Carbon-filled modified acrylate rubber as well as composition and preparation method thereof

An acrylate and carbon modification technology, which is applied in the field of acrylate rubber, can solve the problems of acrylate rubber strength reduction, poor low temperature resistance and mechanical properties, and unsatisfactory effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

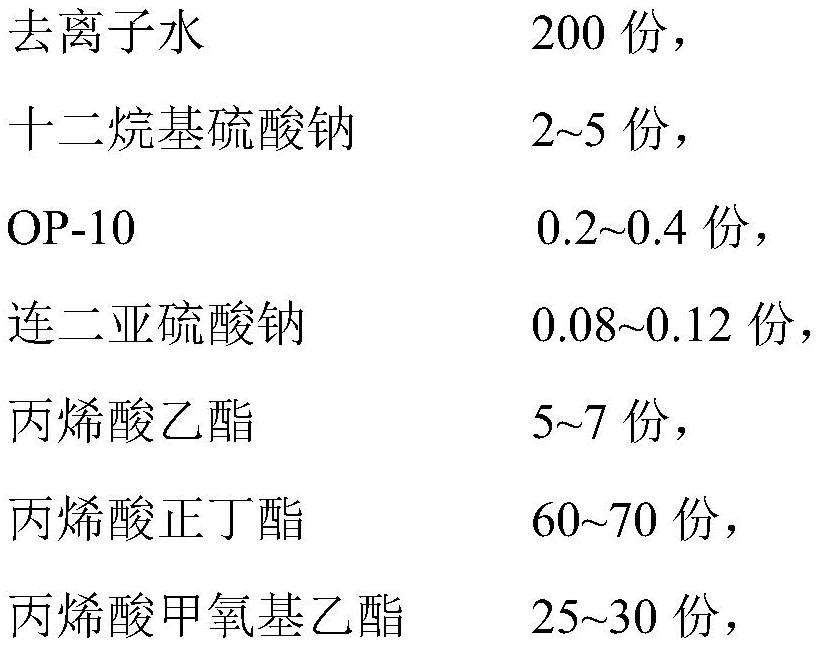

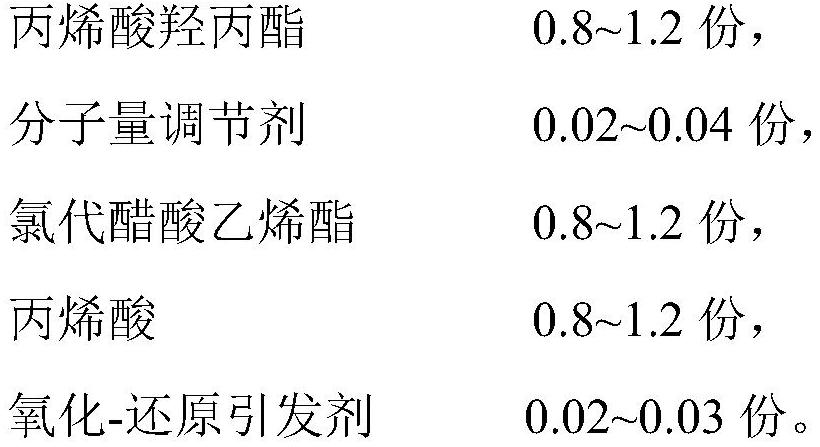

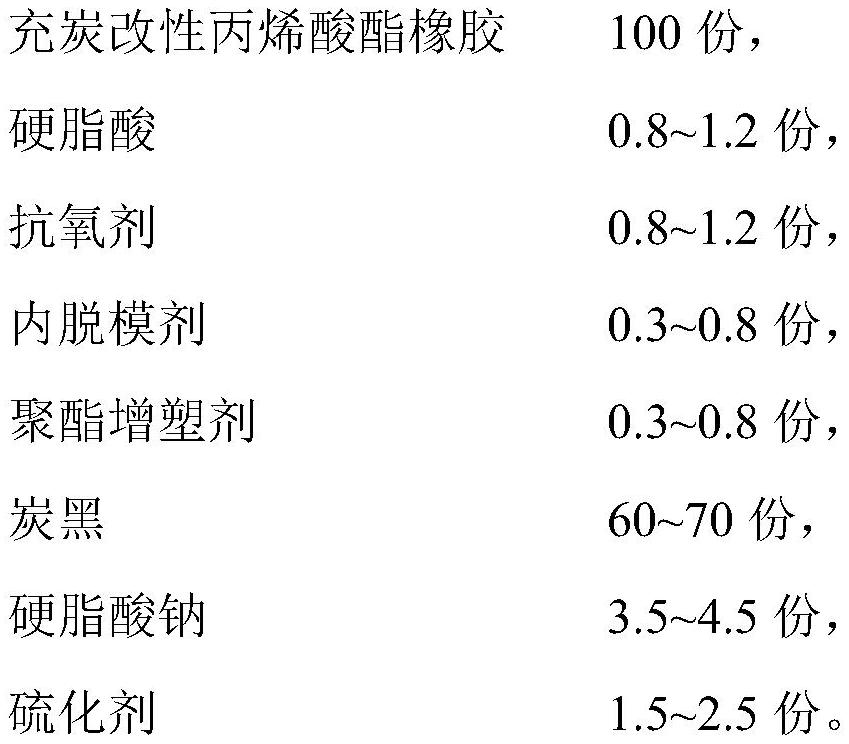

Method used

Image

Examples

Embodiment 1

[0040] (1) Preparation of modified carbon black dispersion:

[0041] Assemble a 500ml reaction flask in an ice-water bath, mix 5g of N330 and 3g of sodium nitrate with 220ml of concentrated sulfuric acid, and add 30g of potassium perchlorate under stirring. After stirring for 30 min at 10°C, the ice bath was removed, the reaction flask was transferred to a magnetic stirrer, and the magnetic stirring was continued for 48 h. After that, 300 ml of deionized water was slowly added in 8 times, the temperature was raised to about 98 °C, and after stirring for 40 min, an appropriate amount of hydrogen peroxide was added to reduce the residual oxidant. Suction filtration while hot, and successively washed with 5% HCl solution and deionized water until the pH of the separation solution is 5-6. The obtained dispersion was ultrasonically dispersed for 1 h, and then freeze-dried to obtain hydrophilic modified N330. A 1 mg / ml hydrophilic modified N330 dispersion was prepared with 1% sodi...

Embodiment 2

[0049] (1) Preparation of modified carbon black dispersion:

