A vertical alignment device for brick-concrete structure walls in building construction

A brick-concrete structure and building construction technology, which is applied in building structure, building material processing, construction, etc., can solve the problems of inconvenient use, inability to intuitively respond to wall conditions, and inability to automatically mark, etc., so as to achieve reliable and convenient use , Convenient calibration work, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

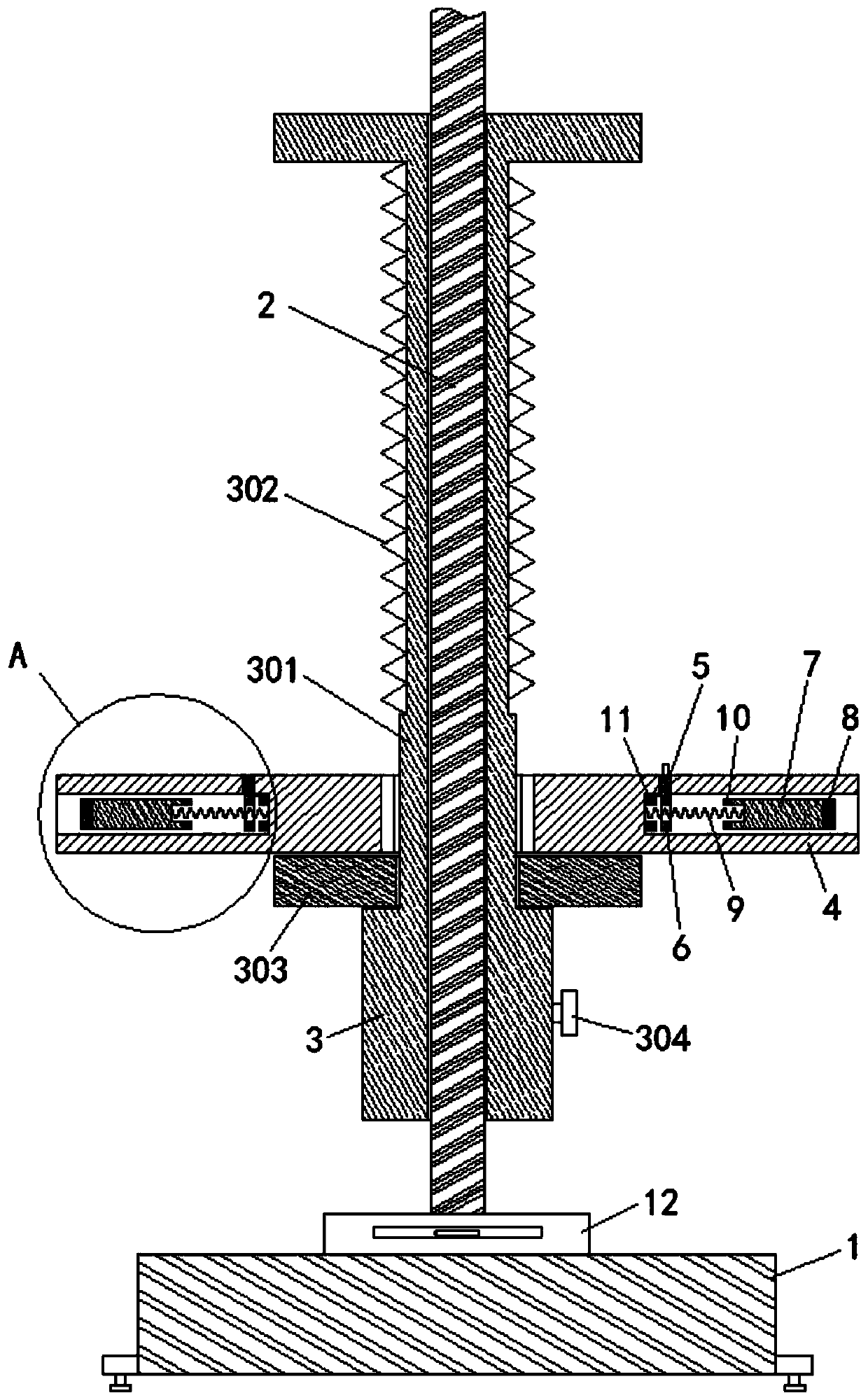

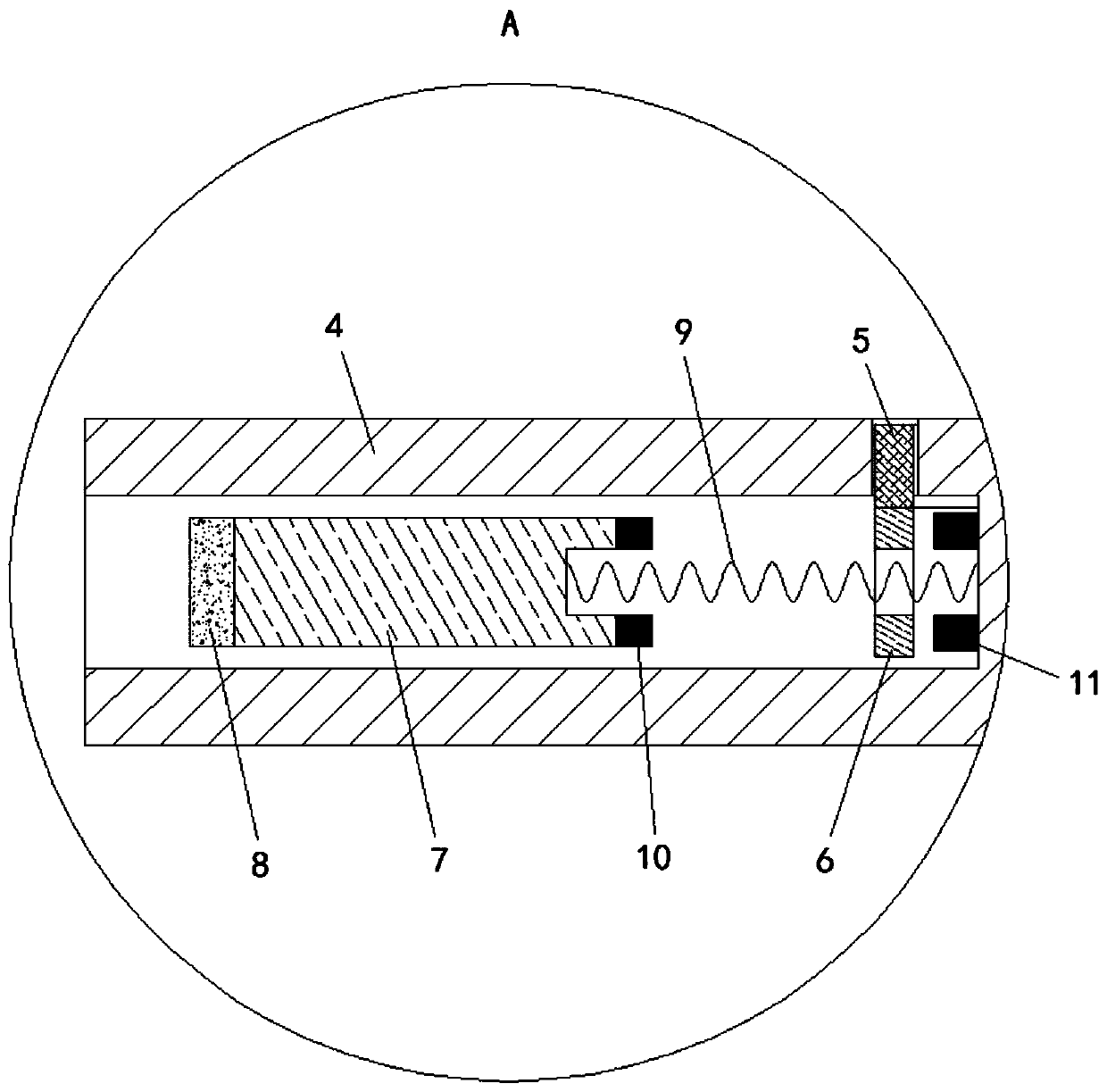

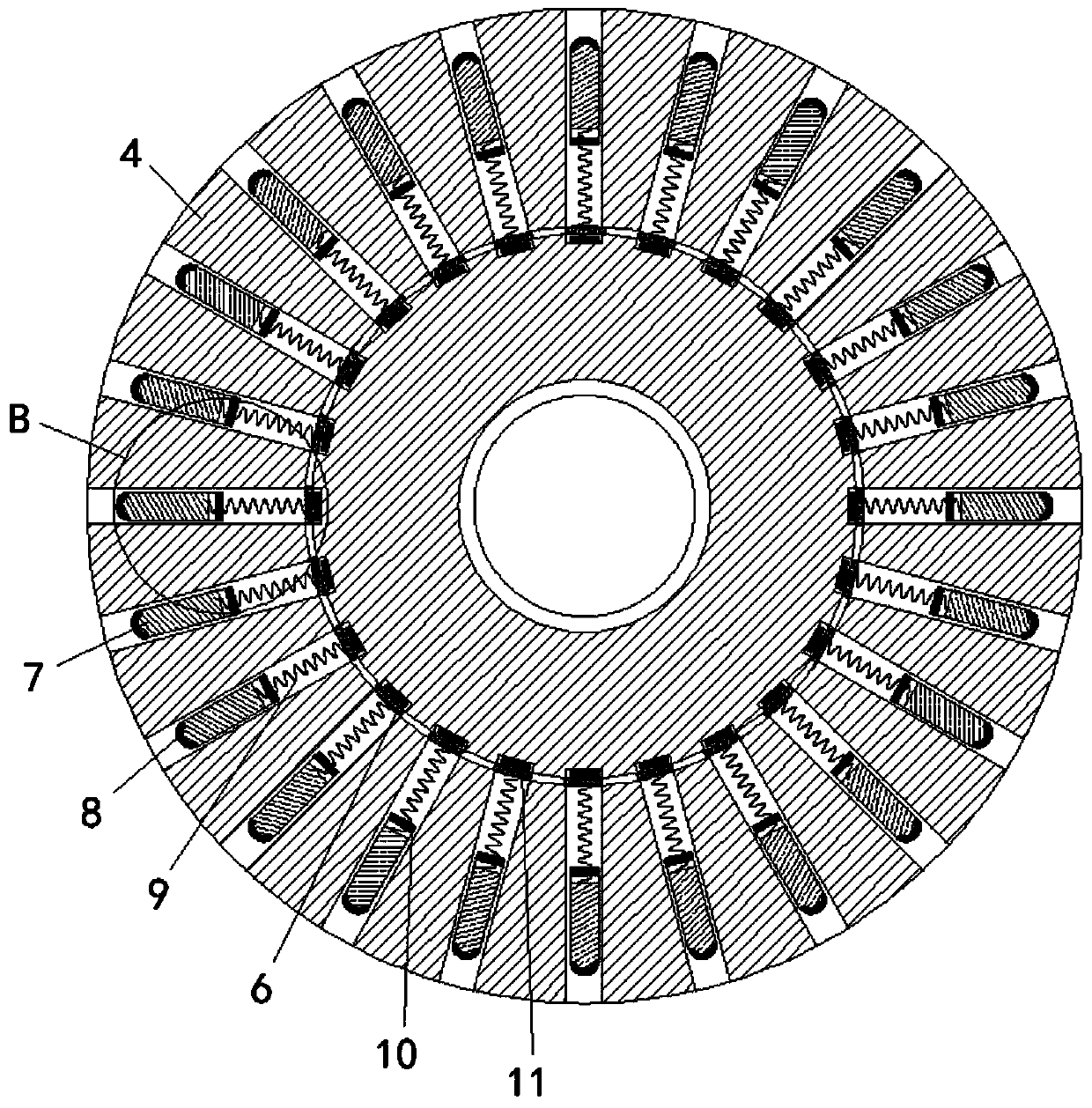

Embodiment 1

[0047] Before vertically aligning the brick-concrete structure wall, turn the swivel 5 so that the baffle 6 and the magnet are staggered, and the