Turf meadow maintenance machine for landscape engineering

A turf and meadow technology, applied in the field of turf and meadow maintenance machines, can solve the problems of short supply of turf, waste of resources, low survival rate, etc., and achieve the effects of saving manpower, reducing floor space and high survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

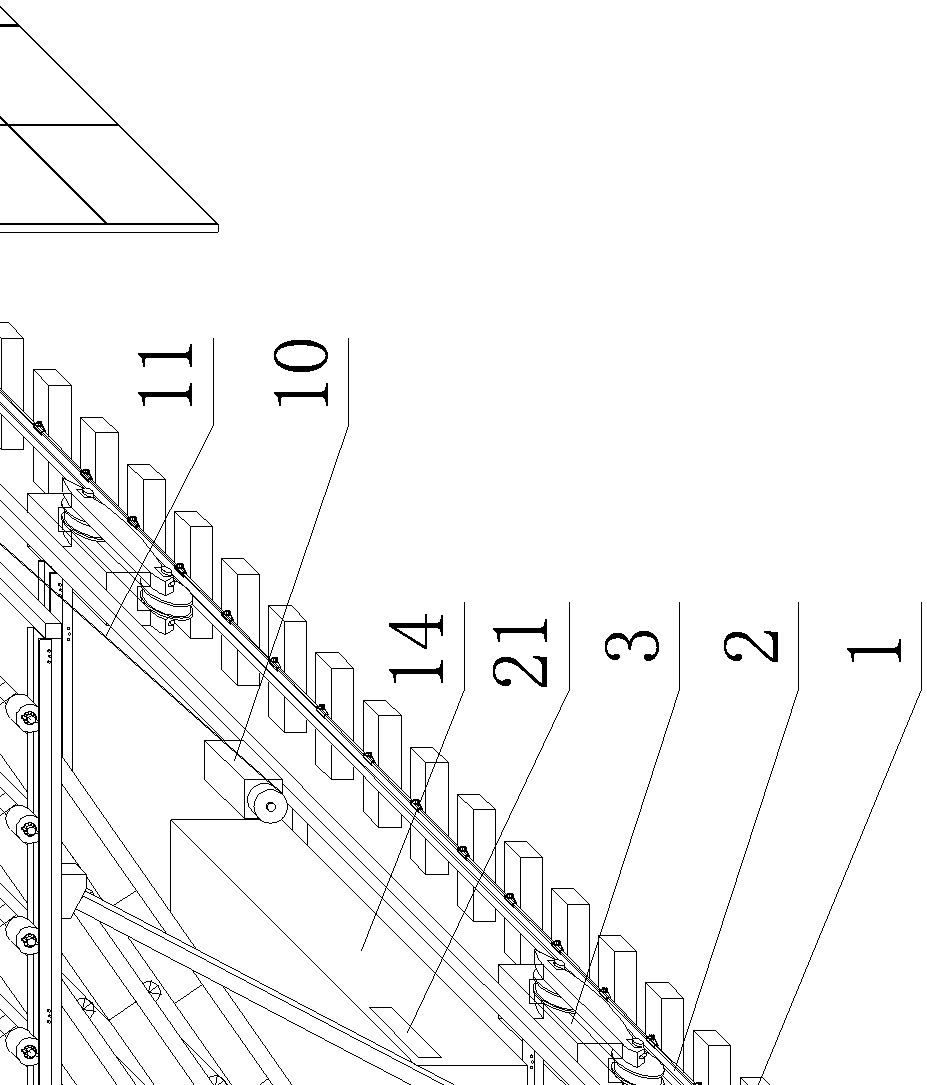

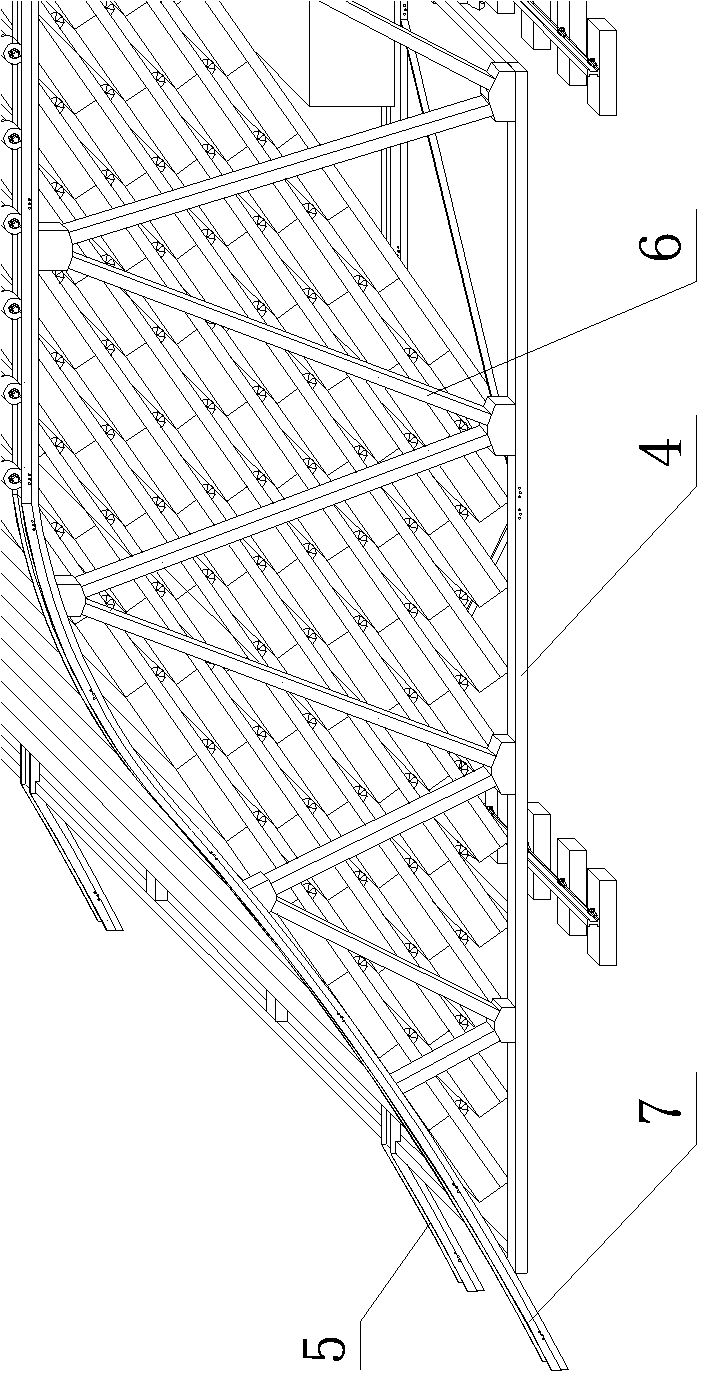

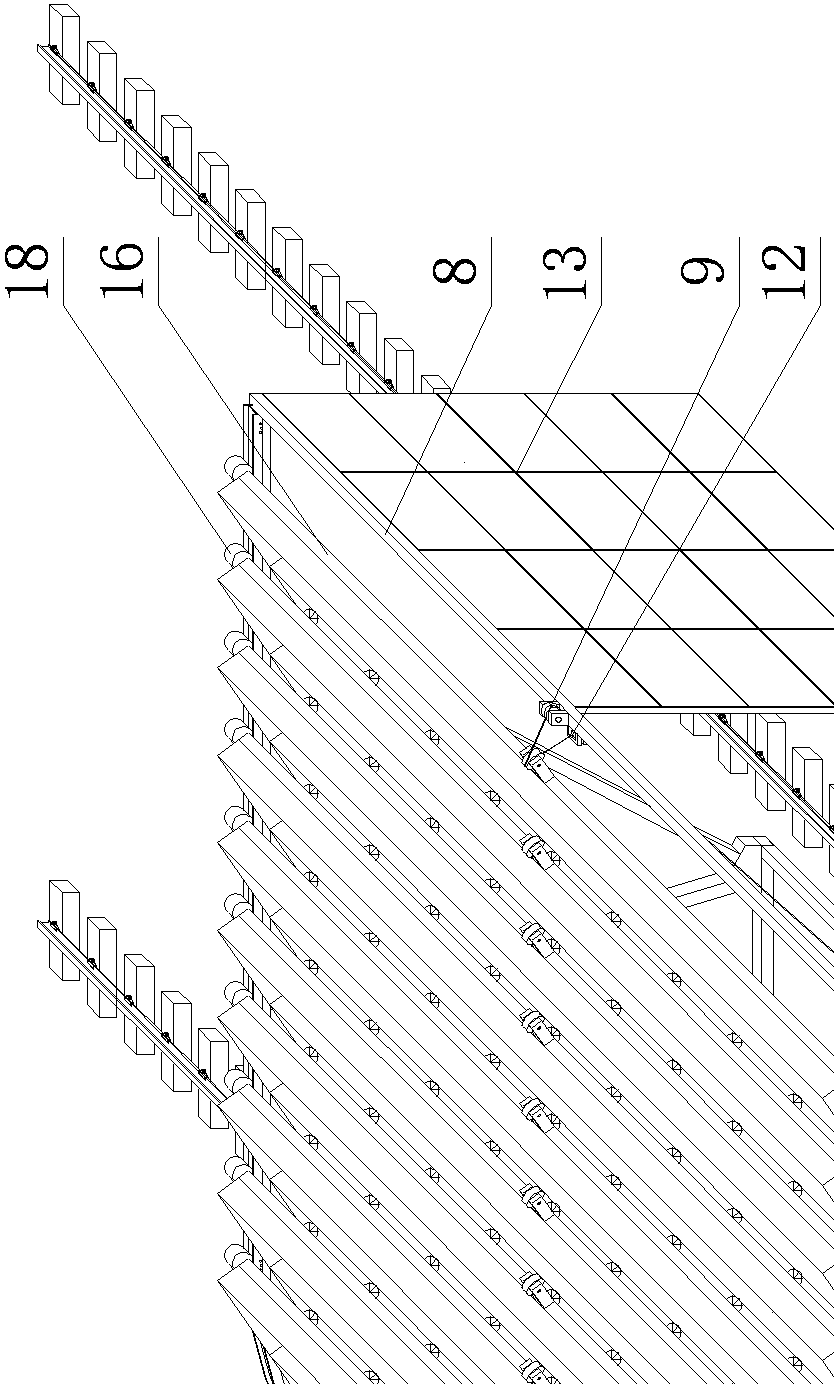

[0051] This embodiment provides a turf meadow maintenance machine for greening projects, such as figure 1 , figure 2 and image 3As shown, the turf and meadow maintenance machine is composed of slide rails, maintenance trays and structures. The slide rail is composed of a sleeper 1 and a track 2; the sleeper 1 can be made of prefabricated concrete components; the track 2 can be an I-shaped steel track; the sleeper 1 and the track 2 can be connected by a spring fastener; the maintenance plate, It is a frame structure box chamber member with a spraying system 15, consisting of a spraying system 15, a pan bottom structure 16, a pan chamber plate 17, a top pulley 18, a bottom pulley 19 and a movable pulley 20; For load-bearing function, a sprinkler system 15 for maintenance is provided at the bottom of the maintenance tray, a panel chamber composed of equidistant panel chamber plates 17 is arranged on the structure to maintain the turf meadow, and a movable pulley 20 is arrange...

no. 2 example

[0055] The working process of this embodiment is as follows:

[0056] The working process of this embodiment is almost the same as that of the first embodiment, and the site used and the object of maintenance are slightly changed. In the early stage of municipal greening project construction, in the turf cultivation field, select a site suitable for the erection requirements of the turf meadow maintenance machine According to the steps of the first embodiment, the turf meadow maintenance machine is set up to strip and maintain the turf cultivated in the turf cultivation field, and the second round of planting and cultivation of the turf can be realized in the vacant turf cultivation field.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com