Bio-organic fertilizer double-roller extrusion granulator

A bio-organic fertilizer and roller extrusion technology, applied in the direction of die extrusion and granulation, can solve the problems of reducing the density of organic fertilizer particles, hindering the entry of raw materials into grooves, affecting the shape of organic fertilizer particles, etc., to avoid downtime for cleaning, Avoid the difficulty of demolding and ensure the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

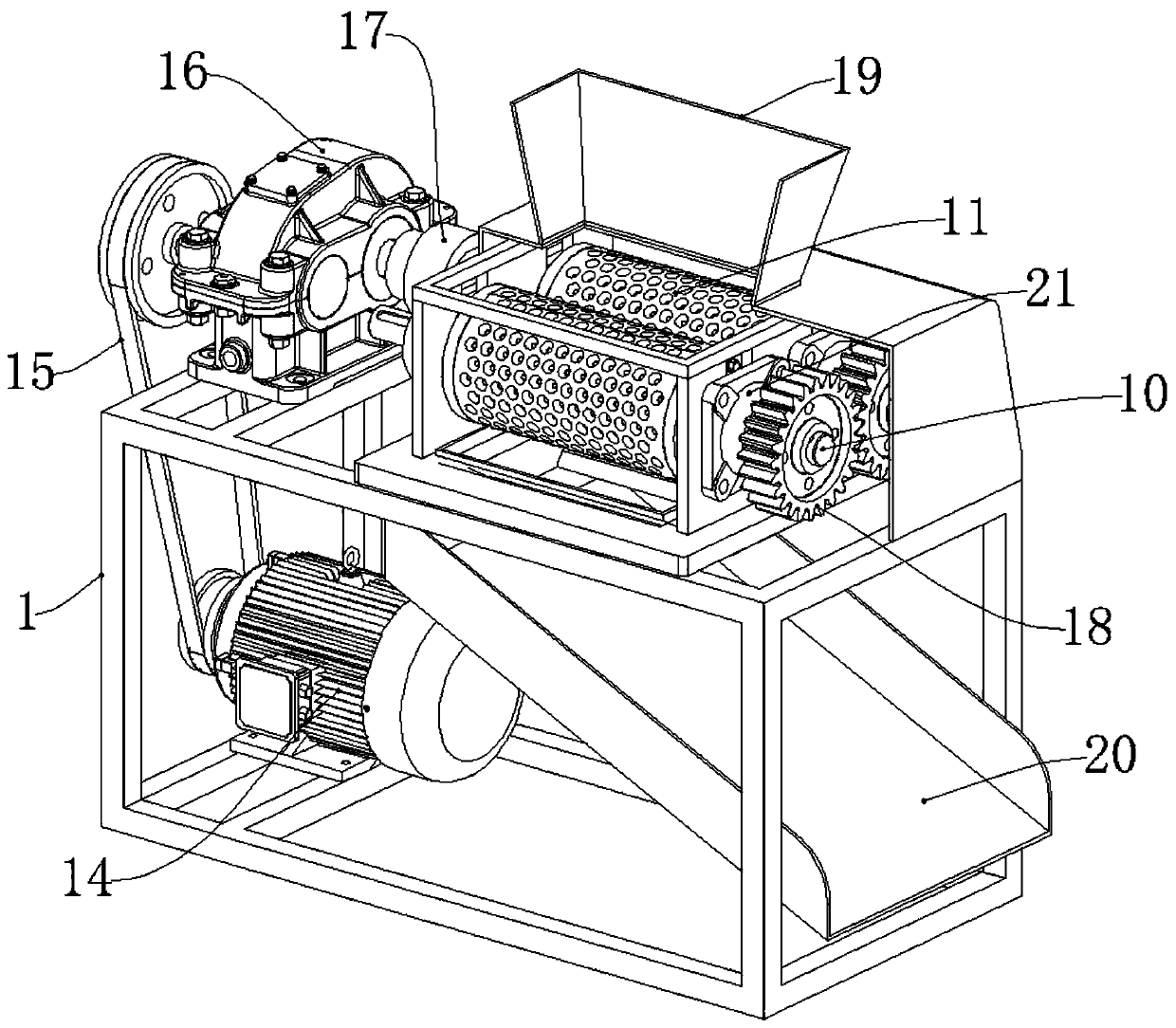

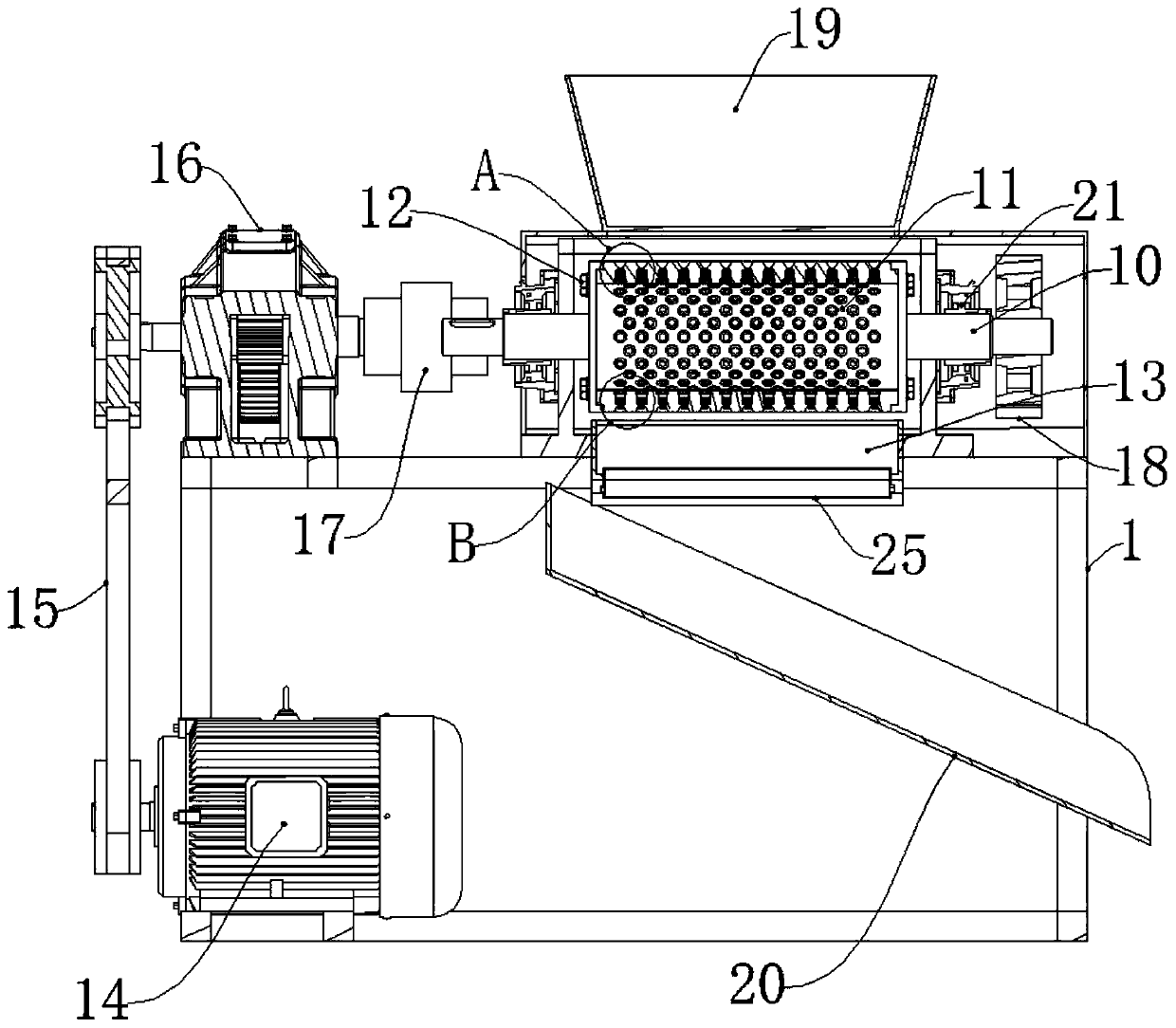

[0027] Such as Figure 1-Figure 8 As shown, a bio-organic fertilizer double-roll extrusion granulator includes a frame 1, a pair of extrusion rollers, a driving mechanism, a demoulding mechanism, a material guide plate 13, a feed hopper 19 and a discharge plate 20.