push plate 7 protrudes to the outside of the detection ring 4 under the repulsive force of the magnet, and the base 1 is fixed on the wall. Next to the body, make the detection cotton 8 close to the wall, adjust the base 1 by observing the level 12, ensure that the guide rod 2 is in a vertical state, and then push the slip ring 303 upwards to drive the detection ring 4 to rotate and move on the spiral section 302, if the wall If the body is vertical, the detection cotton 8 will not touch the wall during the upward movement. If the detection cotton 8 touches the wall, it means that the wall is skewed and needs to be corrected. The inside is filled with powder. When the detection cotton 8 touches the wall and is squeezed by the wall, the powder will stay on the wall and form a mark, so that the construction personnel can intuitively kno...

Embodiment 2

[0049] Since the outer surface of the brick-concrete wall is not smooth and has certain unevenness, the position of the detection cotton 8 can be adjusted, and the powder can also be replaced with a liquid paint that is easy to fade, so that it is convenient to add marking materials. At this time, the detection cotton 8 can be closely attached to the wall. If the wall is vertical, then when the detection ring 4 moves up and down, the marks left by the detection cotton 8 on the wall are all of the same depth. If it is too deep or too shallow, it means that the wall is skewed, and the skew can also be directly judged, which is convenient for construction personnel to correct.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com