A kind of preparation method of anti-counterfeiting glass-ceramic composite material

A composite material and glass-ceramic technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of deciphering and counterfeiting materials, prone to large quantities, and not having high photothermal effect embedded in glass-ceramic anti-counterfeiting materials. The effect of anti-counterfeiting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

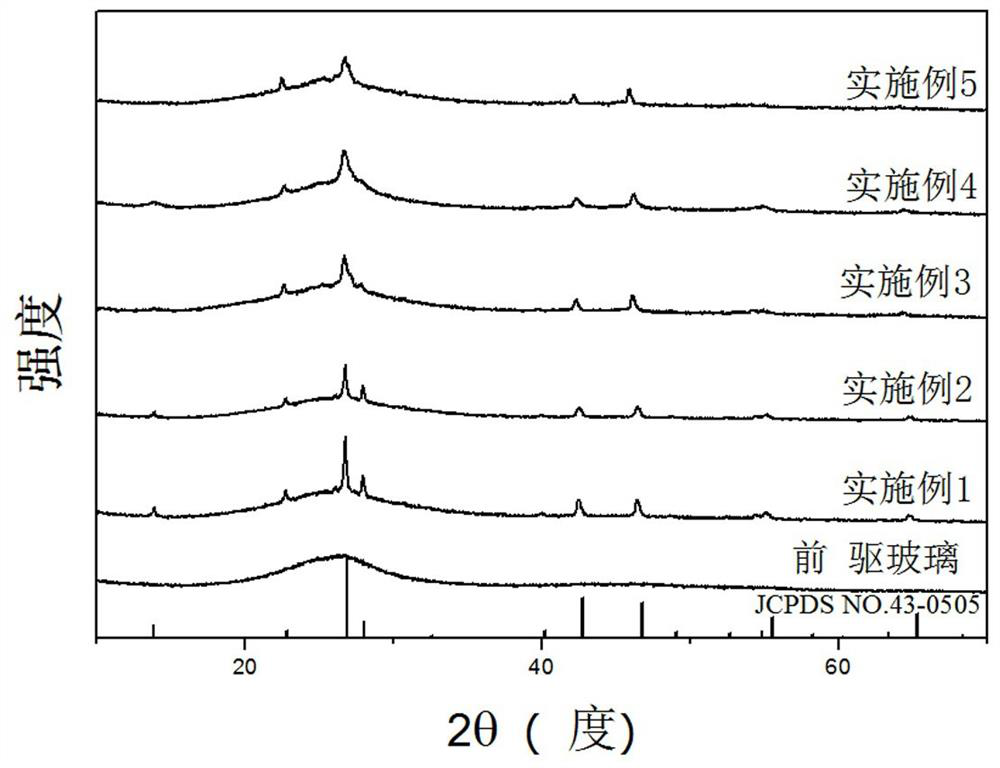

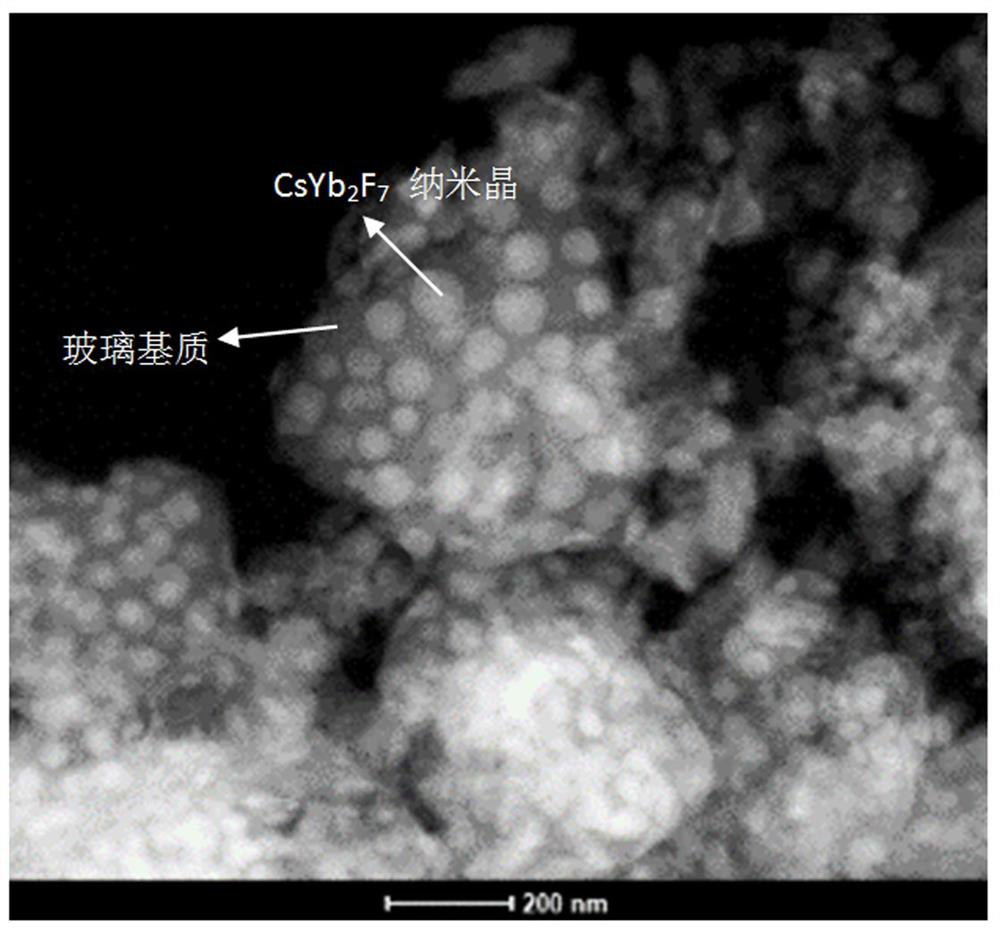

Embodiment 1

[0038] A preparation method of anti-counterfeiting material, comprising the following steps:

[0039] (1) Preparation of mixture Ⅰ: Weigh SiO in a specific molar ratio 2 , Al 2 o 3 , Cs 2 CO 3 , CsF, YbF 3 and ErF 3 , and the corresponding molar ratios are 49:10:12:15:13.7 and 0.3, respectively, and put them in a ceramic crucible after grinding fully;

[0040] (2) Raise the temperature of the high-temperature box furnace to 1500°C;

[0041] (3) Put the crucible containing the mixture I into the high-temperature box furnace of step (2) and fully sinter for 45 minutes after adding a crucible cover;

[0042] (4) Take out the sintered molten liquid directly from the high-temperature box furnace with crucible tongs and pour it on the copper mold, and quickly cover the copper mold cover to quench to form the precursor glass;

[0043] (5) Put the precursor glass into a muffle furnace and raise the temperature to 850° C. and hold it for 2 hours for heat treatment to form glass...

Embodiment 2

[0045] A preparation method of anti-counterfeiting material, comprising the following steps:

[0046] (1) Preparation of mixture Ⅰ: Weigh SiO in a specific molar ratio 2 , Al 2 o 3 , Cs 2 CO 3 , CsF, YbF 3 , ErF3 , the molar ratio is 63:7:9:10:10.7:0.3, after being fully ground, put it in a ceramic crucible for later use;

