Flushing unit for tool change mechanism of processing machine and quick tool change method

A technology of tool changing mechanism and processing machine, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc. It can solve the problems of affecting the injection pressure, interfering with normal tool changing, polluting the tool magazine, etc., and achieves the effect of high efficiency and cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

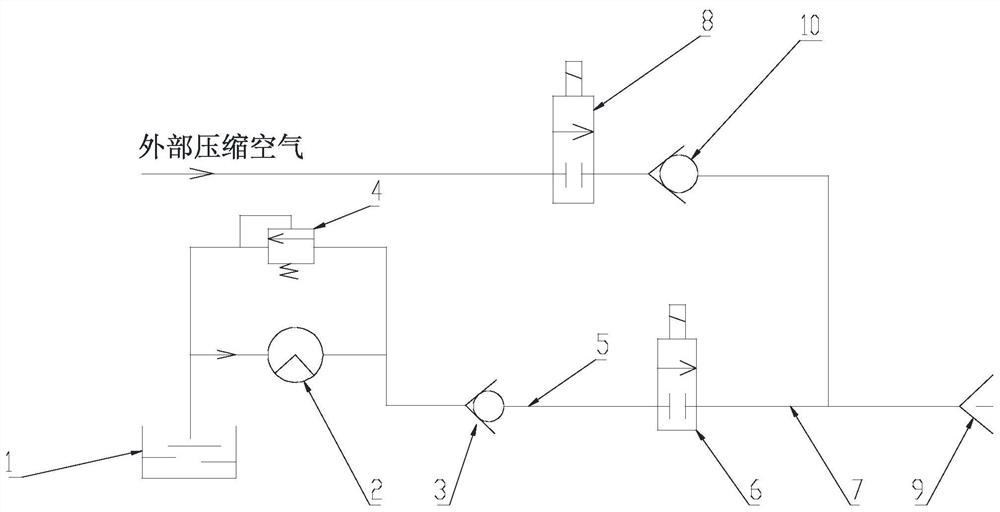

[0036]An embodiment of the present invention provides a flushing unit for a tool change mechanism of a processing machine, such as figure 1 As shown, it includes: a water pump 2, a first one-way valve 3, a second one-way valve 10, a first controllable valve 6, a second controllable valve 8 and a spray nozzle 9, wherein the first one-way valve 3 uses a paddle The one-way valve and the paddle-type one-way valve have strict restrictions on the installation method, and are suitable for vertical installation at the outlet of the water pump or horizontal installation under partial conditions. The first controllable valve 6 adopts an angle seat valve, and the second controllable valve 8 adopts a two-way electric control valve. In actual production applications, a liquid storage tank 1 is also required. The flushing liquid is stored in the liquid storage tank 1, and the flushing liquid can be As a cooling liquid during processing, it can also be used as a cleaning liquid for processin...

Embodiment 2

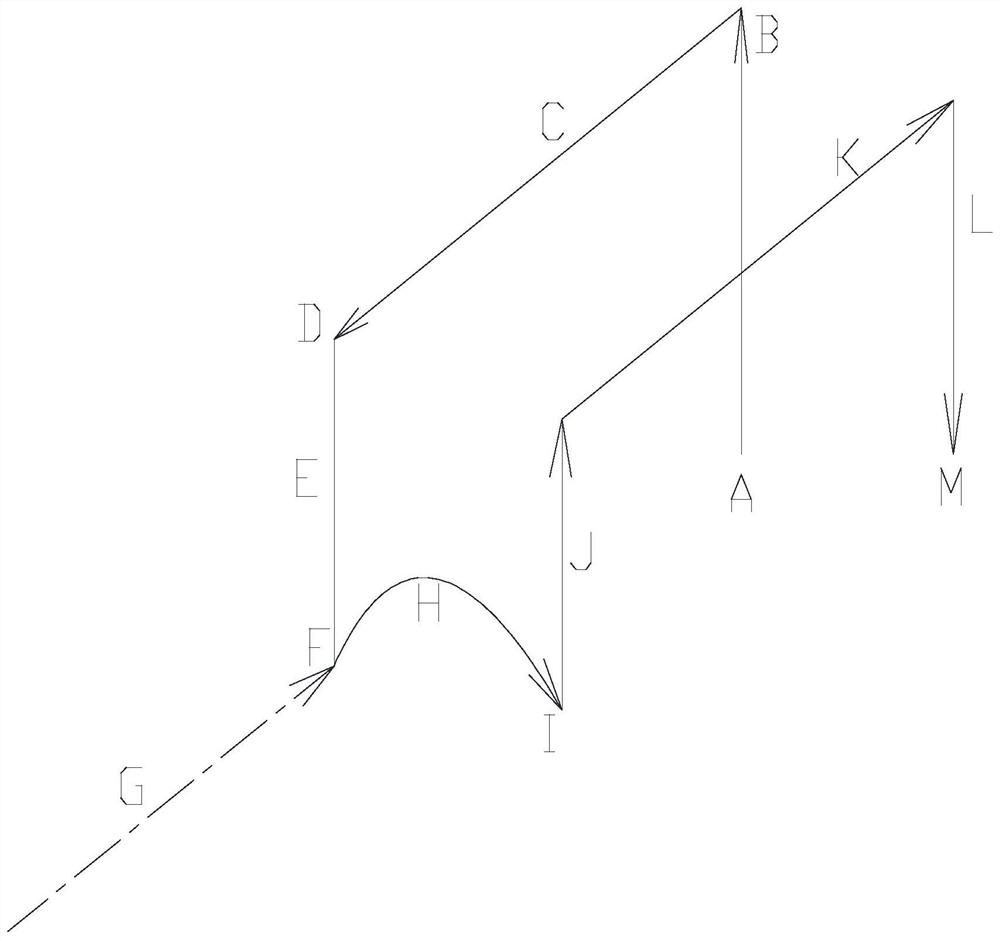

[0043] This embodiment provides a quick tool change method for a processing machine, which can be realized based on the flushing unit in the above-mentioned embodiment 1, and other key components in the processing machine can be known from the prior art, such as the processing spindle The drive and structure, the drive and structure of the tool magazine, so no more details.

[0044] The quick tool change method for a processing machine provided in this embodiment includes 4 key steps.

[0045] 1. Preparation steps for tool change.

[0046] In this step, the previous processing procedure has been completed and the cutter head needs to be replaced to process the workpiece in the next procedure. In the previous processing method, the processing spindle can be controlled to stop rotating, but in this step of the present invention, the processing spindle will still be controlled to continue to rotate after the processing is completed, but the control water pump is closed, the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com