Pose identifying and grabbing device and method based on binocular vision

A binocular vision, pose technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problem of not considering the initial and final attitude of the product, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

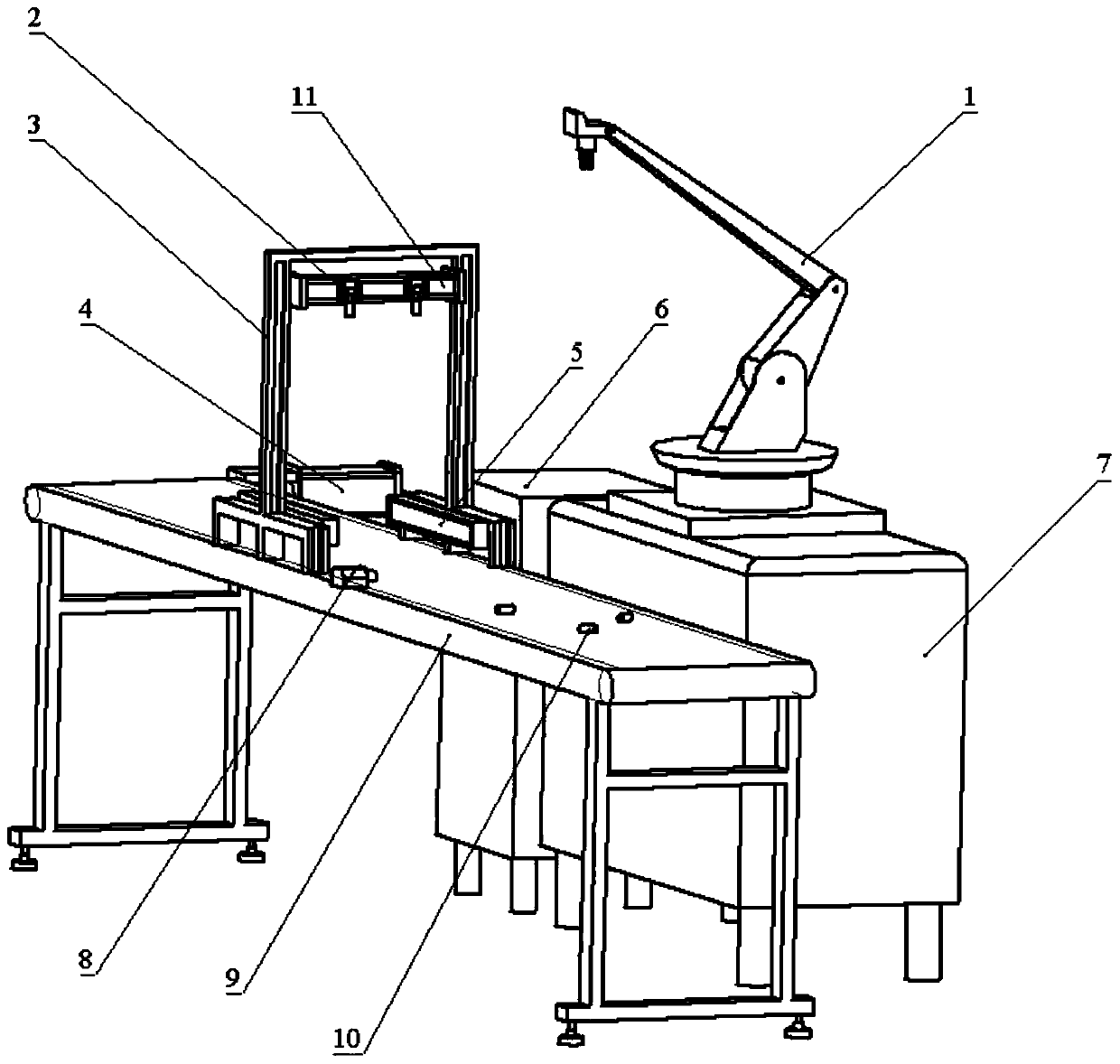

[0055] Specific implementation methods (such as image 3 and Figure 4 shown):

