Method for adhesion repair on airplane composite material part by adopting separated double-vacuum-bag hot press molding process

A composite material, thermoforming technology, applied in the field of aircraft maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

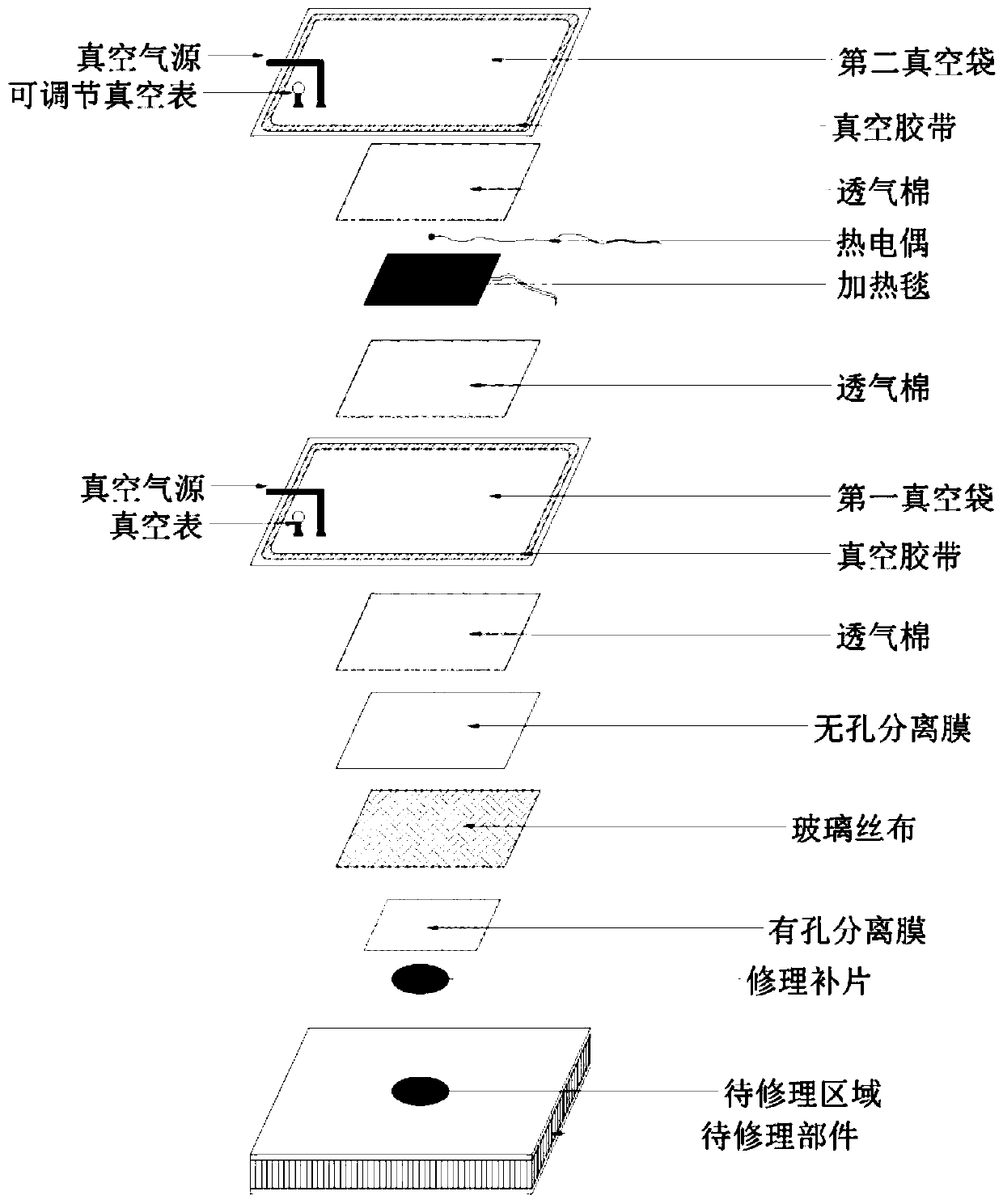

[0052] Such as figure 1 As shown, a method for repairing the skin of the outer cylinder of the reverse thrust translation door of an aircraft using a separate double vacuum bag thermoforming process includes the following steps:

[0053] (1) Determine the bonding area of the skin of the outer cylinder of the reverse thrust translation door of the aircraft as the lower edge of the outer skin, and spread each layer of fiber patches, and the material of the outer skin is a carbon fiber reinforced resin-based composite material;

[0054]Use the laminated patch to pave until there are no wrinkles or cracks between the area to be repaired and the laminated patch of the aircraft composite material part;

[0055] (2) On the patch layer, evenly pave the separation membrane with holes, and each edge of the separation membrane is 1 inch larger than the patch layer;

[0056] The porous separation membrane is a porous high temperature resistant polyethylene film, the same below;

[005...

Embodiment 2

[0069] Such as figure 1 Shown, a kind of method that adopts separate type double-vacuum bag thermocompression forming process to aircraft fan cover is repaired, comprises the following steps:

[0070] (1) Determine the bonding area of the aircraft fan cover, lay out each layer of fiber patches, and the outer skin material is a carbon fiber reinforced resin-based composite material;

[0071] (2) On the patch layer, evenly pave the separation membrane with holes, and each edge of the separation membrane is 1 inch larger than the patch layer;

[0072] (3) Spread glass cloth evenly on the upper layer of the porous separation membrane, and each edge of the glass cloth is 1 inch larger than the porous separation membrane layer;

[0073] (4) Evenly spread the non-porous separation membrane on the upper layer of the glass cloth, and each edge of the non-porous separation film is 1 inch smaller than the glass cloth layer;

[0074] (5) Spread a single layer of breathable cotton even...

Embodiment 3

[0081] Such as figure 1 Shown, a kind of method that adopts separate type double vacuum bag thermocompression forming process to aircraft radome is repaired, comprises the following steps:

[0082] (1) Determine the bonding area of the aircraft radome, lay out each layer of fiber patches, and the outer skin material is a carbon fiber reinforced resin-based composite material;

[0083] (2) On the patch layer, evenly pave the separation membrane with holes, and each edge of the separation membrane is 1 inch larger than the patch layer;

[0084] (3) Spread glass cloth evenly on the upper layer of the porous separation membrane, and each edge of the glass cloth is 1 inch larger than the porous separation membrane layer;

[0085] (4) Evenly spread the non-porous separation membrane on the upper layer of the glass cloth, and each edge of the non-porous separation film is 1 inch smaller than the glass cloth layer;

[0086] (5) Spread a single layer of breathable cotton evenly on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com