Blind-mating grounding clamping piece structure of electrical cabinet box

A grounding clip and sheet structure technology, applied in the printed circuit grounding device, electrical equipment shell/cabinet/drawer, electrical components, etc., can solve the problems of overall rigidity reduction, inability to loosen socket pin, socket pin shaking, etc. The effect of reducing the number of parts, reducing the cost of the chassis, and facilitating the production and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can more clearly understand how to practice the present invention. While the invention has been described in connection with preferred specific embodiments thereof, these embodiments are illustrative only and are not intended to limit the scope of the invention.

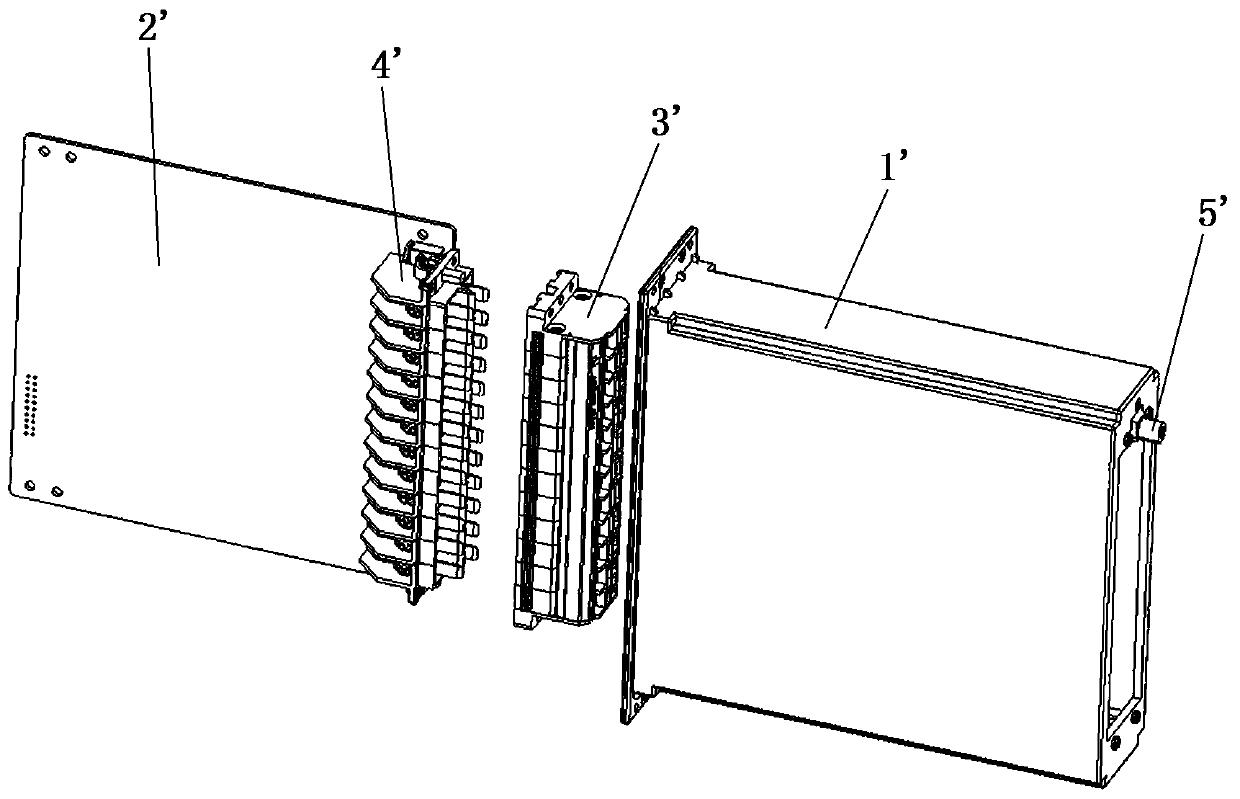

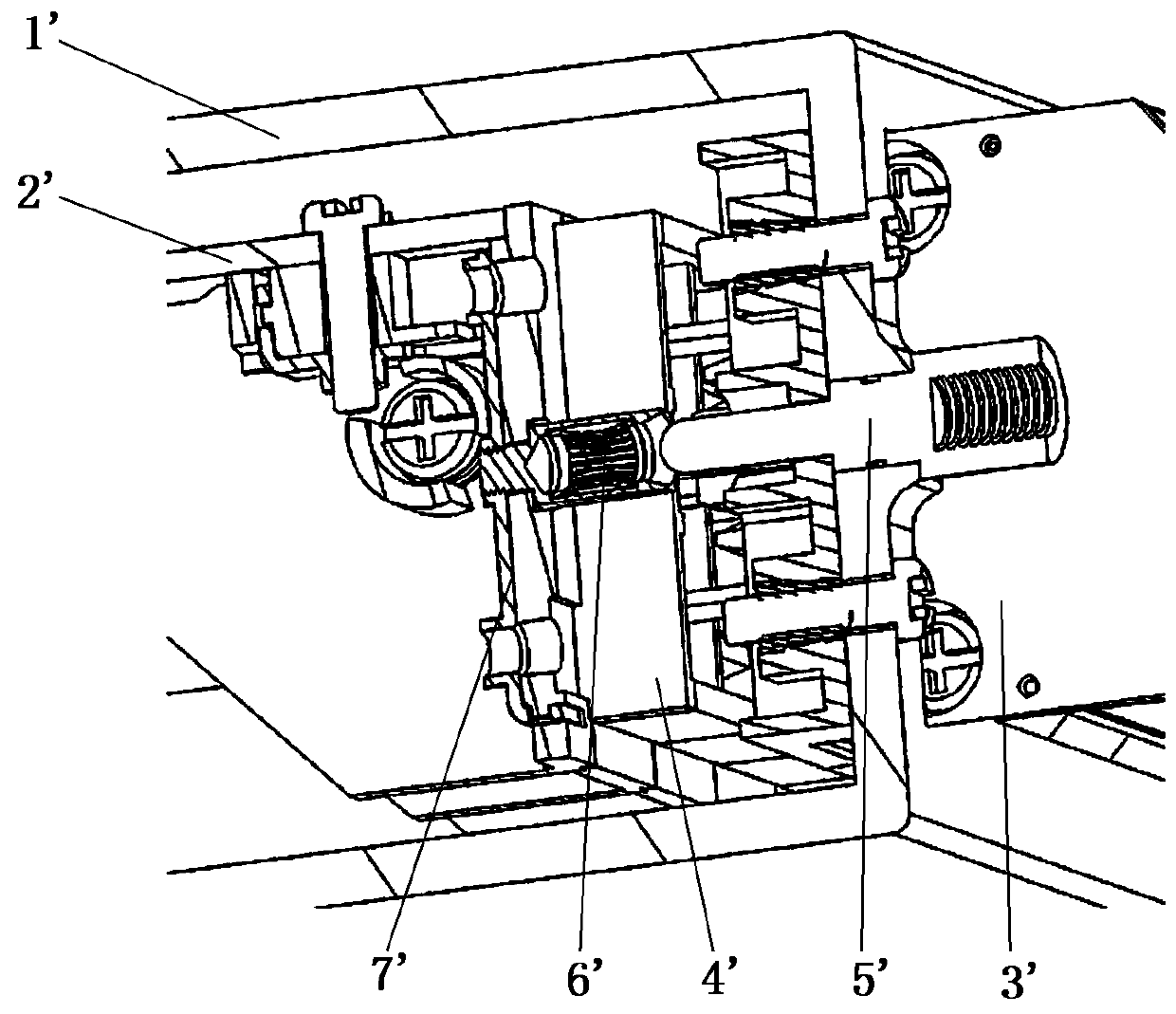

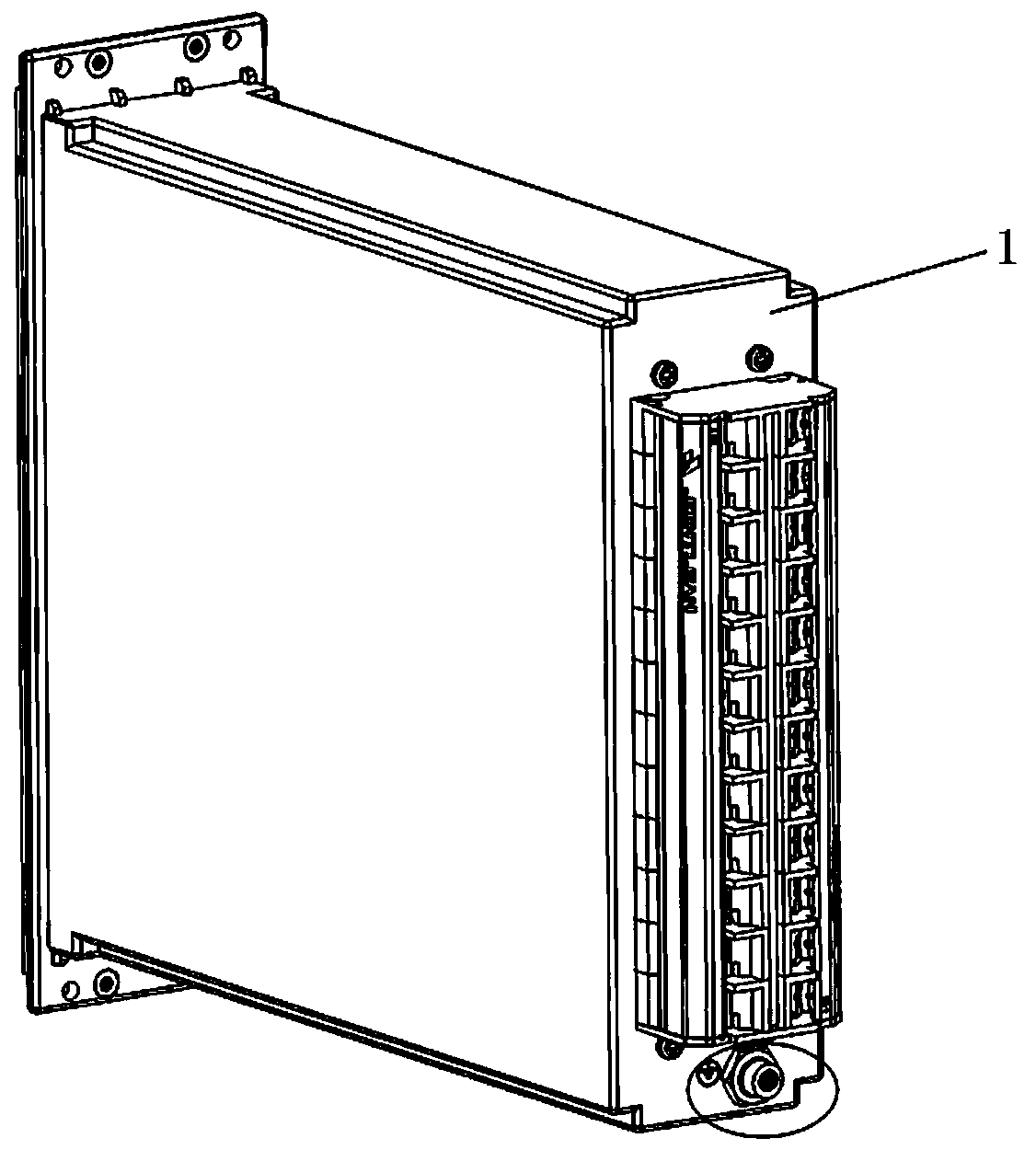

[0039] see image 3 with Figure 4 , a blind-mating grounding clip structure of an electrical cabinet chassis, comprising a plastic chassis shell 1, a PCB board 2, a chassis grounding wire interface post 3, a grounding conductive clip 4, an elastic booster reed 5, and a fastening nut 6.

[0040] The PCB board 2 is mounted on the inner side of the plastic case shell 1 , and the PCB board 2 is provided with a PCB board grounding electrode 201 .

[0041] The plastic case shell 1 is provided with a through hole, and the case ground wire interface post...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com