Mixer capable of adjusting foam liquid ratio

A technology of foam liquid and mixer, which is applied in the direction of fluid mixer, mixer, mixing method, etc., can solve the problems of unstable working mixing ratio, insufficient foam liquid storage, large pressure loss, etc., and achieve high reliability and large The effect of foam liquid storage and avoiding water pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further explained below in conjunction with the drawings:

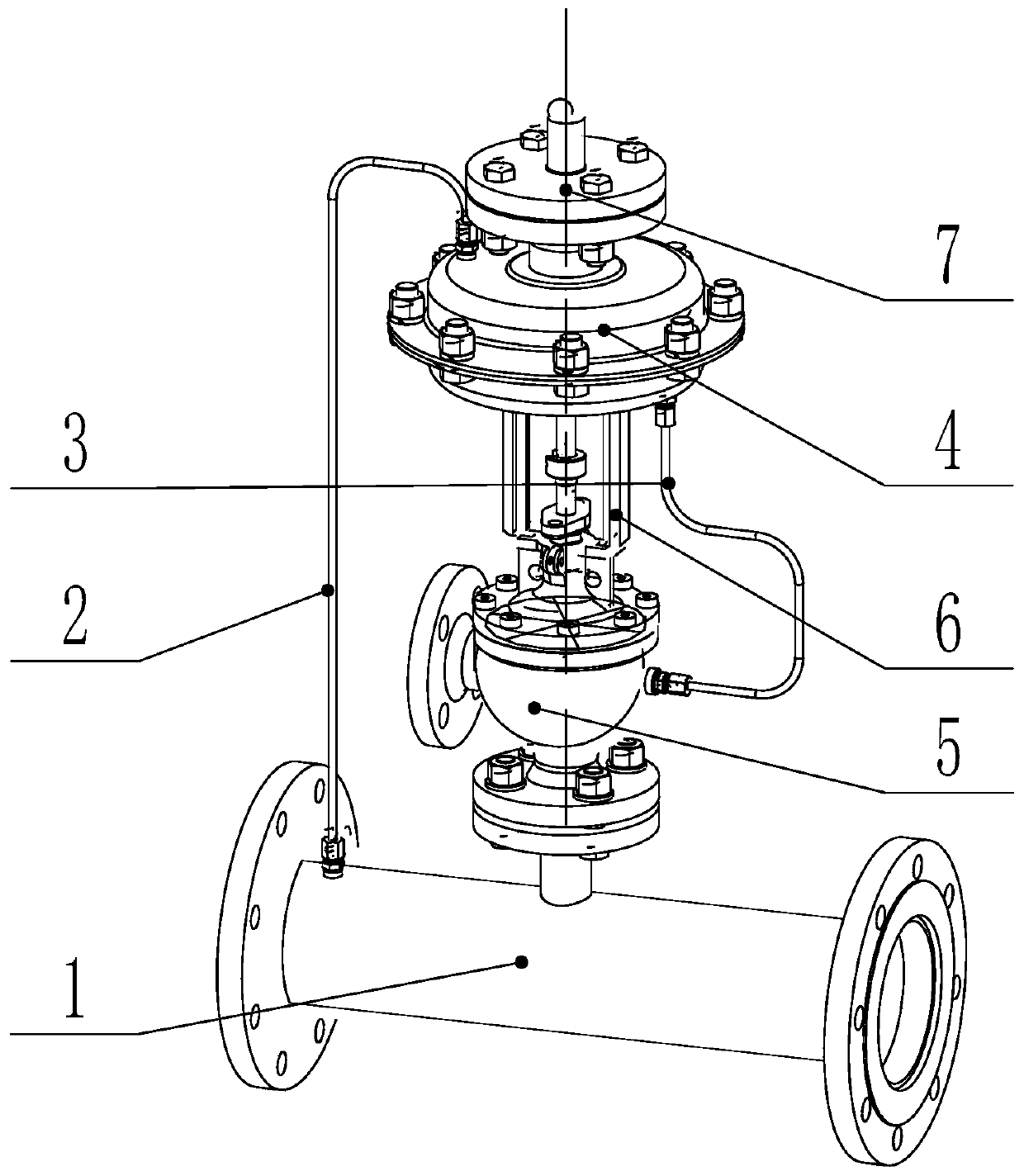

