Bamboo tea base processing machine and bamboo green tea preparation method

A processing machine and bamboo tea technology, applied in mechanical equipment, sugarcane mechanical processing, etc., can solve problems such as processing difficulties, achieve the effect of simple and easy preparation method, widely popularized, and avoid waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

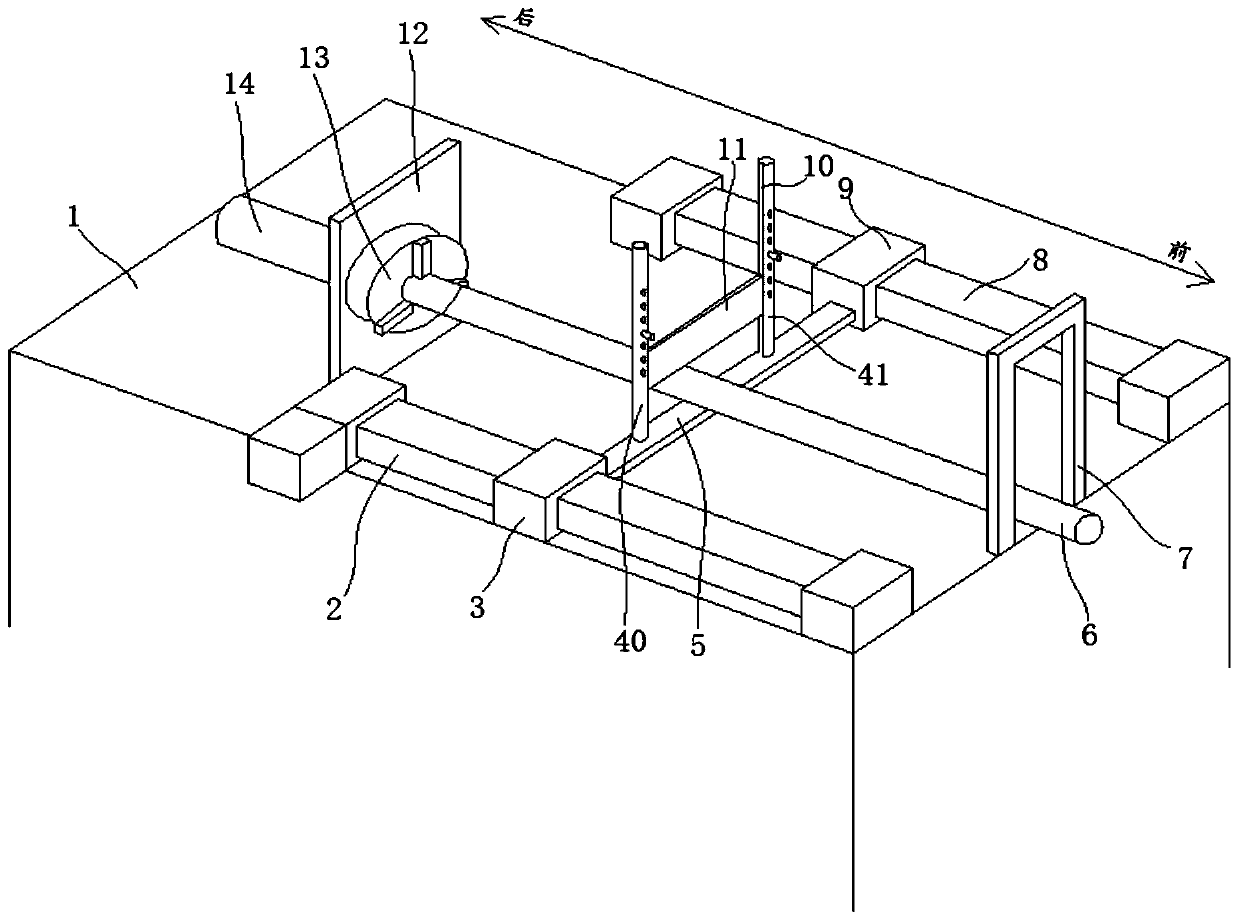

[0046] Such as figure 1 , figure 2 and image 3 As shown, a bamboo tea embryo processing machine includes a processing table 1, a chuck 13, a reciprocating displacement mechanism, a knife rest and a scraper 11;

