Forward wheel drive passenger vehicle tire burst control method

A control method and technology for passenger cars, applied to safety devices of power plant control mechanisms, tractors, motor vehicles, etc. Sudden changes in speed, guaranteed driving safety, and automatic deviation correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

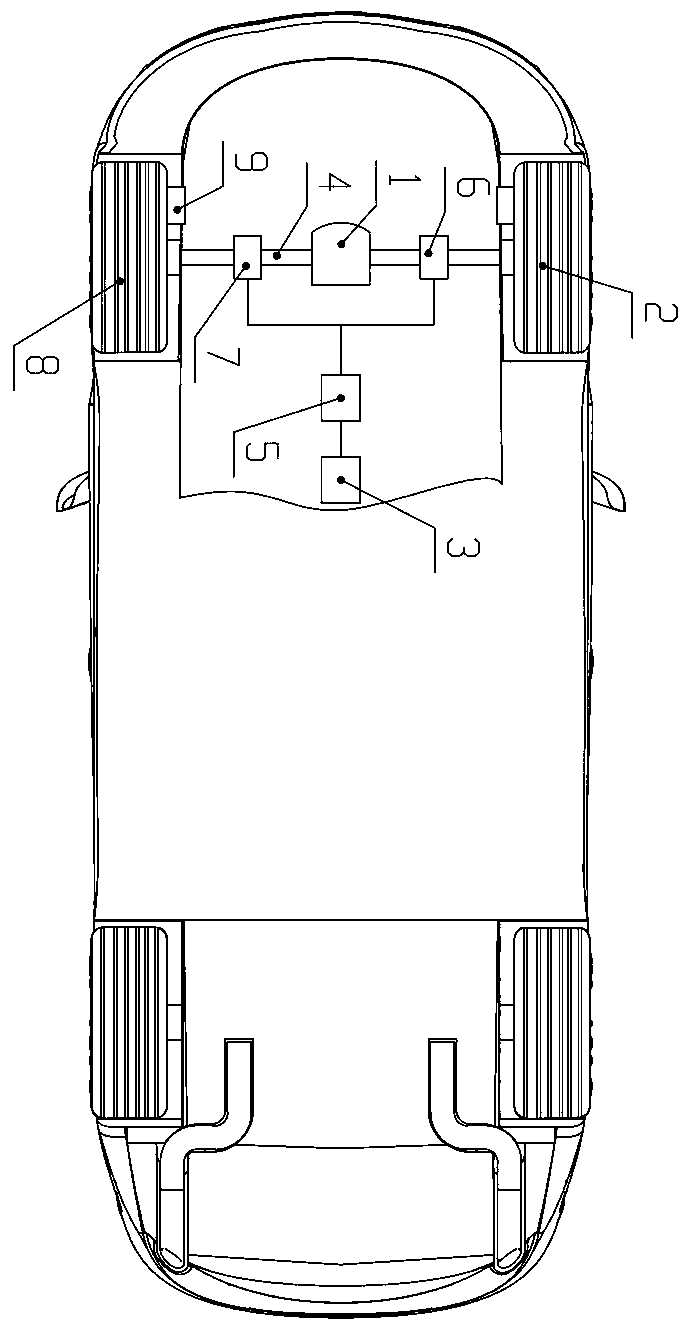

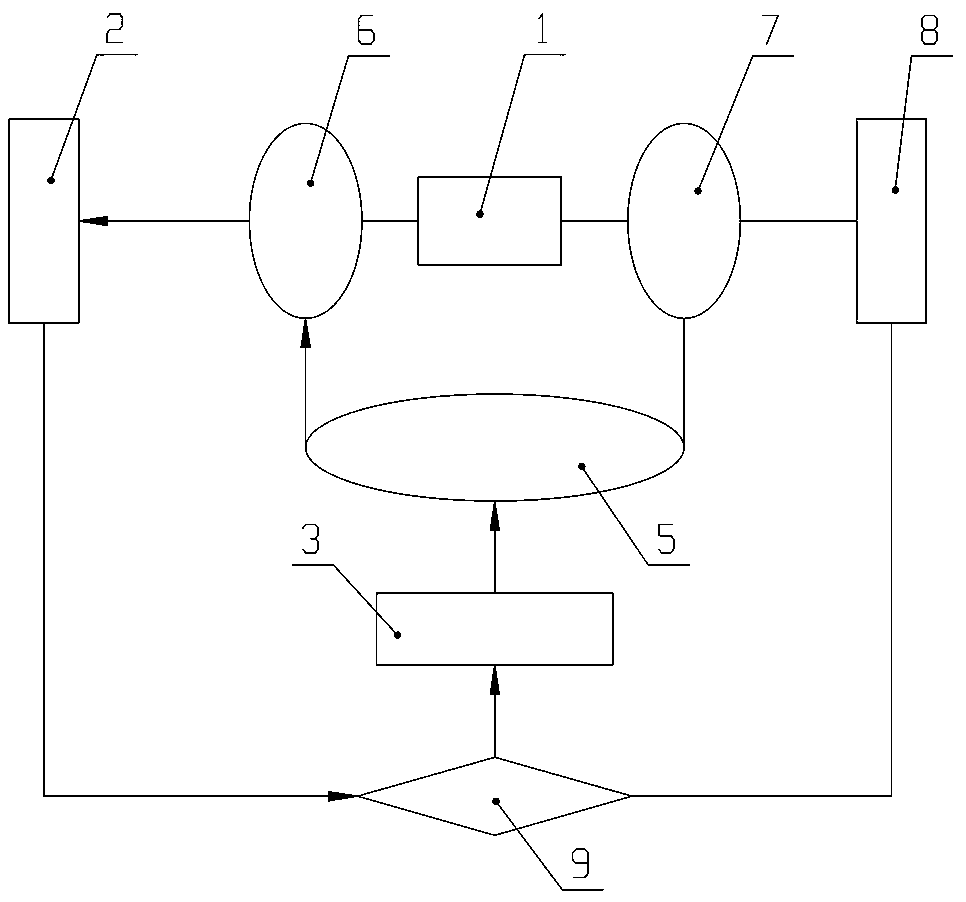

[0027] Such as Figure 1 ~ Figure 3 As shown, a tire blowout control method for a front-drive passenger car. When the vehicle detects that a tire blowout has occurred in the driving wheel, the torque and speed output by the vehicle's own differential 1 are used to accelerate the speed of the blown driving wheel, so that The driving speed of the blown tire driving wheel is consistent with that of the normal driving wheel, and the driving force is balanced.

