Ultralow-temperature freezing and sealing type preservation method

An ultra-low temperature freezing and ultra-low temperature preservation technology, applied in the preservation, application, animal husbandry and other directions of human or animal body, can solve the problems of the difficulty of maintaining the sterile state of liquid nitrogen, cross-infection of embryos, etc., to avoid misplacement, increase The effect of space utilization and avoiding re-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: prepare aseptic refrigerant

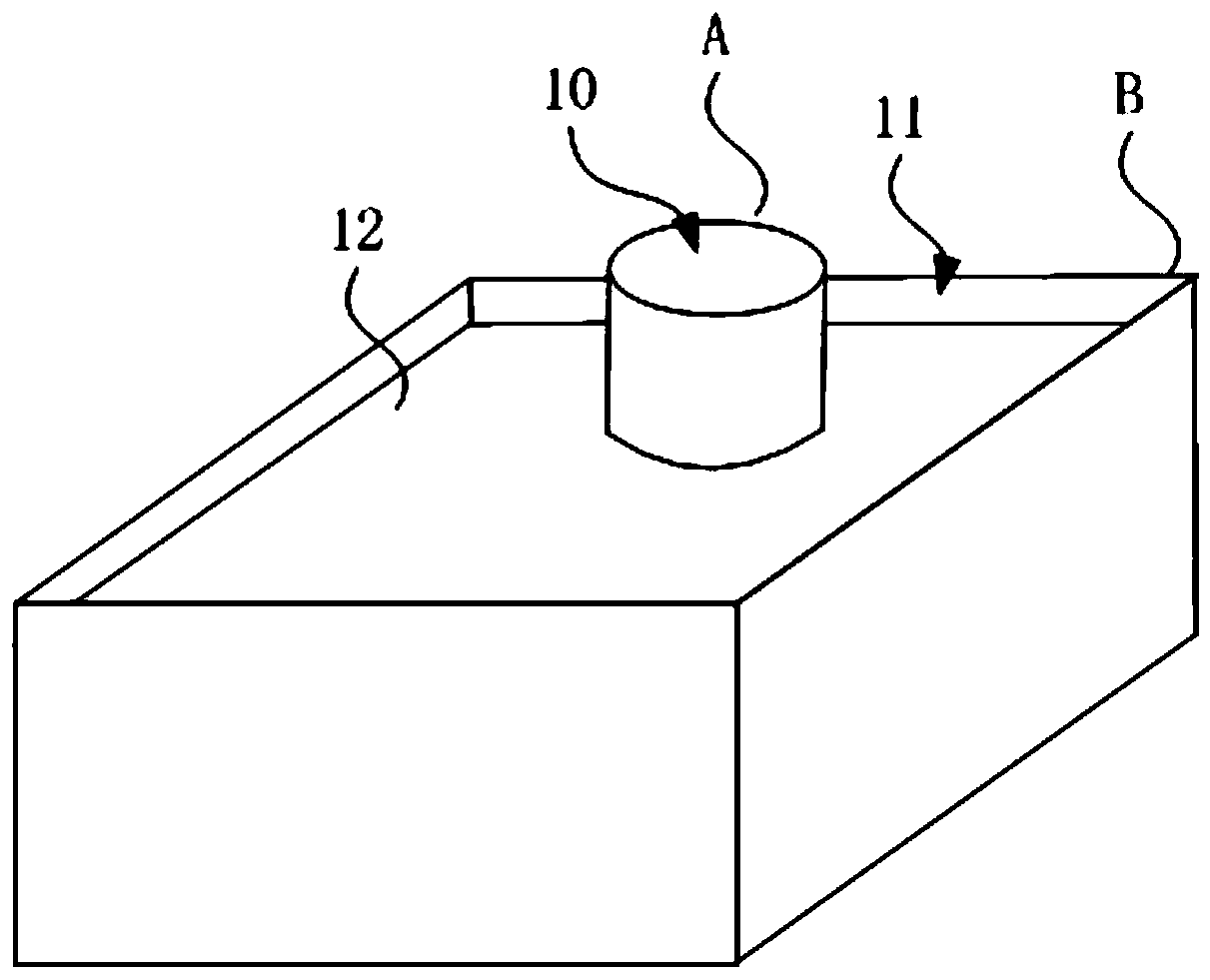

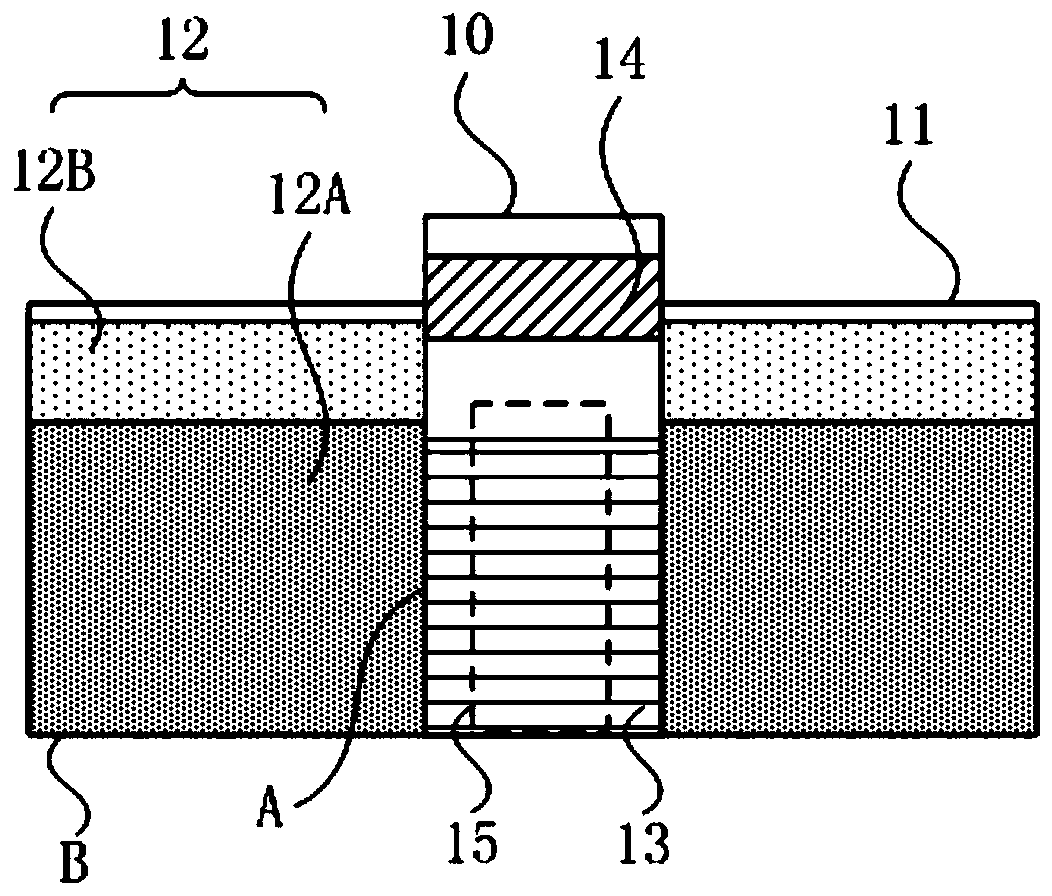

[0043] Step 1. Provide a container B. The container B is an open structure, wherein the opening of the container B is the second opening 11 . The size of the container B can also be selected according to requirements, which is not limited in the present invention. In this embodiment, the container B is a foam box with a length of 260mm*width of 150mm*depth of 115mm without a cover. An initial cold source 12 is contained in the container B. In this embodiment, the initial cold source 12 contained in the container B is commercially available liquid nitrogen. The initial cooling source 12 has a liquid layer 12A and a vapor layer 12B above the liquid layer 12A, wherein the vapor layer 12B is formed by volatilization of the liquid layer 12A. In order to clearly show the difference between the two, the liquid layer 12A and the vapor layer 12B are drawn with different hatching in the drawings. Specifically, the depth of the cont...

