Frame-type adapter board and its preparation method, circuit board device and electronic equipment

A frame type, adapter board technology, applied in the direction of printed circuit, printed circuit components, printed circuit structural connection, etc., can solve the problems of high cost and complex preparation process, and achieve low cost, simple manufacturing process and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] Based on the frame-type adapter plate disclosed in the embodiment of the present invention, the embodiment of the present invention discloses a method for preparing a frame-type adapter plate. The disclosed preparation method includes:

[0065] Step 1, plastic-encapsulate the metal electrical connection part 200 to form the plastic-encapsulation part 500, such as Figure 4 shown;

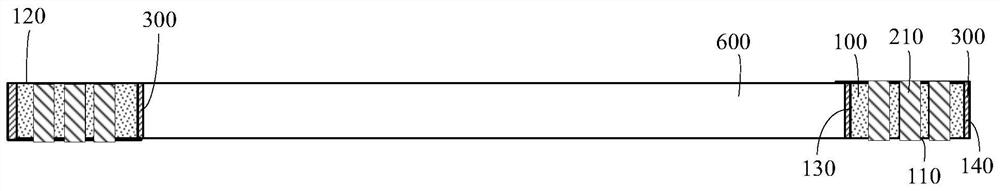

[0066] Step 2, opening a through hole 600 on the plastic sealing part 500, such as Figure 5 As shown, the plastic package part 500 forms the frame type plastic package part 100 through the through hole 600 , and the metal electrical connection part 200 is disposed in the frame type plastic package part 100 .

[0067] Step 3: Remove part of the plastic sealing part 500, and the two ends of the metal electrical connection part 200 are respectively exposed to the first plate surface 110 and the second plate surface 120 of the frame type plastic sealing part 100 distributed oppositely, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com