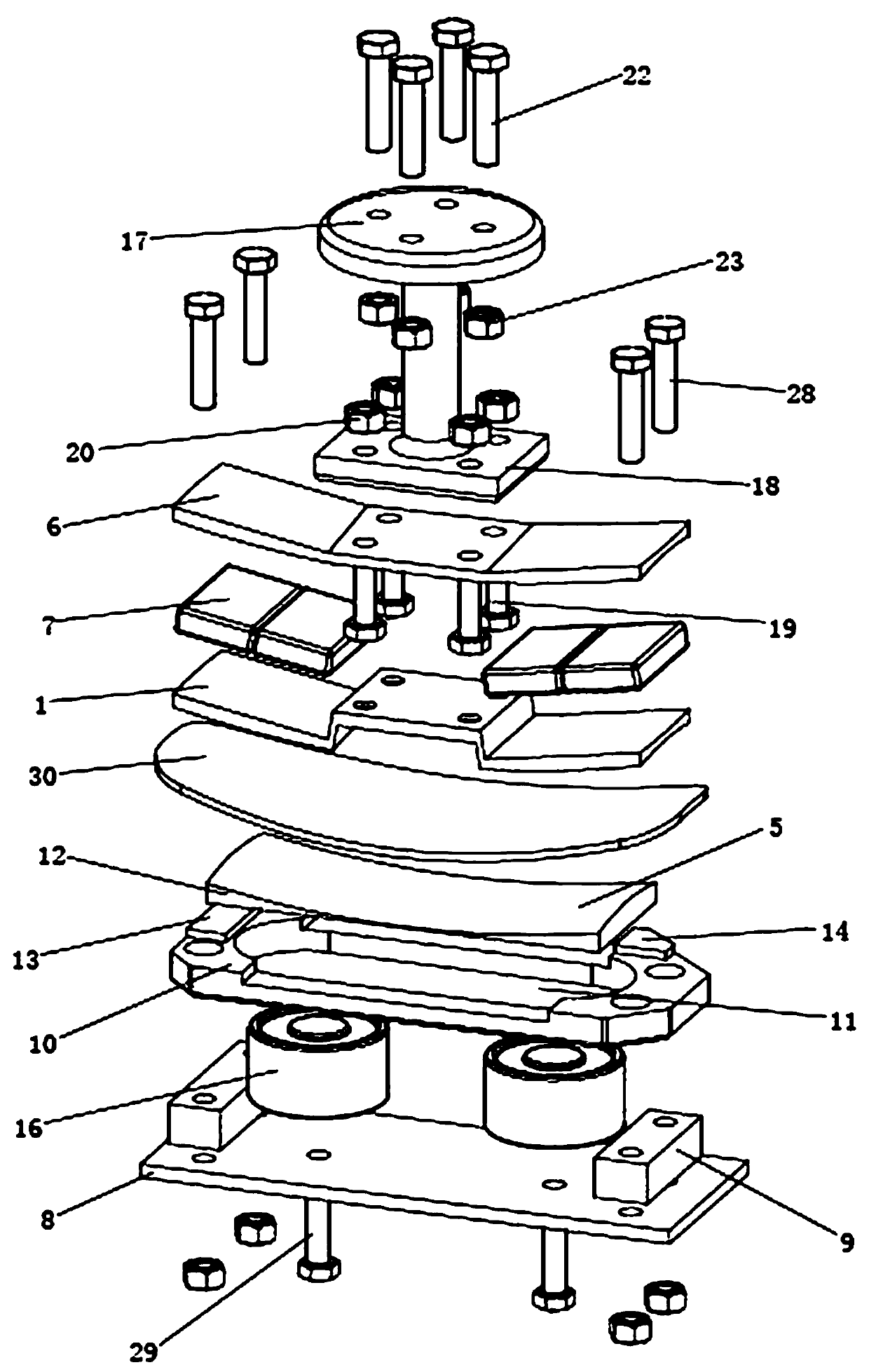

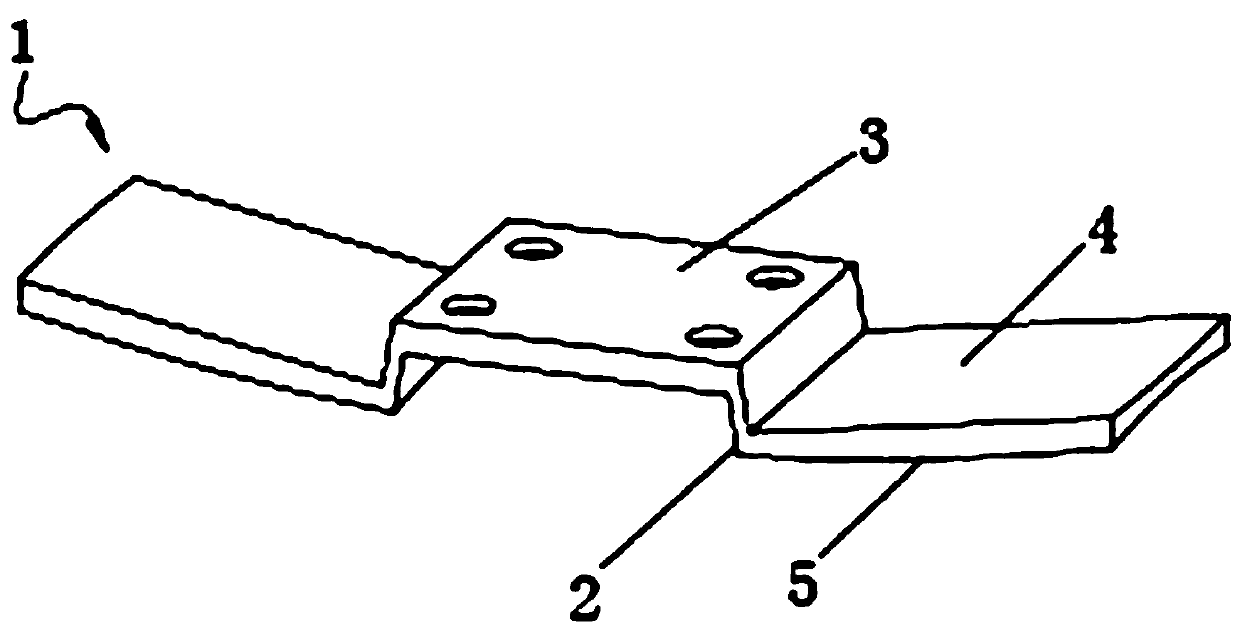

Small-sized thin-wall non-magnetic workpiece positioning and clamping device suitable for automatic production line

An automatic production line, positioning and clamping technology, applied in positioning devices, metal processing machinery parts, clamping, etc., can solve problems such as poor positioning accuracy, health hazards of workers, and high risk factor of work, so as to achieve low machining interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