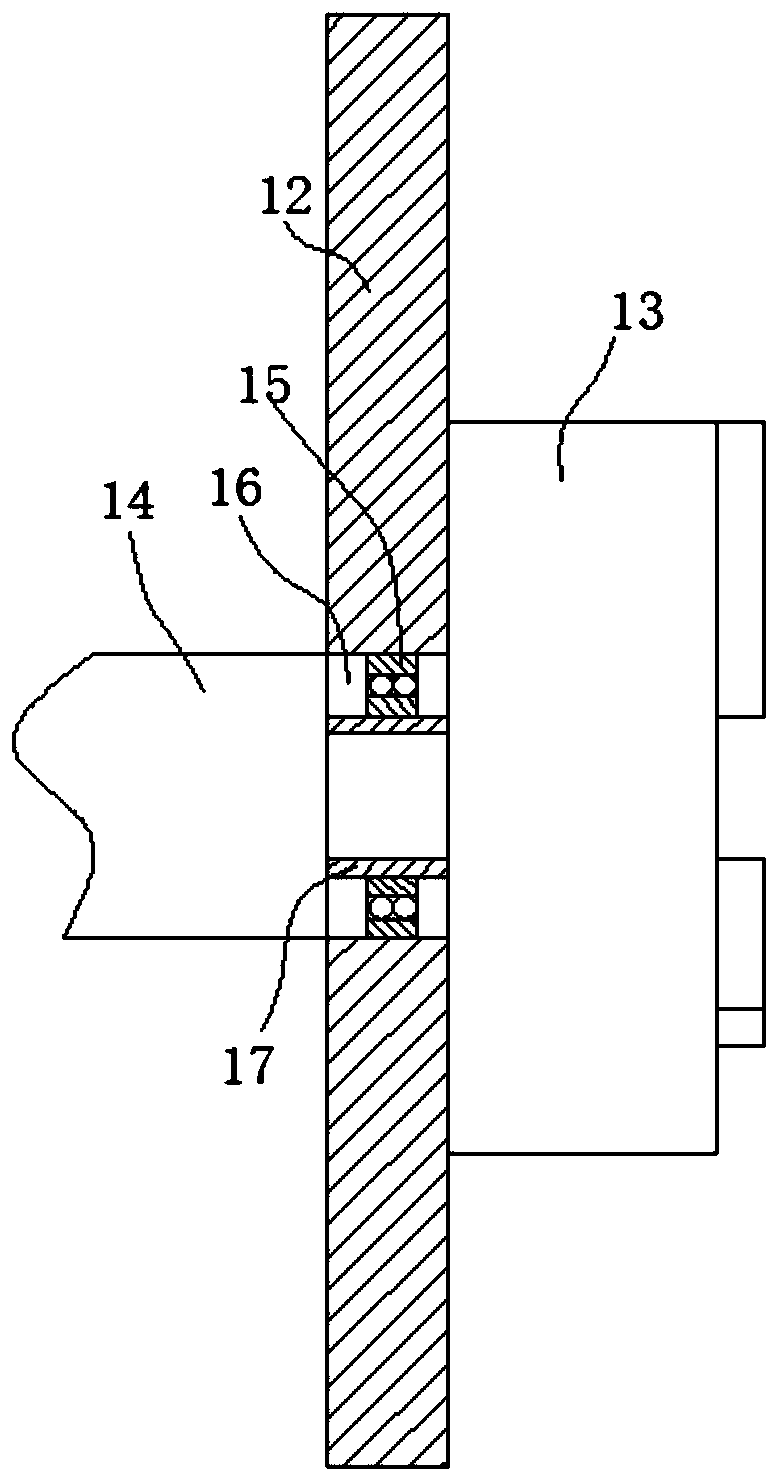

[0047] Chuck 13 is rotatably installed on processing table 1, and is used for clamping bamboo 6, and the position corresponding chuck 13 on processing table 1 is vertically fixedly provided with mounting plate 12, offers mounting hole 16 on mounting plate 12, installs A bearing 15 is coaxially fixed in the hole 16, a mounting pipe 17 is fixed coaxially at the rear end of the middle hole of the chuck 13, and the mounting pipe 17 is fixed on the inner ring of the bearing 15, and the rear end of the mounting hole 16 is coaxially fixedly provided with Discharge guide pipe 14;

