Anti-counterfeiting glass ceramic composite material and manufacturing method thereof

A technology of glass ceramics and composite materials, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of not showing obvious up-conversion luminescence changes, deciphering and counterfeiting of materials, and prone to large batches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

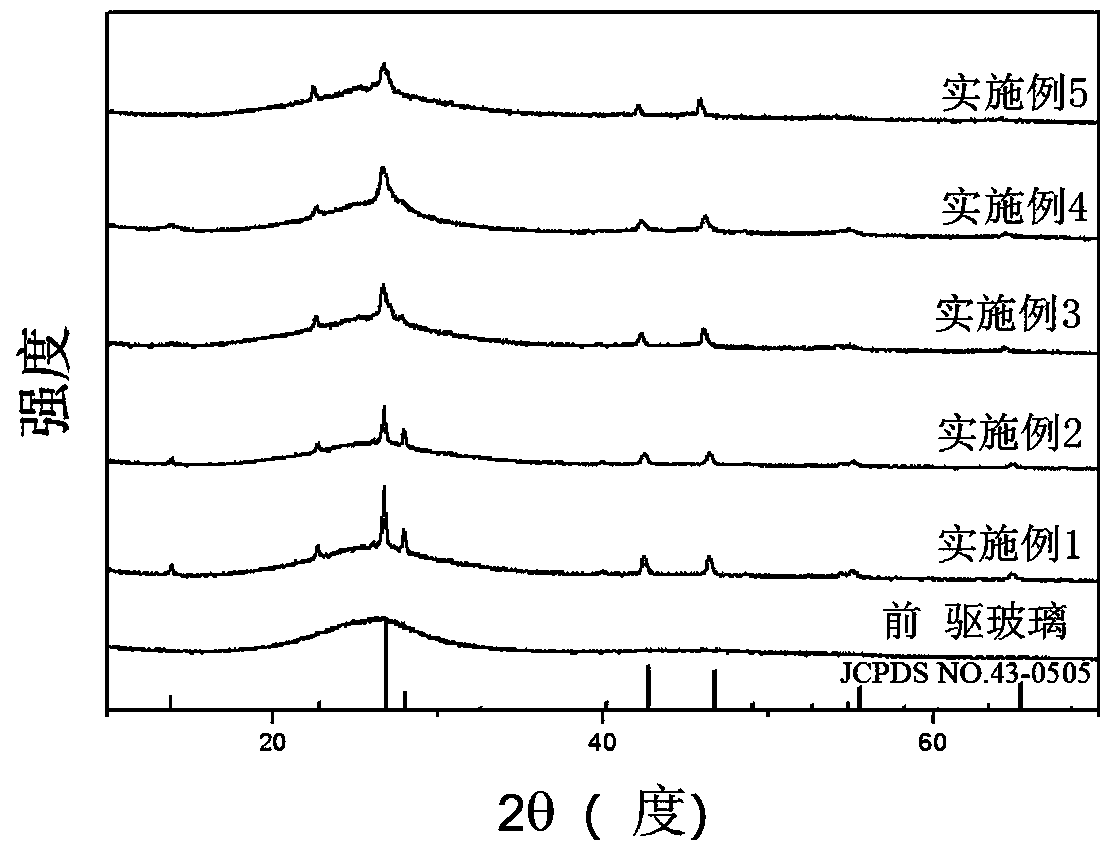

Embodiment 1

[0038] A preparation method of anti-counterfeiting material, comprising the following steps:

[0039] (1) Preparation of mixture Ⅰ: Weigh SiO in a specific molar ratio 2 , Al 2 o 3 , Cs 2 CO 3 , CsF, YbF 3 and ErF 3 , and the corresponding molar ratios are 49:10:12:15:13.7 and 0.3, respectively, and put them in a ceramic crucible after grinding fully;

[0040] (2) Raise the temperature of the high-temperature box furnace to 1500°C;

[0041] (3) Put the crucible containing the mixture I into the high-temperature box furnace of step (2) and fully sinter for 45 minutes after adding a crucible cover;

[0042] (4) Take out the sintered molten liquid directly from the high-temperature box furnace with crucible tongs and pour it on the copper mold, and quickly cover the copper mold cover to quench to form the precursor glass;

[0043] (5) Put the precursor glass into a muffle furnace and raise the temperature to 850° C. and hold it for 2 hours for heat treatment to form glass...

Embodiment 2

[0045] A preparation method of anti-counterfeiting material, comprising the following steps:

[0046] (1) Preparation of mixture Ⅰ: Weigh SiO in a specific molar ratio 2 , Al 2 o 3 , Cs 2 CO 3 , CsF, YbF 3 , ErF3 , the molar ratio is 63:7:9:10:10.7:0.3, after being fully ground, put it in a ceramic crucible for later use;

[0047] (2) Raise the temperature of the high-temperature box furnace to 1550°C;

[0048] (3) Put the crucible with the mixture I into the high-temperature box furnace and fully sinter it for 40 minutes after adding the crucible cover;

[0049] (4) Take out the sintered molten liquid directly from the high-temperature box furnace with crucible tongs and pour it on the copper mold, and quickly cover the copper mold cover to quench to form the precursor glass;

[0050] (5) Put the precursor glass into a muffle furnace and raise the temperature to 750° C. and hold it for 2 hours for heat treatment to form glass ceramics, and obtain the anti-counterfeitin...

Embodiment 3

[0052] A preparation method of anti-counterfeiting material, comprising the following steps:

[0053] (1) Preparation of mixture Ⅰ: Weigh SiO in a specific molar ratio 2 , Al 2 o 3 , Cs 2 CO 3 , CsF, YbF 3 , ErF 3 , the molar ratio is 71:6:8:9:5.7:0.3, after being fully ground, put it in a ceramic crucible for later use;

[0054] (2) Raise the temperature of the high-temperature box furnace to 1550°C;

[0055] (3) Put the crucible with the mixture I into the high-temperature box furnace and fully sinter it for 25 minutes after adding the crucible cover;

[0056] (4) Take out the sintered molten liquid directly from the high-temperature box furnace with crucible tongs and pour it on the copper mold, and quickly cover the copper mold cover to quench to form the precursor glass;

[0057] (5) Put the precursor glass into a muffle furnace and raise the temperature to 950° C. and hold it for 2 hours for heat treatment to form glass ceramics, and obtain the anti-counterfeitin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com