[0047] (2) Raise the temperature of the high-temperature box furnace to 1550°C;

[0048] (3) Put the crucible with the mixture I into the high-temperature box furnace and fully sinter it for 40 minutes after adding the crucible cover;

[0049] (4) Take out the sintered molten liquid directly from the high-temperature box furnace with crucible tongs and pour it on the copper mold, and quickly cover the copper mold cover to quench to form the precursor glass;

[0050] (5) Put the precursor glass into a muffle furnace and raise the temperature to 750° C. and hold it for 2 hours for heat treatment to form glass ceramics, and obtain the anti-counterfeitin...

Embodiment 3

[0052] A preparation method of anti-counterfeiting material, comprising the following steps:

[0053] (1) Preparation of mixture Ⅰ: Weigh SiO in a specific molar ratio 2 , Al 2 o 3 , Cs 2 CO 3 , CsF, YbF 3 , ErF 3 , the molar ratio is 71:6:8:9:5.7:0.3, after being fully ground, put it in a ceramic crucible for later use;

[0054] (2) Raise the temperature of the high-temperature box furnace to 1550°C;

[0055] (3) Put the crucible with the mixture I into the high-temperature box furnace and fully sinter it for 25 minutes after adding the crucible cover;

[0056] (4) Take out the sintered molten liquid directly from the high-temperature box furnace with crucible tongs and pour it on the copper mold, and quickly cover the copper mold cover to quench to form the precursor glass;

[0057] (5) Put the precursor glass into a muffle furnace and raise the temperature to 950° C. and hold it for 2 hours for heat treatment to form glass ceramics, and obtain the anti-counterfeitin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com