Heat pump for washing machine

A washing machine and heat pump technology, which is applied in the field of household appliances, can solve problems affecting the continuity of the heat pump system, and achieve the effects of simple structure, fast drying, and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The process embodiment is described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to make a clearer and clearer definition of the protection scope of the present invention.

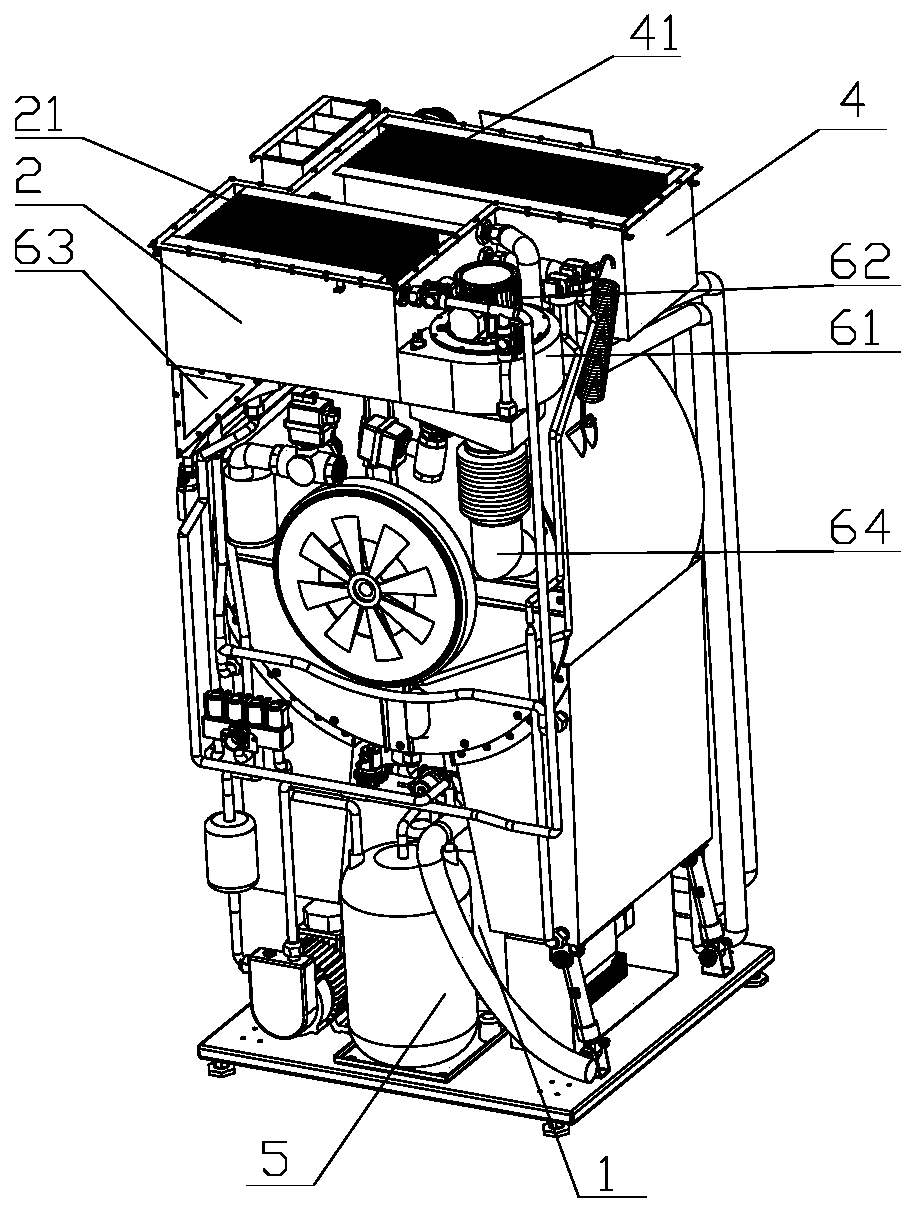

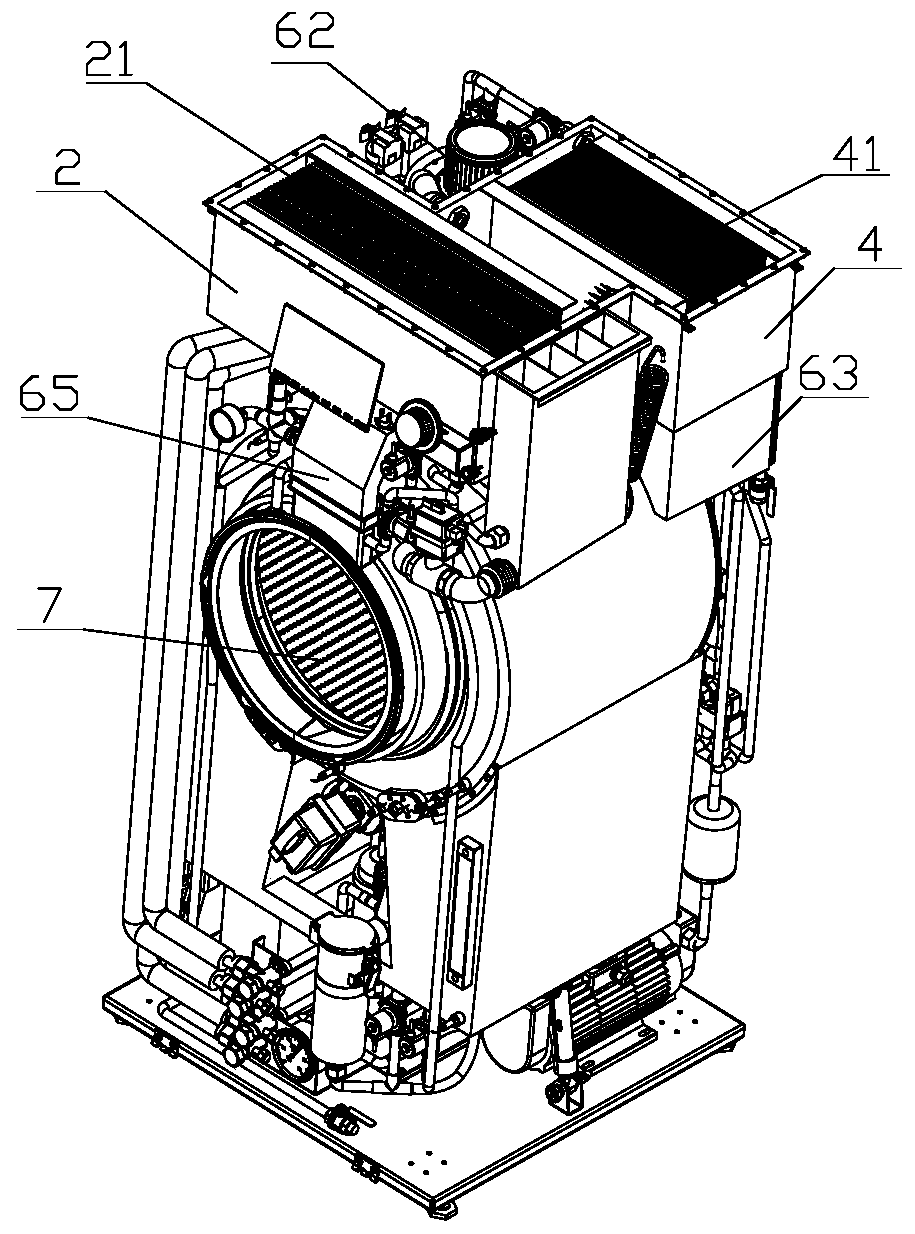

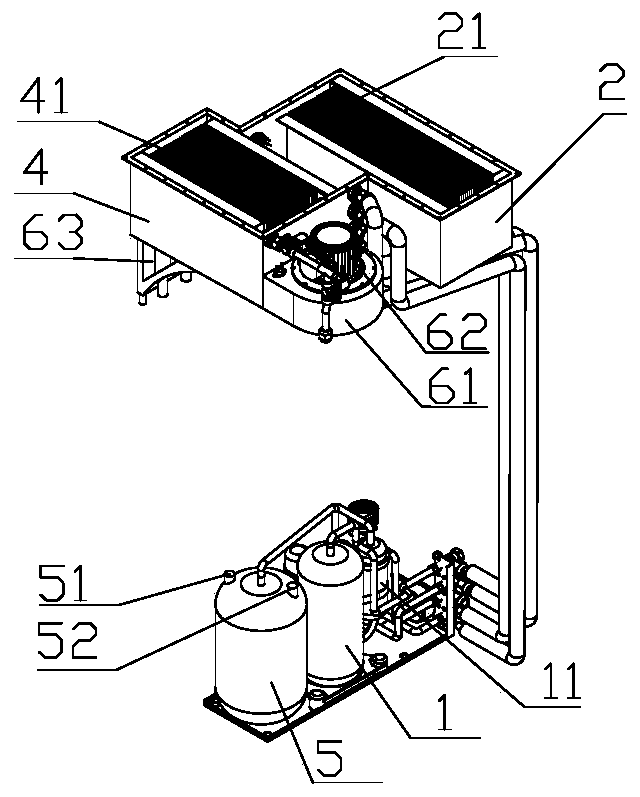

[0030] As attached figure 1 First view structural schematic diagram of washing machine using heat pump of the present invention, attached figure 2 The second perspective structural diagram of the washing machine using the heat pump of the present invention, attached image 3 The first view structural diagram of the present invention and attached Figure 4 As shown in the schematic structural diagram from the second perspective of the present invention, a heat pump for a washing machine of the present invention includes a compressor 1, a condenser 2, a throttle valve 3, and an evaporator 4 connected in series through a pipeline, and a refrigerant is installed on one side of the compressor 1 Tank 11, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com