Warp stop control box with segmented display function

A technology for controlling boxes and warps, which is applied in textiles, textiles, papermaking, looms, etc. It can solve problems such as poor contact, the inability of the car operator to find out the broken warp yarns in the first place, and affecting the quality of finished products and the working efficiency of looms. To achieve the effect of compact circuit structure and good electrical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but the description of the embodiments is not a limitation on the technical solution, and any changes in form but not in substance according to the concept of the present invention should be regarded as the protection scope of the present invention.

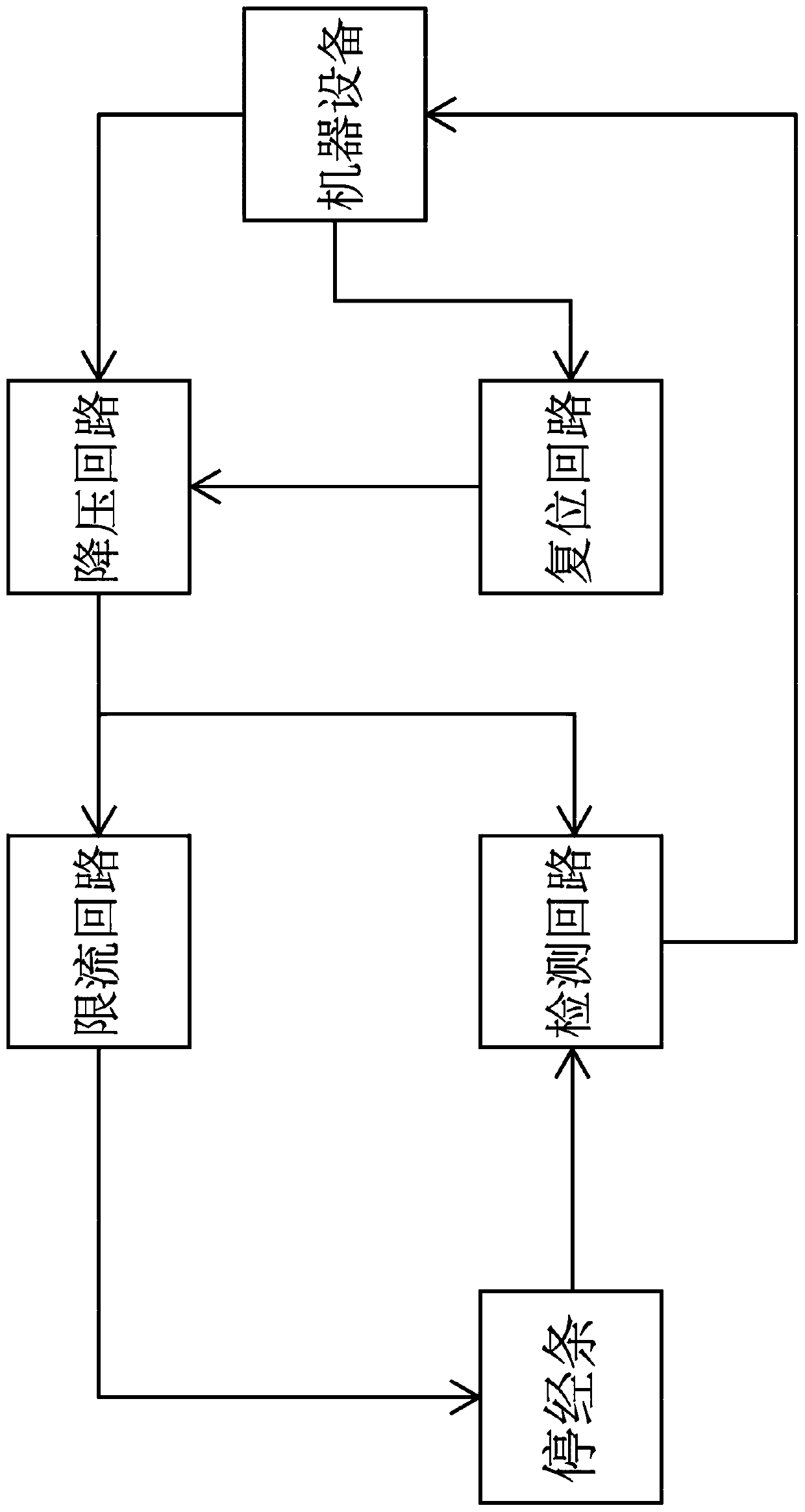

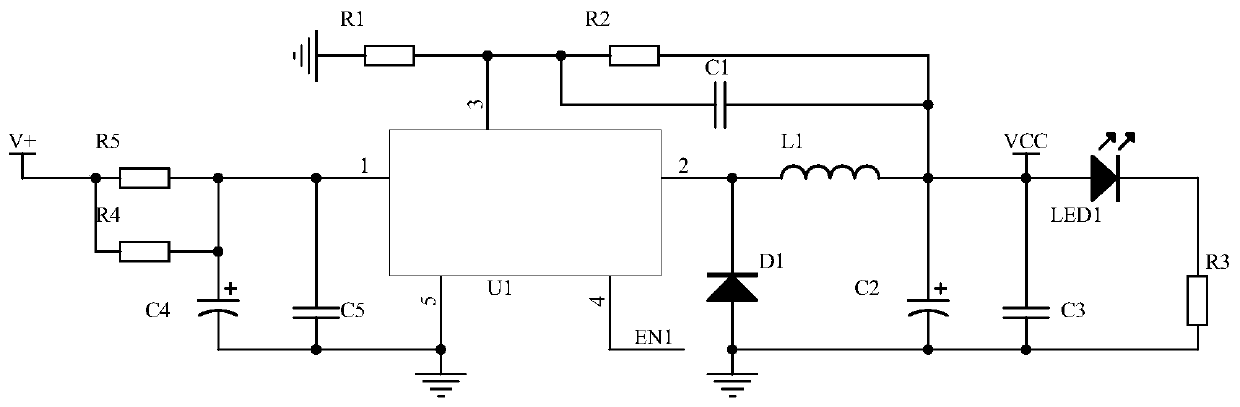

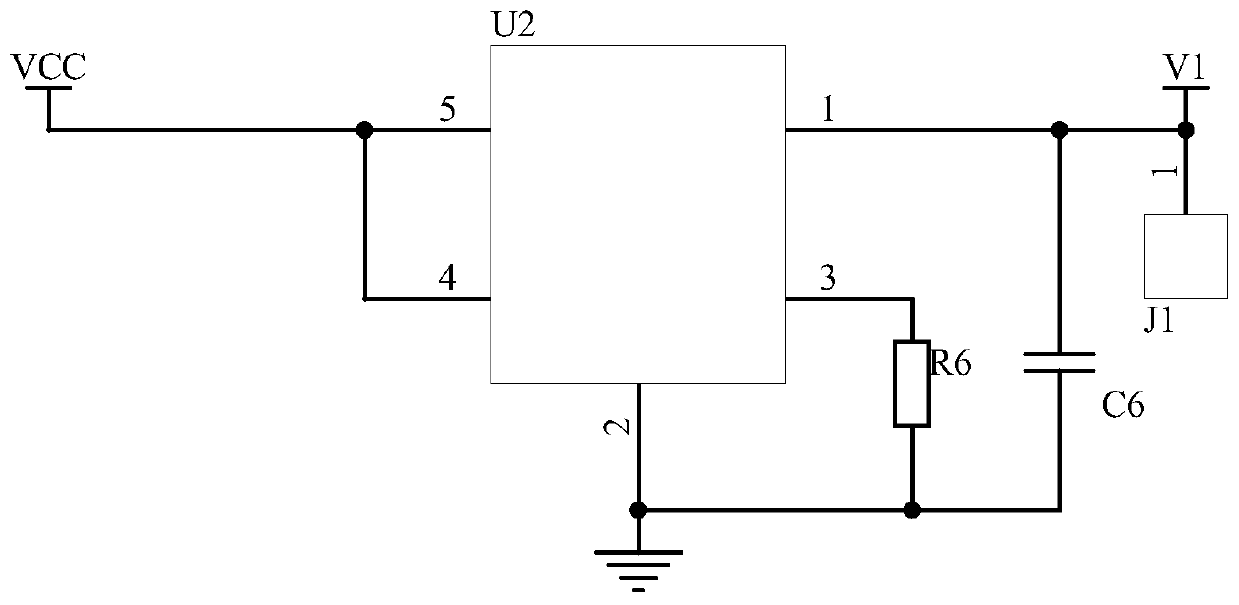

[0019] see figure 1, a segmented stop display control box includes a detection circuit, a current limiting circuit, a step-down circuit and a reset circuit. The step-down circuit is connected to the machine equipment to obtain power supply from the machine equipment. The machine equipment here is a loom as an example. The step-down circuit is connected with the current-limiting circuit and the detection circuit respectively to provide the reduced power supply for both, and the current-limiting circuit is connected to the warp-stop bar, and is used to limit the current of the stepped-down pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com