Solvent exchange system

A technology of solvent exchange and solvent tank, which is applied in the direction of liquid variable capacity machinery, pump control, pump device, etc., can solve the problems of sample contamination, failure of automatic control, low efficiency of manual operation, etc., and achieve the effect of easy disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

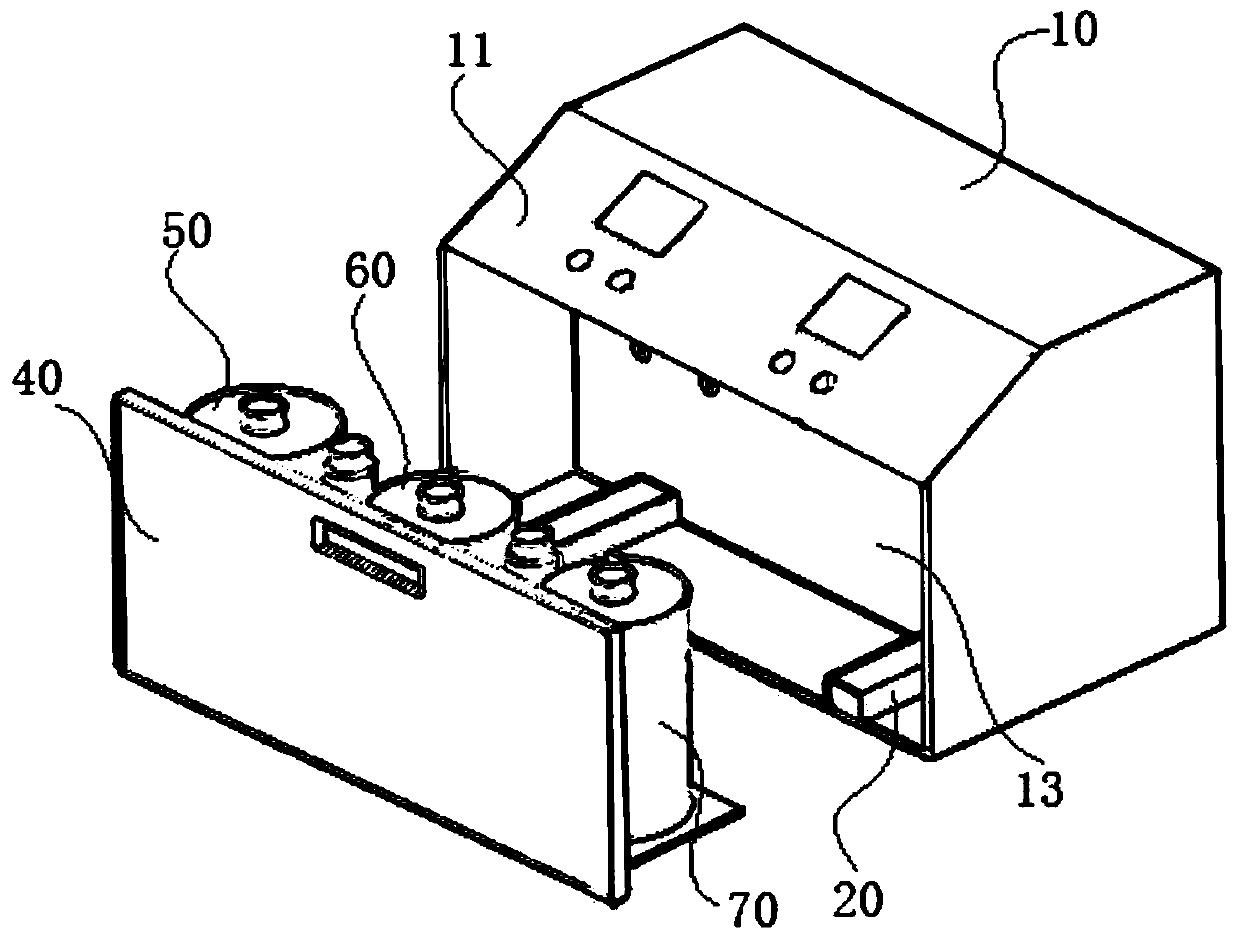

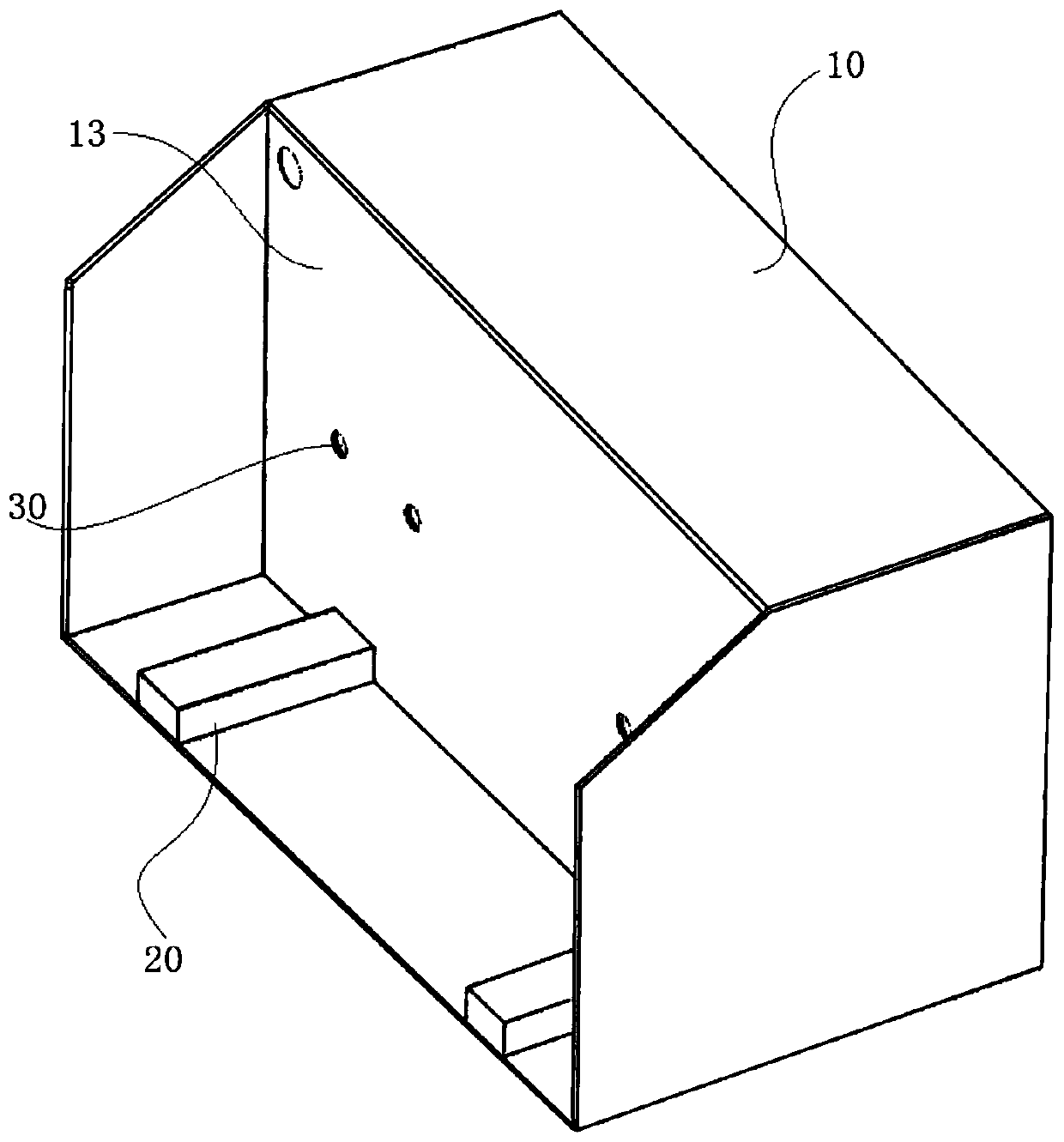

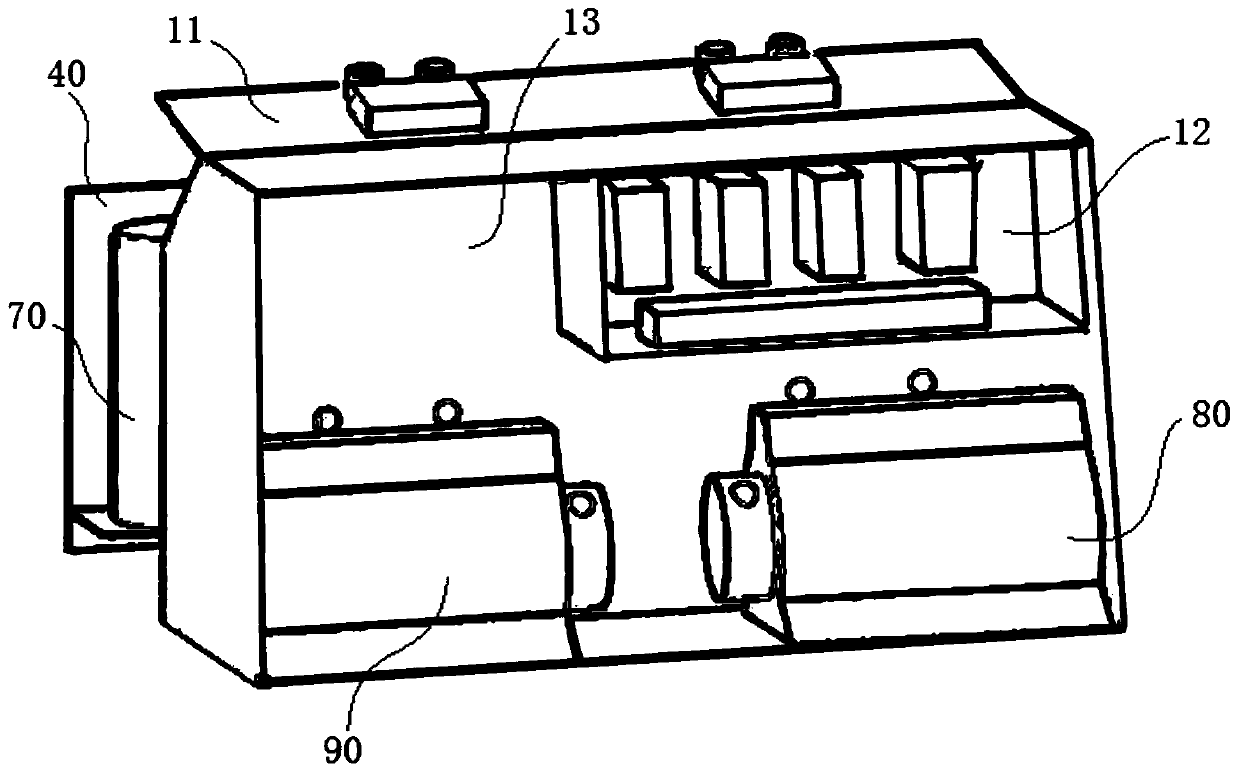

[0023] Such as figure 1 and as figure 2 As shown, the present invention provides a solvent exchange system, including a cabinet 10 and a base 40, the cabinet 10 and the base 40 form a drawer structure, the cabinet 10 is provided with a slide rail 20, and the base 40 is provided with There is a chute, and the chute and the slide rail 20 realize the sliding connection between the base body 40 and the cabinet body 10 , and the opening or closing cooperation between the base body 40 and the cabinet body 10 is realized by pulling or pushing the base body 40 .

[0024] The substrate 40 is provided with an exchange solvent tank 50, a former solvent tank 60 and a waste liquid tank 70. The former solvent tank 60 is used to contain solvents and samples that need to be replaced with a solvent, and the exchange solvent tank 50 is filled with new solvents. The waste liquid tank 70 is used To collect the waste liquid that needs to be discharged, when the base body 40 slides relative to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com