Embodiment 2

[0051] Embodiment 2: Aseptic refrigerant composition and temperature measurement

[0052] The liquid air prepared in the plastic tube in Example 1 was placed at room temperature, the vaporized air was introduced into a vacuumized aluminum foil bag, and the proportion of nitrogen in the liquid air was measured by gas chromatography. Gas chromatograph adopts Agilent6890, equipped with TCD detector, carbon molecular sieve packed column, 2m×2mmID, carrier gas is nitrogen, carrier gas flow rate: 20mL / min, column temperature 40°C, run time 5min. Injection method: gas valve injection, quantitative tube volume 1mL, sample filling time 0.5min, sampling time 0.5min.

[0053] As a result of the measurement, the nitrogen content in the obtained liquid air is about 85.5%. The ultra-low temperature thermometer measures the temperature of liquid air at about -195°C. Using liquid air as a refrigerant, you can use liquid nitrogen as a cold source anytime and anywhere to prepare sterile refri...

Embodiment 3

[0054] Embodiment 3: Aseptic refrigerant contamination test

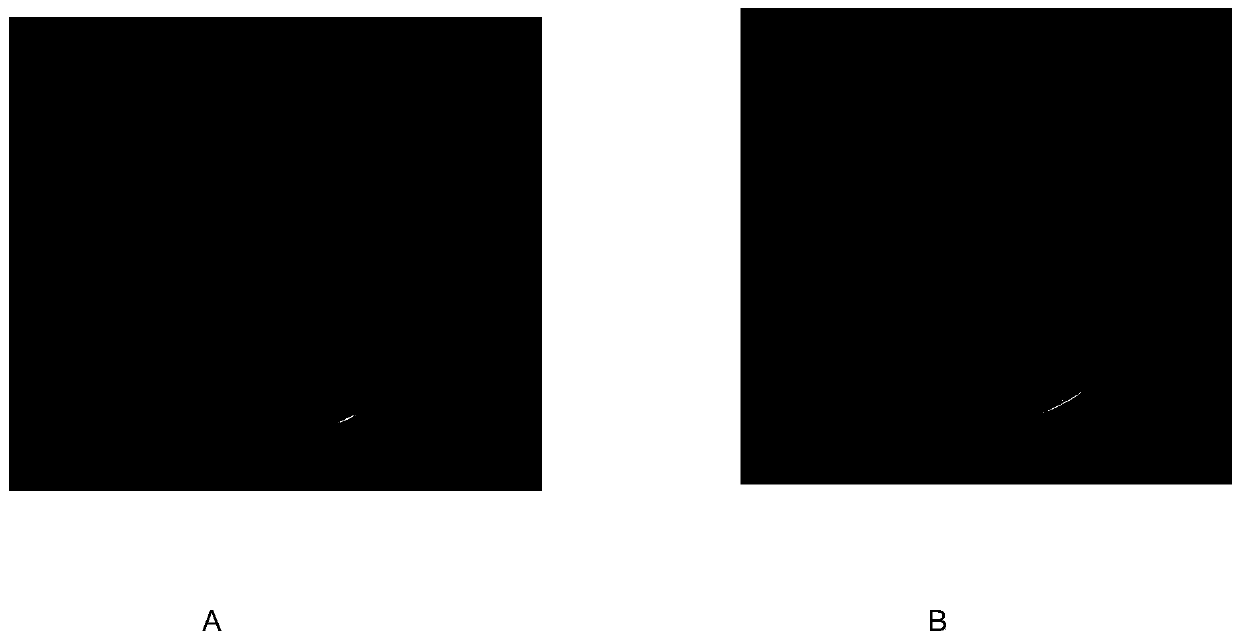

[0055] Prepare aseptic liquid air as described in Example 1. After repeatedly dipping the liquid air with a sterile cotton swab, apply the sample (experimental group) dipped by the cotton swab on a Columbia blood plate, place at 35°C, 5% CO 2 Cultivate in the incubator for 48 hours, and observe the bacterial growth. Take 10 milliliters of the initial cold source liquid nitrogen used to prepare the sterile liquid air as a control (control group). The results showed that there were two kinds of yellow and off-white colonies growing on the blood plate of the control group ( image 3 A), while the experimental group had no colony growth (attached image 3 B). Further, the two colonies of the experimental group were isolated and purified, Gram staining and molecular identification showed that the yellow colonies were Gram-positive cocci under the bacterial microscope, and were identified as Neomicrococcus aestuarii st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com