[0028] Said using the torque output by the vehicle's own differential 1 and the rotational speed to accelerate the rotational speed of the punctured wheel includes: when the detection result is that the left driving wheel 2 is punctured, on the one hand, the kinetic energy of the left driving wheel 2 punctured moment continues to It forms traction force by itself, on the other hand, the control unit 3 of described vehicle immediately cuts off the power connection between the left driving wheel 2 and the differential gear 1 ...

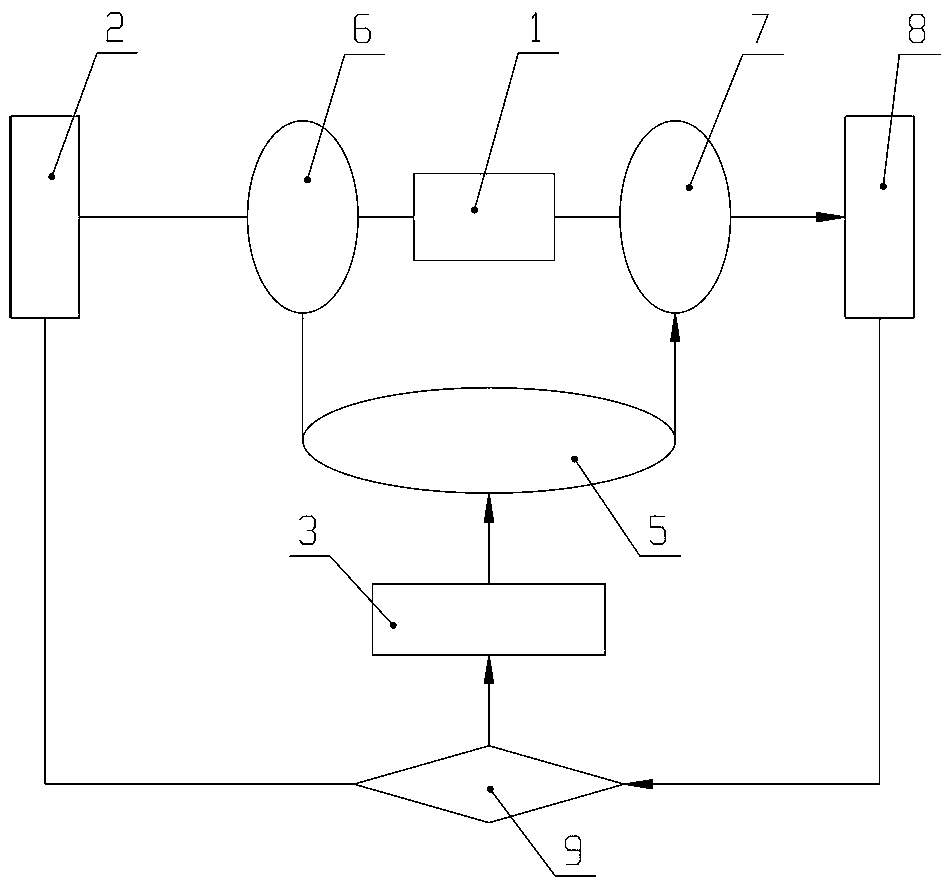

Embodiment 2

[0035] The difference between the second embodiment and the first embodiment is that when the vehicle detects that the tire of the driving wheel is blown out, the normal driving wheel is decelerated by using the torque and the rotational speed output by the differential 1 of the vehicle itself; the normal driving wheel is decelerated The principle is the same as the principle of accelerating the tire blown drive wheel, so no more details here.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap