Crack-resistant concrete structure and construction method thereof

A technology of concrete structure and concrete layer, applied in the direction of basic structure engineering, structural elements, earthwork drilling and mining, etc., can solve the problems of pedestrian injury, difficult repair construction, safety threat, etc., and reduce the possibility of injury to staff , Inhibit the further expansion of cracks and reduce the effect of potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

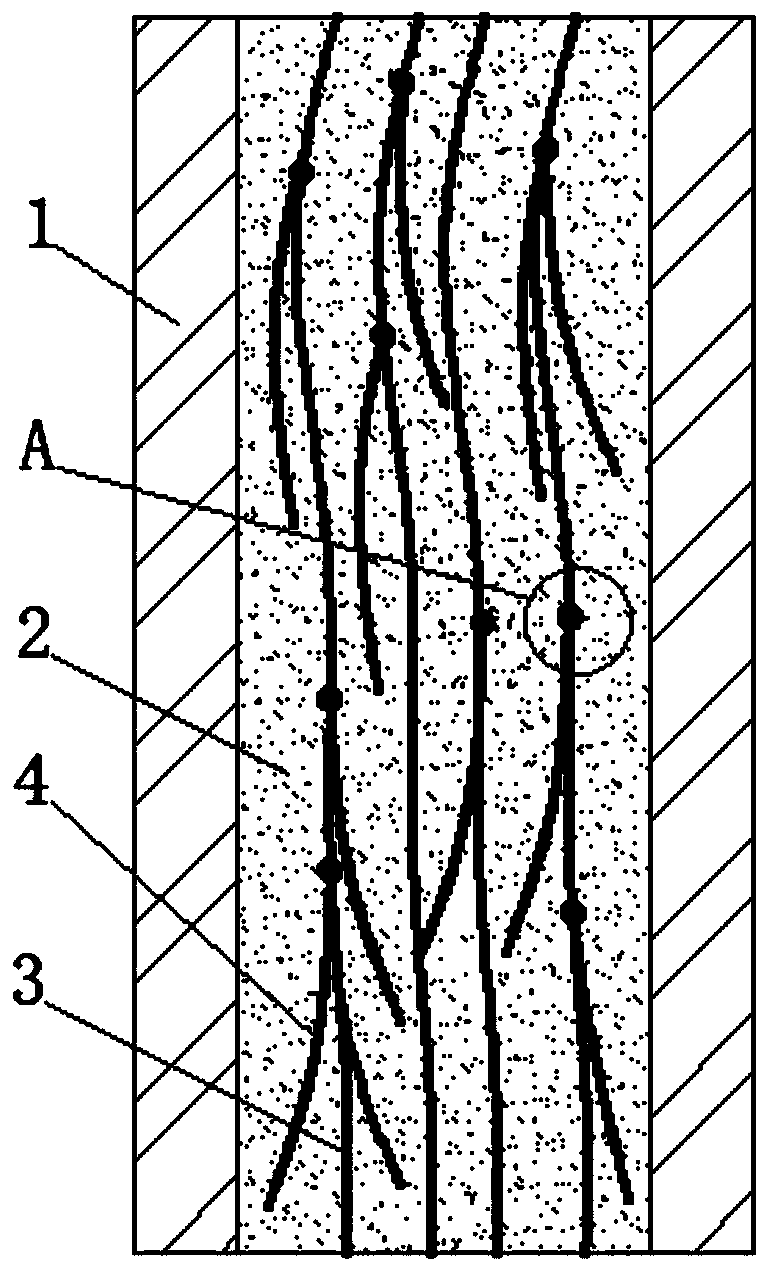

[0044] see figure 1 , a crack-resistant concrete structure, including a prefabricated formwork 1, a concrete layer 2 is filled in the prefabricated formwork 1, and a plurality of randomly distributed multi-branched wires are embedded in the concrete layer 2, and the multi-branched wires include trunk wires 3 and multi-branched wires. A split wire 4, the multi-branched wires are longitudinally distributed in the concrete layer 2, so that the concrete exhibits tensile properties in the longitudinal direction, and at the same time, after accidental cracking, in the longitudinal direction, under the action of the multi-branched wires, it can show mutual involvement , not easy to crack further.

