Cloisonne parquet manufacturing method

A production method, the technology of cloisonné, applied in the field of decorative materials, can solve the problems of inconvenient installation of inlays and difficult processing of inlay grooves, etc., and achieve the effect of ensuring flatness, preventing edge warping, and ensuring appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

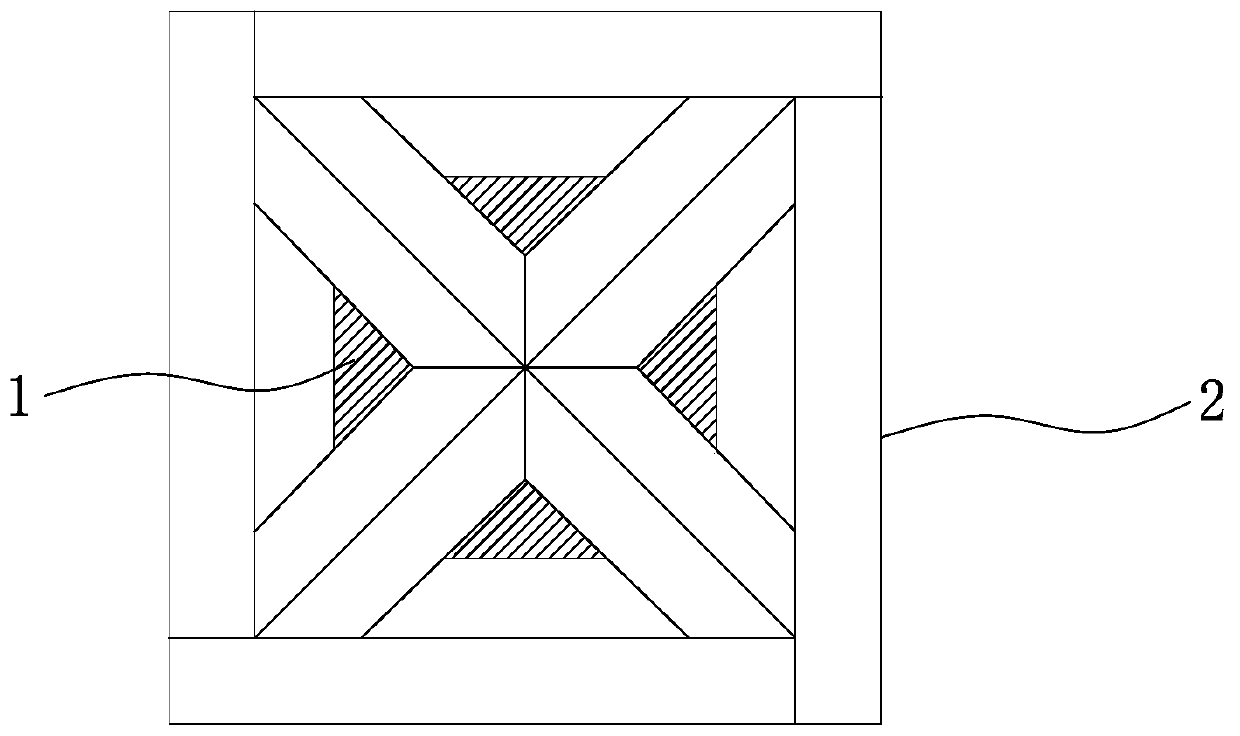

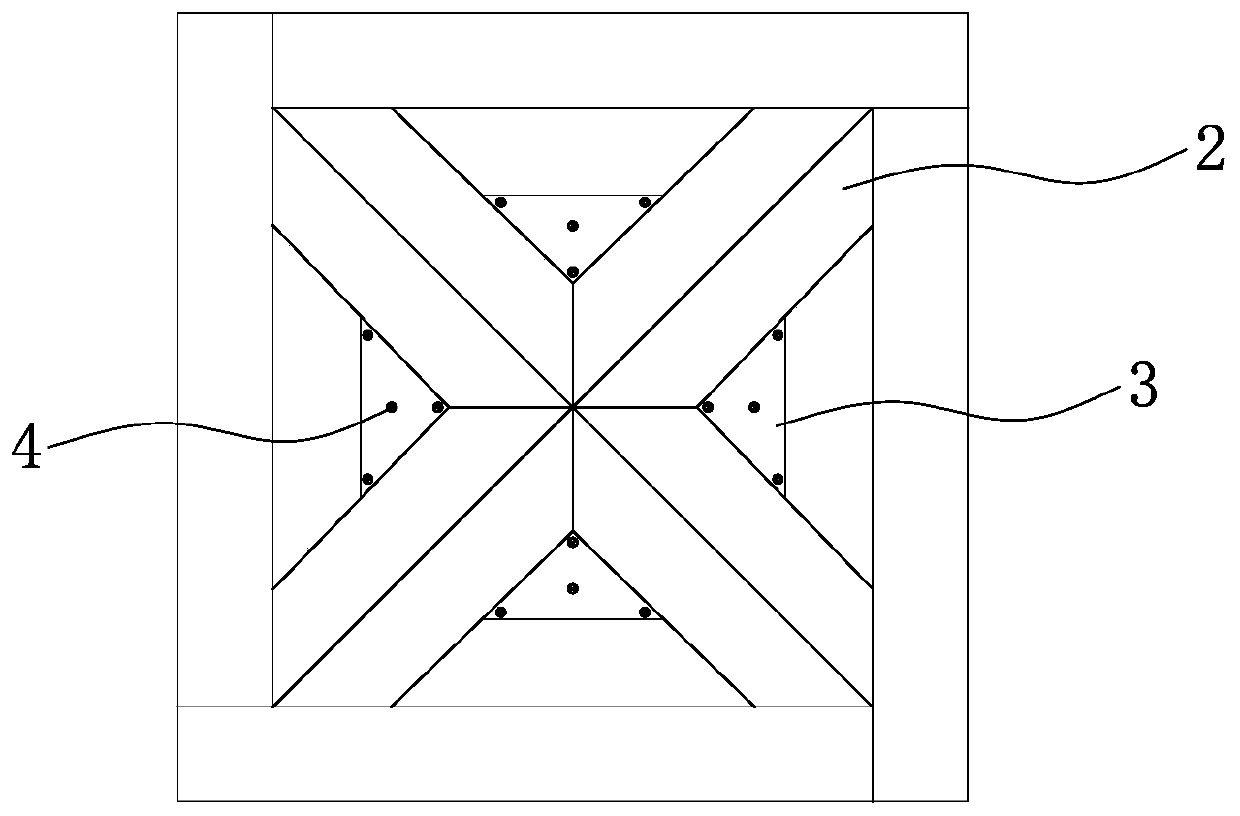

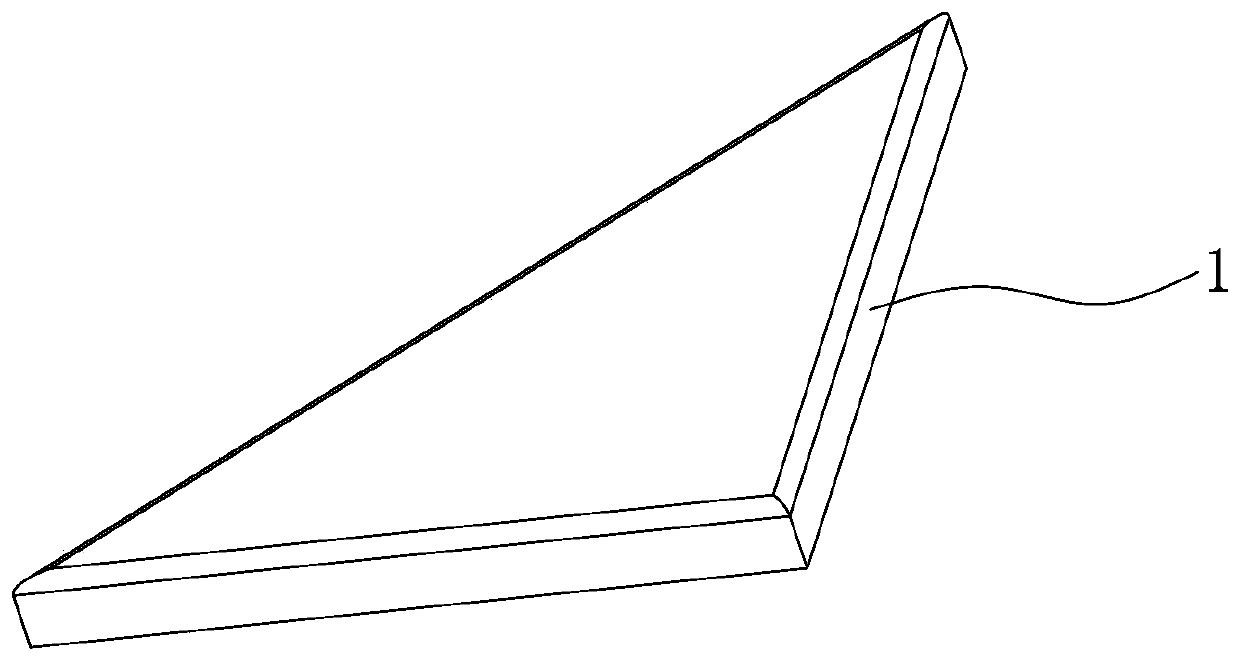

[0045] The present embodiment provides a kind of cloisonné mosaic board manufacturing method, combines figure 1 with figure 2 shown, including the following steps:

[0046] Step 1: Select the content of the pattern, make design drawings according to the content of the pattern, and select a suitable wood material. The wood material can be commonly used wood, such as pine, oak, beech or elm;

[0047] Step 2: Make the cloisonné insert 1 and the mosaic board 2 according to the design drawings. A groove 3 is provided on the surface of the mosaic board 2. The depth of the groove 3 is 4 mm, and the thickness of the cloisonne insert 1 is 3 mm. 3, the depth of the groove 3 