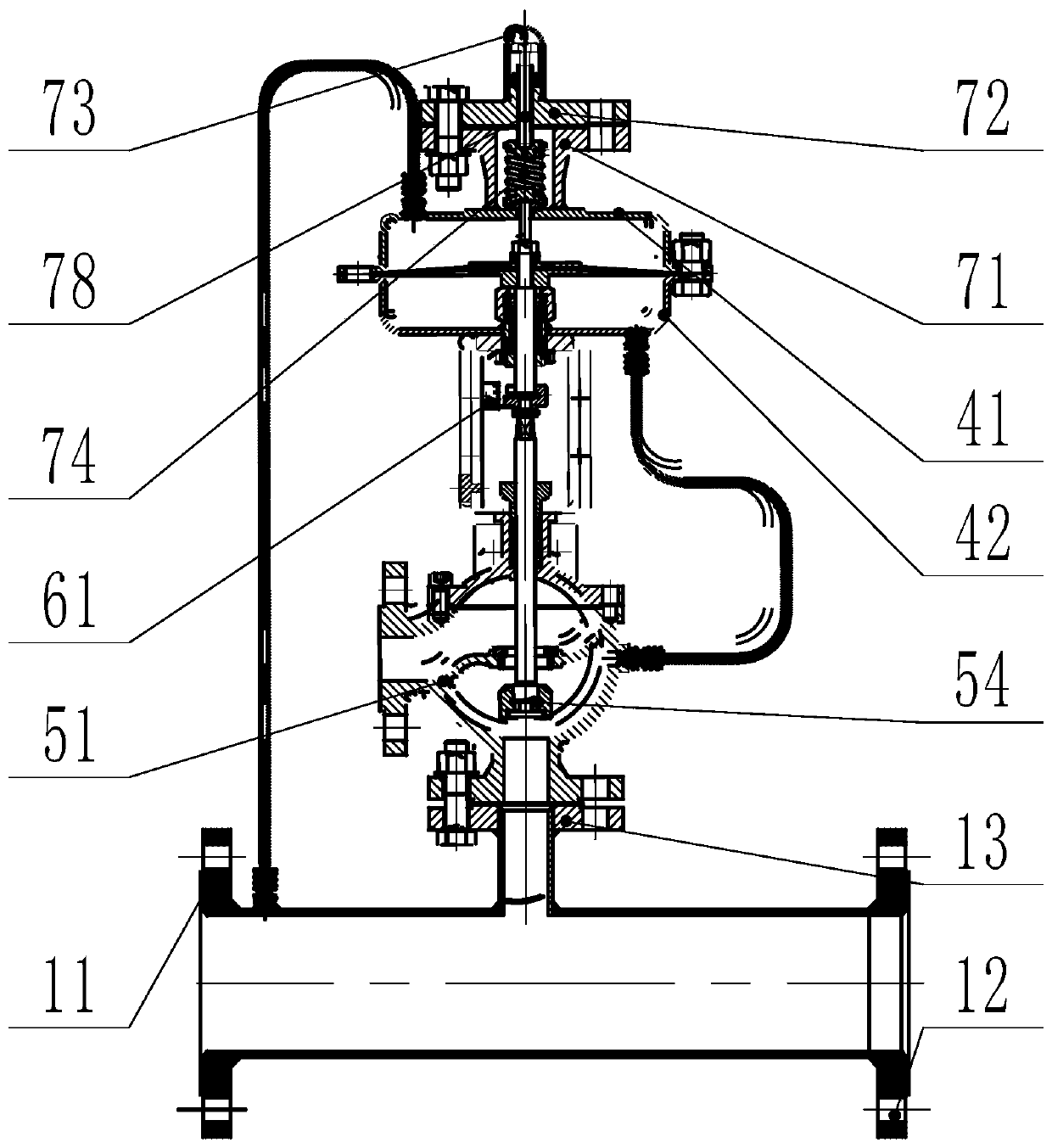

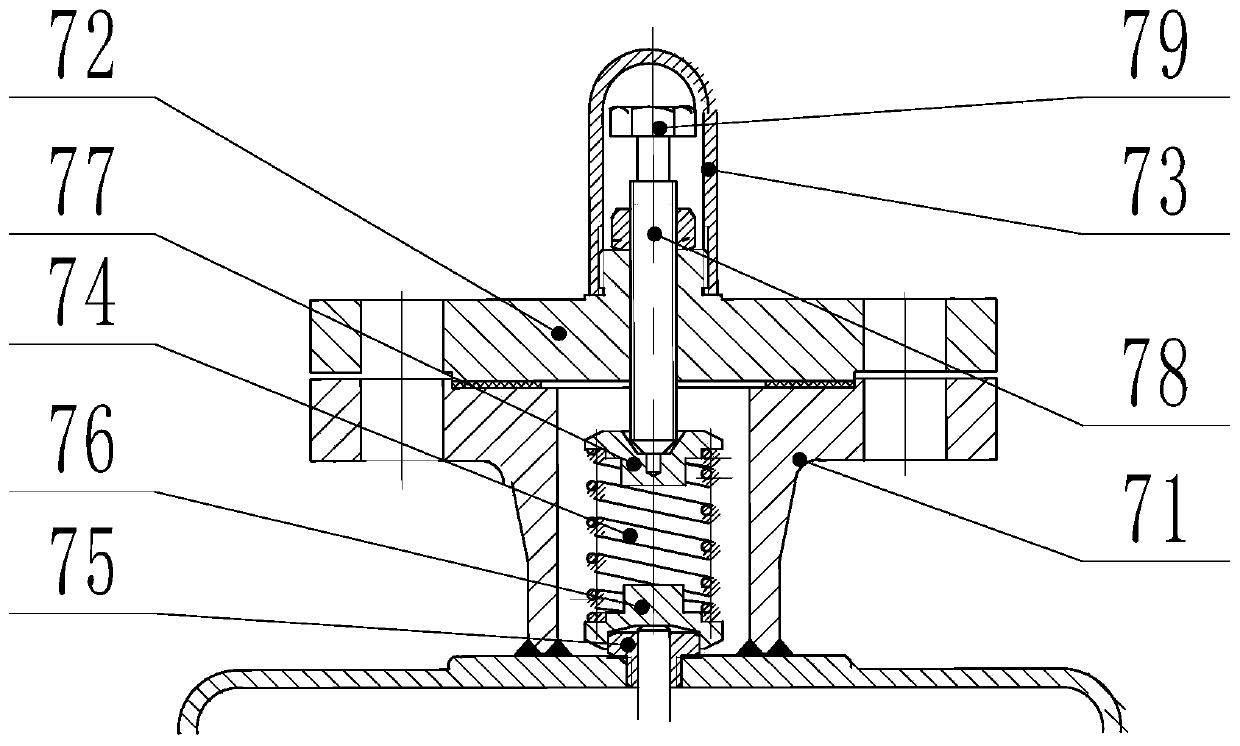

[0038] Such as Figure 1-9 As shown, a mixer capable of adjusting the ratio of foam liquid includes a mixing pipe 1, a first pipe 2, a second pipe 3, a hydraulic film actuator 4, a control valve 5, a support 6 and an upper adjustment module 7; The upper adjustment module 7, the hydraulic film actuator 4, the support 6, the control valve 5 and the mixing pipe 1 are connected in sequence from top to bottom. The two ends of the first pipe 2 are connected to the hydraulic membrane actuator 4 and the mixing pipe 1 respectively, and the two ends of the second pipe 3 are connected to the hydraulic membrane actuator 4 and the control valve 5 respectively.

[0039] The mixing pipe 1 is placed horizontally, one end of the mixing pipe 1 is an inlet for fire-fighting water, and the other end of the mixing pipe 1 is an outlet for the mixed liquid; the upper end of the mixing pipe 1 close to the inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com