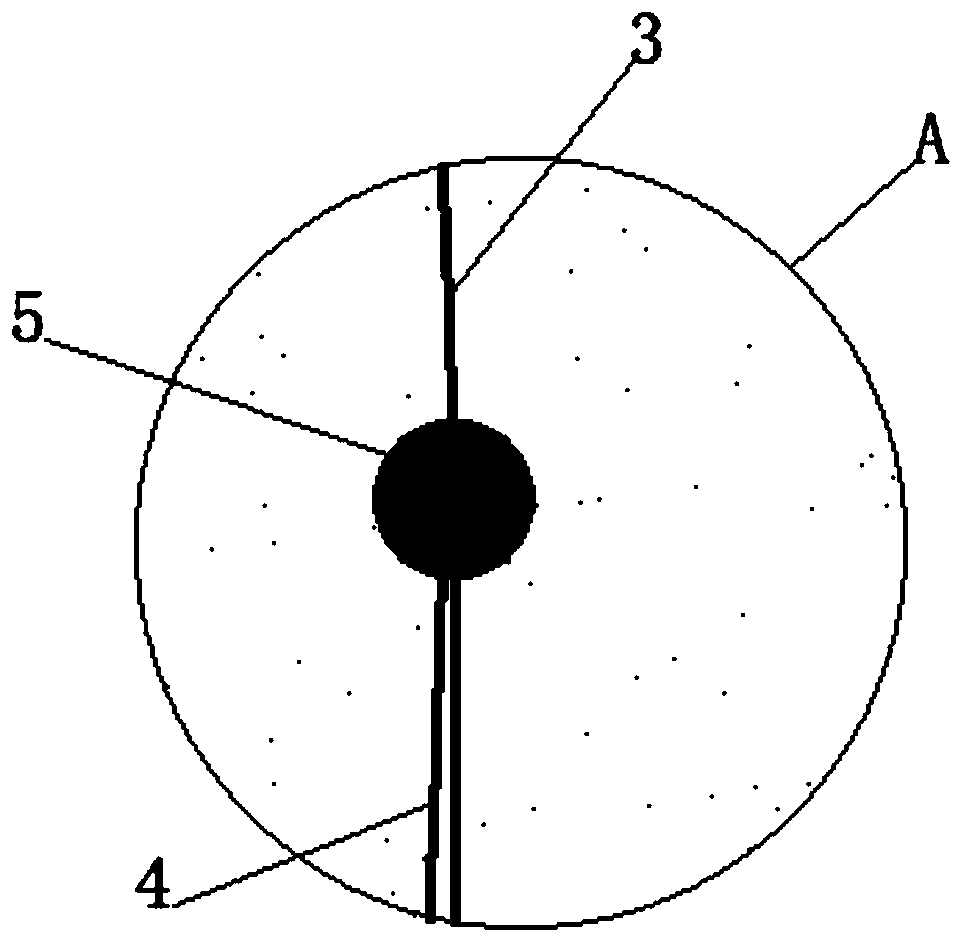

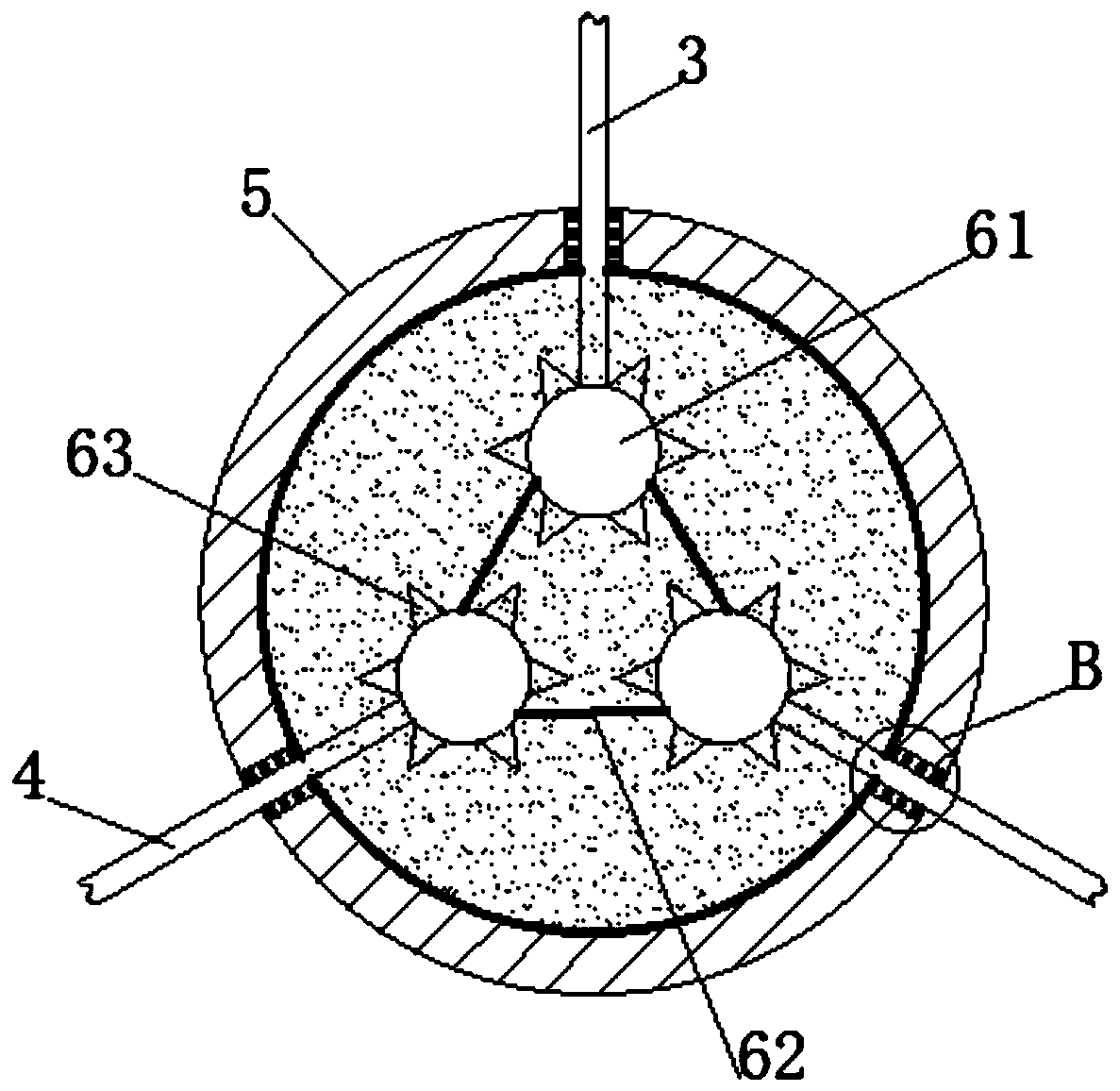

[0045] see figure 2 , there are pre-rupture points 5 connected between a plurality of branch wires 4 and trunk wires 3, and the number of branch wires 4 connected to each pre-break point 5 is 1-2, and the branch wires 4 and the trunk The drawing wires 3 are evenly distributed on the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com