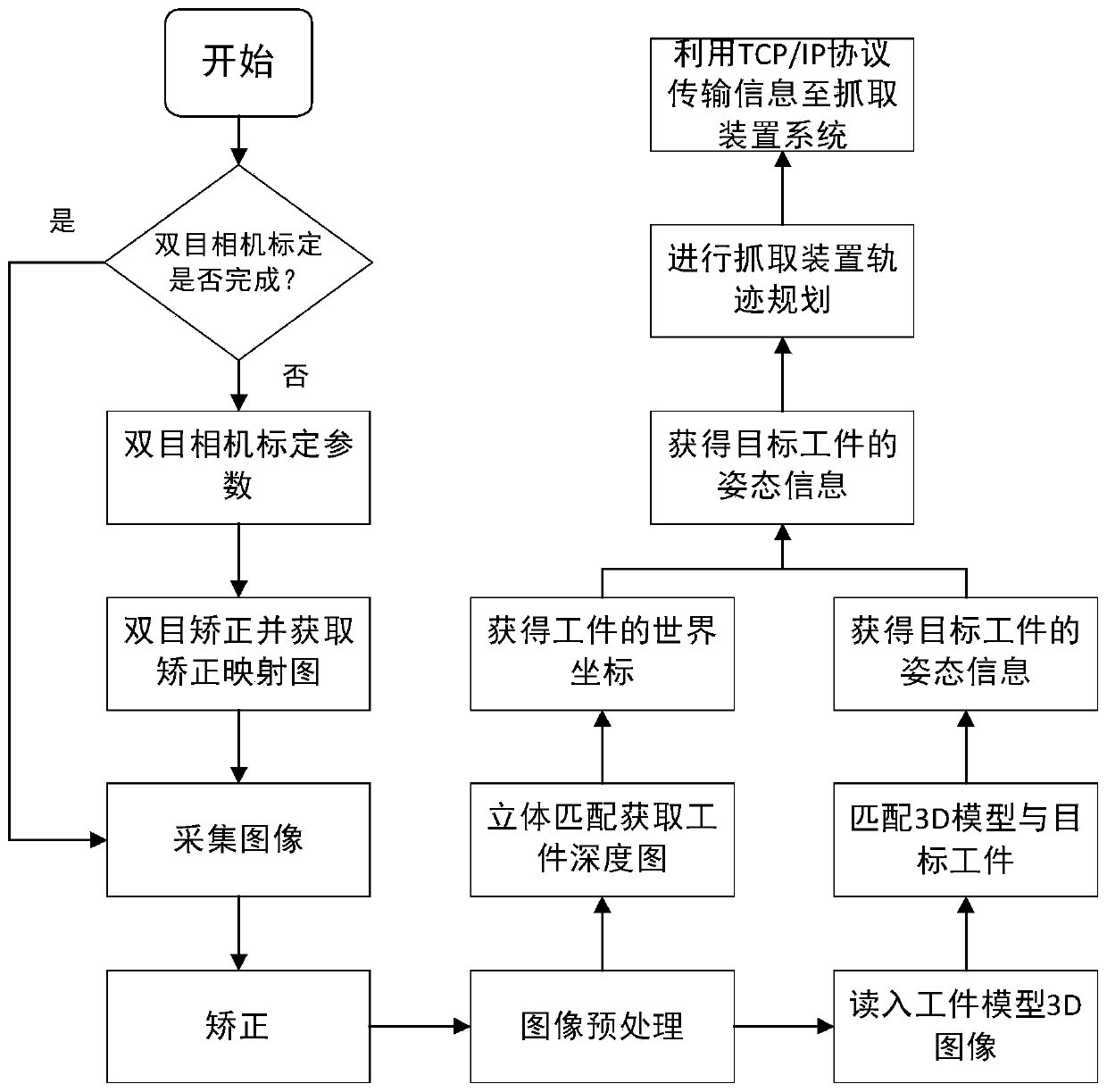

[0056] Such as Figure 5 The gray coordinate system (X, Y, Z) shown is the camera coordinate system, and the two black two-dimensional coordinate systems are the pixel coordinate system (x, y) of the left and right cameras respectively. The pixel coordinate system of the left camera is located at At (0,0,0) of the camera coordinate system, the pixel coordinate system of the right camera is located at (Tx,0,0) of the camera coordinate system. (X, Y, Z) in the figure is a point in the camera coordinate system.

[0057] Such as Figure 6 Shown is the workpiece coordinate system, which is established based on the center of the bottom circle of the target workpiece.

[0058] Such as Figure 7 Shown is the coordinate system of the manipulator, established with the origin of the center of the manipulator base.

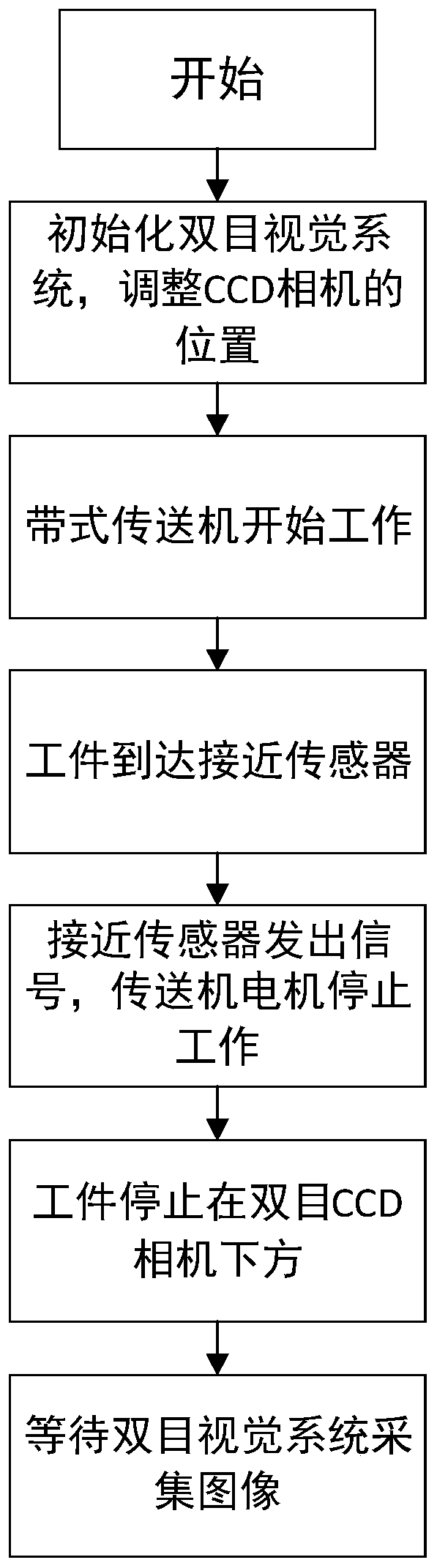

[0059] Step 1: by adjusting the height of the industrial camera 2, the shooting angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com