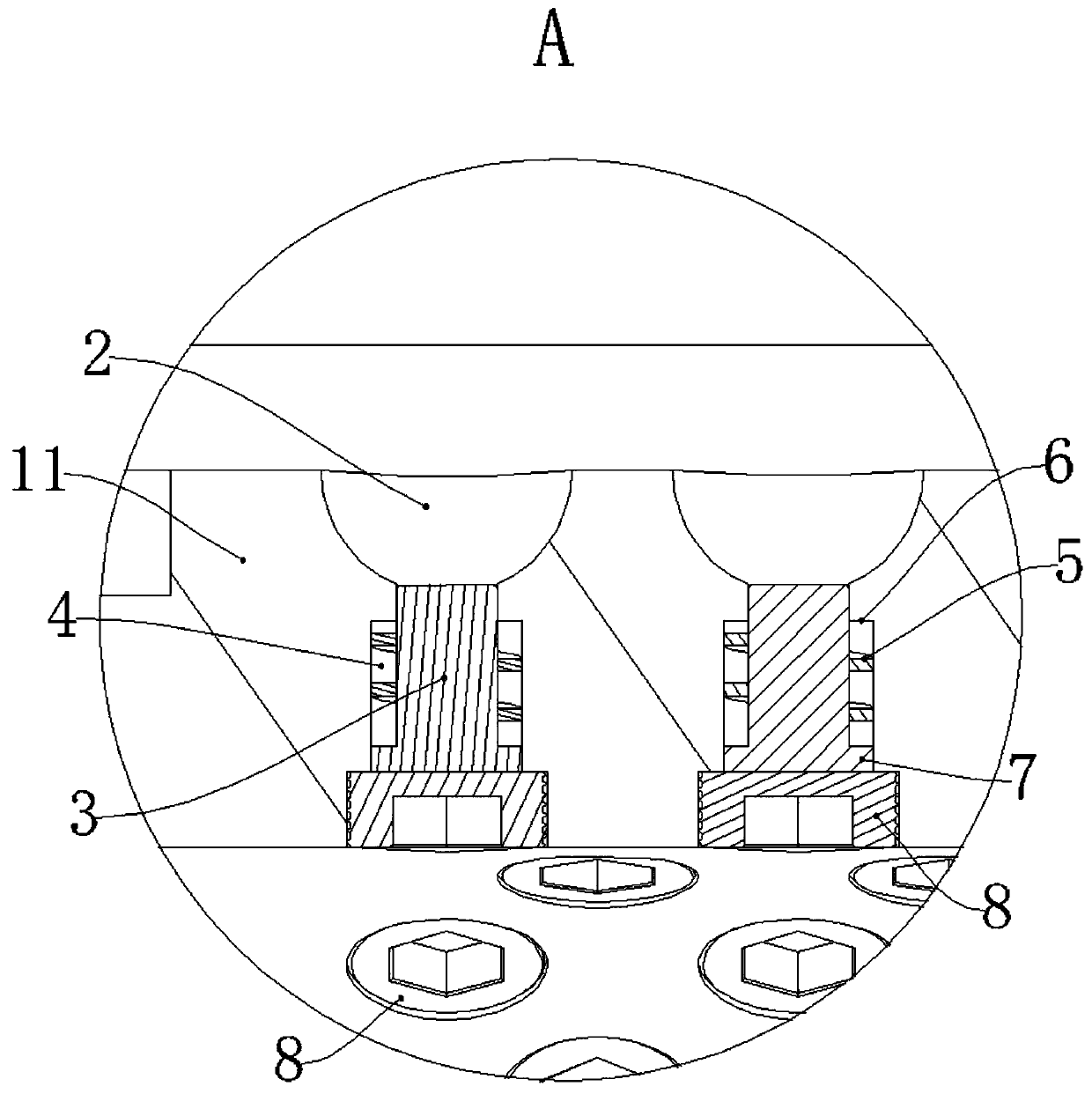

[0028] Such as Figure 8 As shown, the squeeze roller includes a roller, a limit block 8 , an end plate 9 and a mandrel 10 . The roller is composed of two roller petals 11, and the roller petals 11 are semi-cylindrical. Compared with the cylindrical roller, the roller petals 11 are easier to process and facilitate the assembly of the extrusion roller. The outer circular surface of the roller lobe 11 is provided with a hemispherical groove 2, and the roller lobe 11 is provided with a slideway 4 communicating with the hemispherical groove 2, and the slideway 4 is arranged along the radial direction of the roller. The limit block 8 is threadedly installed on the inner circular surface of the roller lobe 11 and bloc...

Embodiment 2

[0035] Such as Figure 8 As shown, different from the first embodiment, the reset mechanism of this embodiment is a reset magnet, which is made of ferromagnetic metal, and the reset magnet and the limit stopper 8 are integrally formed.

[0036] The working principle of the bio-organic fertilizer double-roll extrusion granulator in Example 2: the magnetic force of the reset magnet on the top column 3 makes the top column 3 retract in the slideway 4, the organic fertilizer raw material is placed into the feed hopper 19, and the driving mechanism A pair of extruding rollers are driven to rotate in opposite directions, and the organic fertilizer raw material is extruded into a spherical shape in the hemispherical groove 2. Along with the rotation of extrusion roller, this ejector column 3 rotates to the lower part of extrusion roller, and the active force of electromagnetic sucker 25 to ejector column 3 makes ejector column 3 overcome the magnetic force of reset magnet, and ejecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com