Vacuum chamber high-voltage power supply leading-in device

A high-voltage power supply and introduction device technology, applied in electrical components, accelerators, etc., can solve the problems of difficult to shield electric field and high-voltage discharge, unable to shield discharge, affecting the normal operation of electron accelerators, etc., to ensure normal operation and avoid high-voltage discharge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

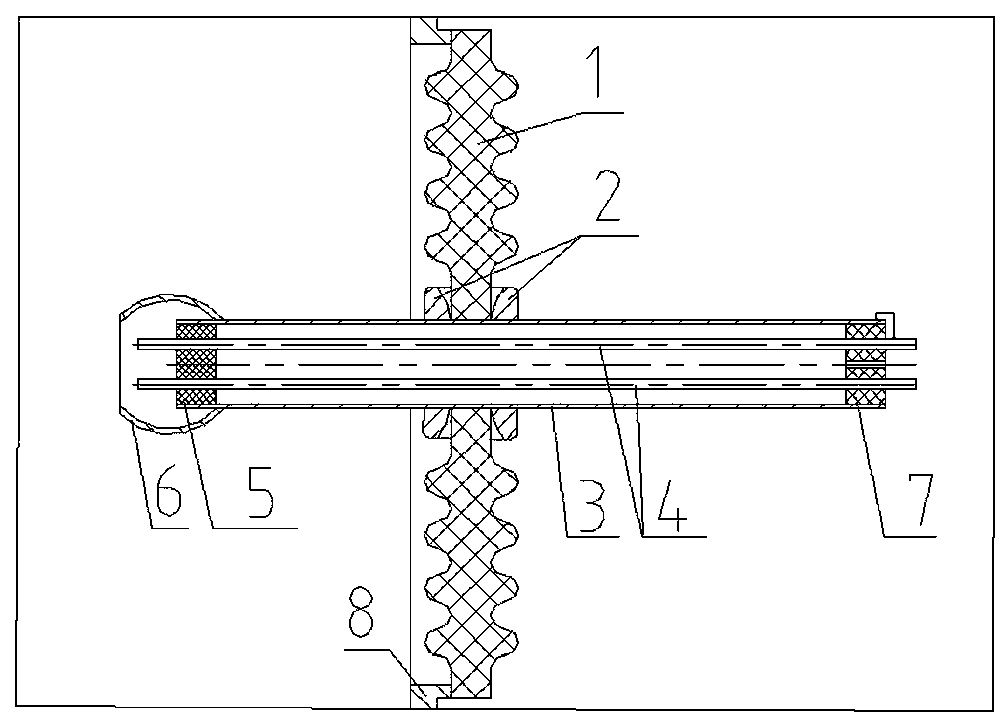

[0014] like figure 1 As shown, the vacuum chamber high-voltage power supply introduction device of the present invention includes a vacuum chamber, and a mounting hole is processed on the wall 8 of the vacuum chamber, and a first insulating flange 1 is installed in the mounting hole. The first insulating flange is a flange plate made of No. 95 ceramics, the center of which is flat on both sides and equipped with rubber sealing rings for isolating vacuum and gas. A high voltage bushing 3 is installed inside the first insulating flange 1 . The high-voltage bushing 3 is made of No. 304 stainless steel, and its two ends extend into the vacuum chamber and the outside of the vacuum chamber respectively. The high-voltage bushing 3 on both sides of the first insulating flange 1 is covered with shielding rings 2. The shielding Ring 2 is a metal ring supported by No. 304 stainless steel with an arc-shaped side. The arc-shaped surfaces of the two shielding rings face the plane at the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com