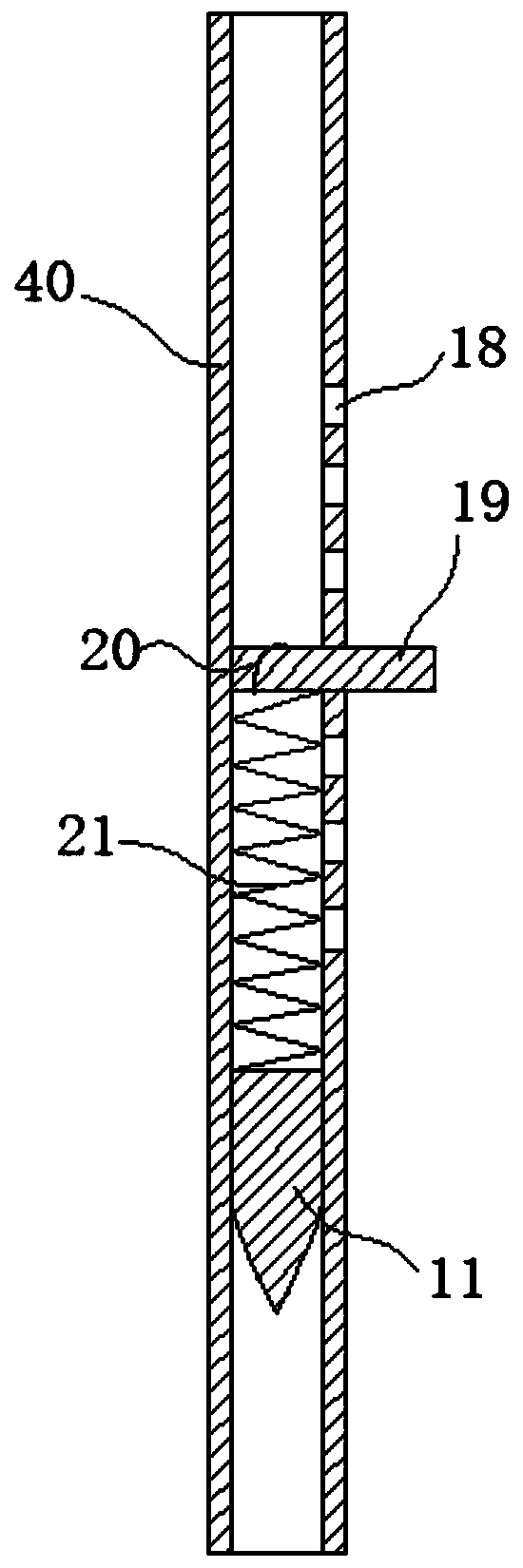

[0048] The knife rest is installed on the reciprocal displacement mechanism, and is positioned at the front of the chuck 13, and the knife rest is pushed forward and backward on the processing ...

Embodiment 2

[0059] The difference between this embodiment and embodiment 1 is:

[0060] Such as Figure 4 As shown, the reciprocating displacement mechanism is composed of linear guide rail B22 and linear guide rail C24, which are respectively installed on both sides of the processing table 1, and extend linearly backward from the front end of the processing table 1; the connecting arm 5 spans the processing Table 1, its two ends are respectively fixedly connected with the sliding seat B23 of the linear guide rail B22 and the sliding seat C25 of the linear guide rail C24. The linear guide rail B22 and the linear guide rail C24 synchronously drive the knife holder to move back and forth on the processing table 1, and then push the scraper 11 to move back and forth on the processing table 1 to peel off the skin of the bamboo 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com