Water system

A waterway and pure water technology, applied in multi-stage water treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of complex filter element connection structure, unfavorable product promotion, unfavorable product maintenance, etc., and achieve disassembly and assembly. Easy, easy to maintain and repair, simple effect of mold forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

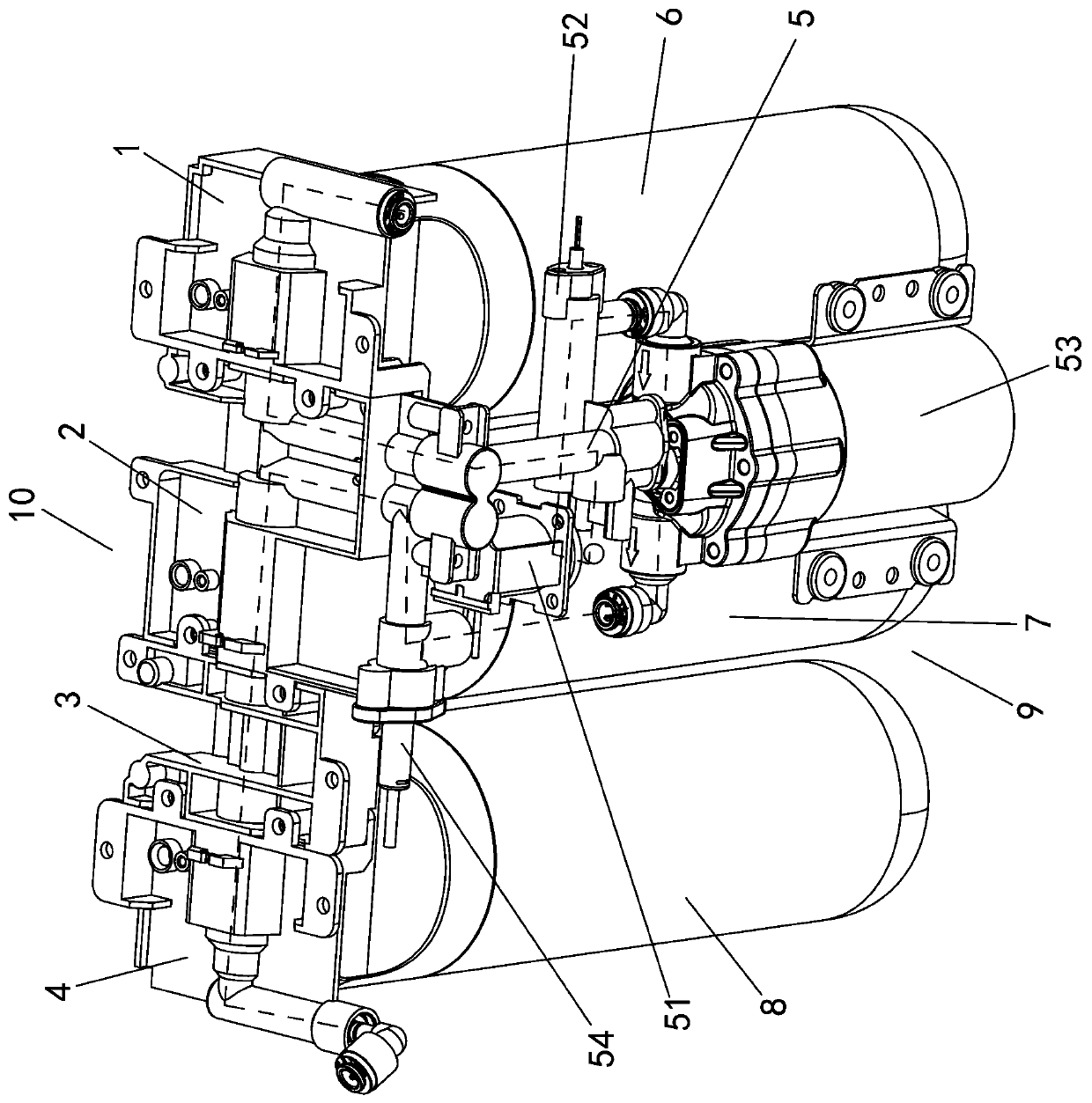

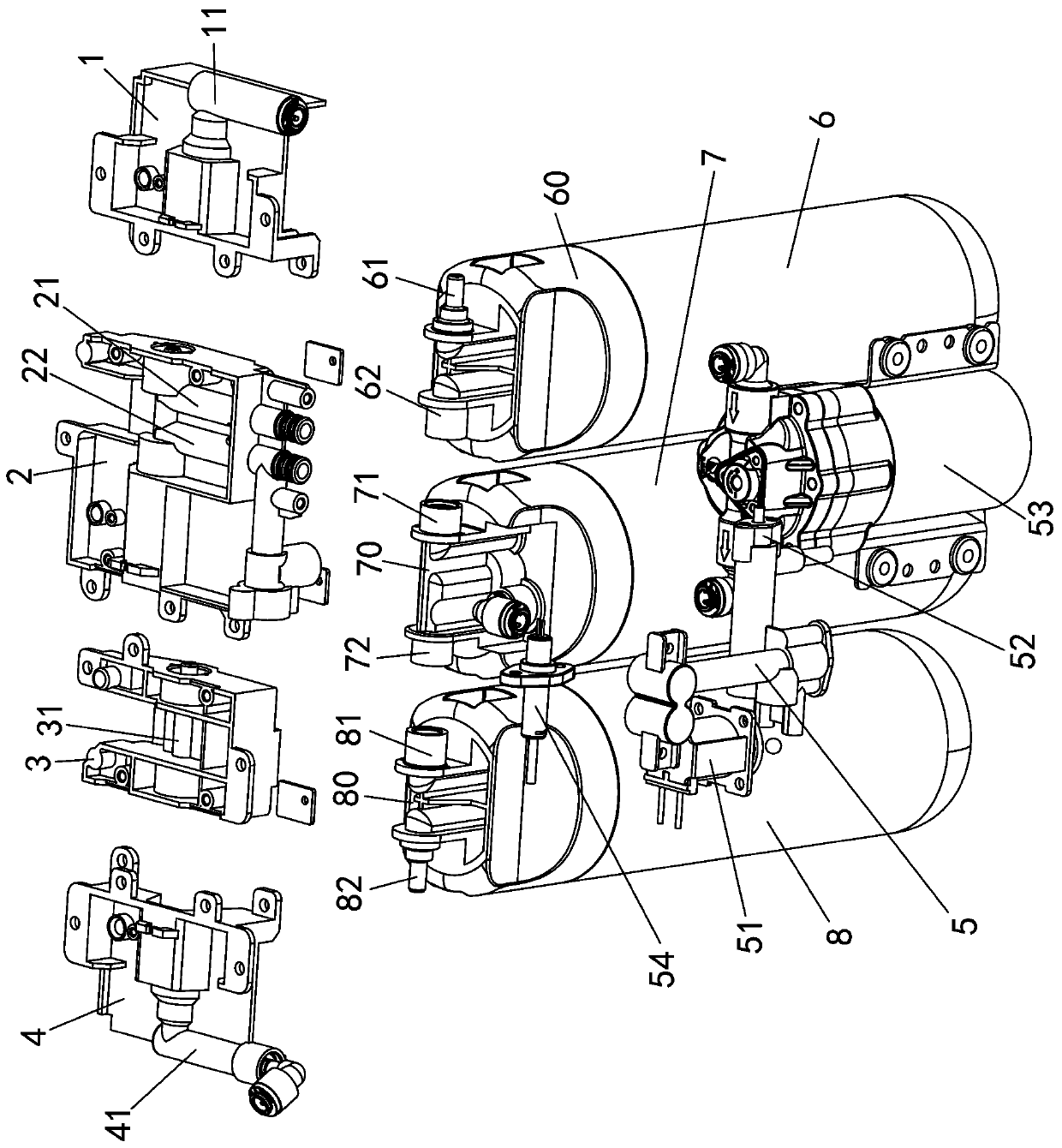

[0024] Embodiment one, see Figure 1 to Figure 2 As shown, a water system includes a waterway and a filter element assembly. The waterway is a modular spliced waterway 10. The spliced waterway 10 includes a first module 1, a second module 2, a third module 3, a fourth module 4 and a first module. Five modules 5, each module is a separate waterway board, and each module is provided with a waterway pipeline, the filter element assembly 9 includes a pre-filter element 6, an RO filter element 7 and a post-filter element 8, the first module 1 and The second module 2 is fixedly connected and clamped to fix the pre-filter element 6. The pre-filter element 6 communicates with the water pipeline of the first module 1 and the second module 2, and the water pipeline of the fifth module 5 communicates with the water pipeline of the second module 2. In the pipeline, the second module 2 and the third module 3 are fixedly connected and clamped to fix the RO filter element 7. The RO filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com