[0050]Assemble a 500ml reaction flask in an ice-water bath, mix 5g of N330 and 4g of sodium nitrate with 200ml of concentrated sulfuric acid, and add 25g of potassium perchlorate under stirring. ℃, after stirring for 30 min, the ice bath was removed, the reaction flask was transferred to a magnetic stirrer, and the magnetic stirring was continued for 36 h. After that, 300ml of deionized water was slowly added in 8 times, the temperature was raised to about 95°C, and after stirring for 50min, an appropriate amount of hydrogen peroxide was added to reduce the residual oxidant. Suction filtration while hot, and successively washed with 5% HCl solution and deionized water until the pH of the separation solution is 5-6. The obtained dispersion was ultrasonically dispersed for 1 h, and then freeze-dried to obtain hydrophilic modified N330. A 2 mg / ml hydrophilic modified N330 dispersion was prepared with 1% sodium dodecy...

Embodiment 3

[0059] (1) Preparation of modified carbon black dispersion:

[0060] Assemble a 500ml reaction flask in an ice-water bath, mix 5g of N330 and 3.5g of sodium nitrate with 210ml of concentrated sulfuric acid, and add 28g of potassium perchlorate under stirring. Above 10 °C, after stirring for 30 min, the ice bath was removed, and the reaction flask was transferred to a magnetic stirrer, and the magnetic stirring continued for 48 h. After that, 300 ml of deionized water was slowly added in 8 times, the temperature was raised to about 98 °C, and after stirring for 40 min, an appropriate amount of hydrogen peroxide was added to reduce the residual oxidant. Suction filtration while hot, and successively washed with 5% HCl solution and deionized water until the pH of the separation solution is 5-6. The obtained dispersion was ultrasonically dispersed for 1 h, and then freeze-dried to obtain hydrophilic modified N330. A 1.5 mg / ml hydrophilic modified N330 dispersion was prepared wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com