is slightly greater than the thickness of the cloisonné insert 1, so that after injecting the adhesive to realize the bonding and embedding of the cloisonné insert 1, the upper surface of the cloisonné insert 1 can be roughly flush with the mosaic board 2, which is relatively Good guarantee of flatness;

[0048] ...

Embodiment 2

[0067] The present embodiment provides a kind of cloisonné mosaic board manufacturing method, combines figure 1 with figure 2 shown, including the following steps:

[0068] Step 1: Select the pattern content, make design drawings according to the pattern content, and select the appropriate wood material;

[0069] Step 2: Prepare the cloisonné insert 1 and the mosaic board 2 according to the design drawings, the surface of the mosaic board 2 is provided with a groove 3, the depth of the groove 3 is 3.5mm, and the thickness of the cloisonne insert 1 is 3mm;

[0070] Step 3: Color the surface of the board, adjust the surface color effect until the color is uniform;

[0071] Step 4: Inject adhesive into the groove 3, and place several feet 4 to the inside of the groove 3 along the edge of the groove 3. The thickness of the feet 4 is 0.5mm, which is the thickness of the groove 3 after the adhesive is injected. 0.55mm;

[0072] Step 5: Insert the cloisonné insert 1. The cloison...

Embodiment 3

[0074] The present embodiment provides a kind of cloisonné mosaic board manufacturing method, combines figure 1 with figure 2 shown, including the following steps:

[0075] Step 1: Select the pattern content, make design drawings according to the pattern content, and select the appropriate wood material;

[0076] Step 2: Prepare the cloisonné insert 1 and the mosaic board 2 according to the design drawings, the surface of the mosaic board 2 is provided with a groove 3, the depth of the groove 3 is 4.5mm, and the thickness of the cloisonne insert 1 is 3mm;

[0077] Step 3: Color the surface of the board, adjust the surface color effect until the color is uniform;

[0078] Step 4: Inject adhesive into the groove 3, and place several feet 4 to the inside of the groove 3 along the edge of the groove 3. The thickness of the feet 4 is 1.5 mm, which is the thickness of the groove 3 after the adhesive is injected. 1.575mm;

[0079] Step 5: Embed the cloisonné insert 1. The cloiso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com