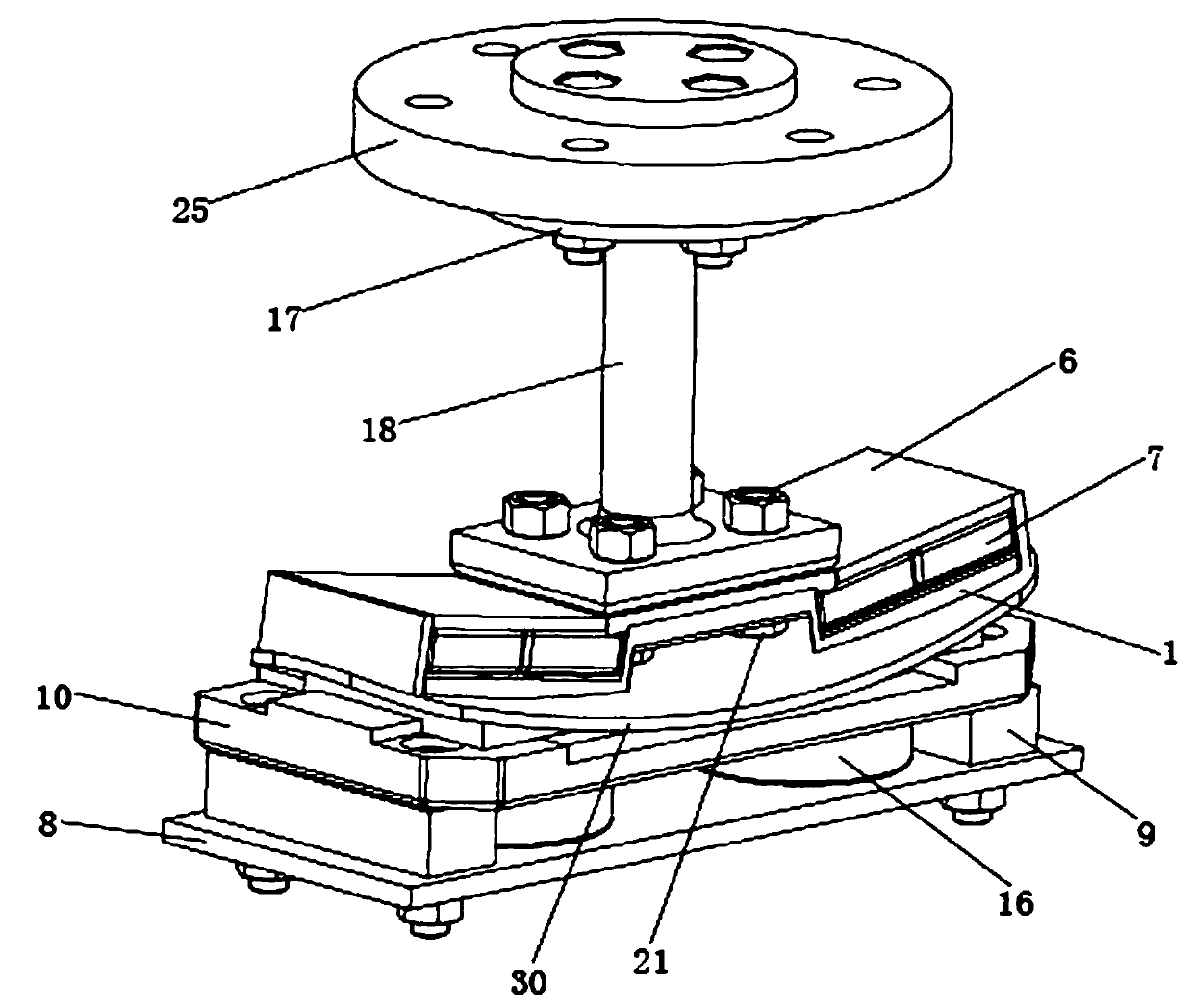

[0071] In order to increase the frictional force of the second magnetically conductive clamping plate 12 on the workpiece 30 when the workpiece 30 is processed, and improve the stability of the clamping device; the second embodiment of the present invention, such as Figure 5 As shown, a workpiece positioning and clamping device in this embodiment, the lower die set in its structure also includes an anti-slip pad 31 with a relatively large friction coefficient with respect to the material of the workpiece 30, and the anti-slip pad 31 is closely attached to On the second workpiece clamping curved surface 15 of the second magnetic conduction clamping plate 12, and both are fixed. In this embodiment, the anti-slip gasket 31 is made of silica gel with a high friction coefficient.

[0072] In order to make the lower mold group can rotate freely in a certain angle range in the vertical direction, the workpiece 30 above can be placed on the positioning table 10 through various geomet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com