Existing line protective shed frame, protective shred and mounting method

An installation method and technology for protective sheds, which are applied in special buildings, small buildings, building types, etc., can solve the problems of unusable cranes and high investment in protective scaffolding infrastructure, reduce hanging requirements, and ensure effective utilization. rate, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

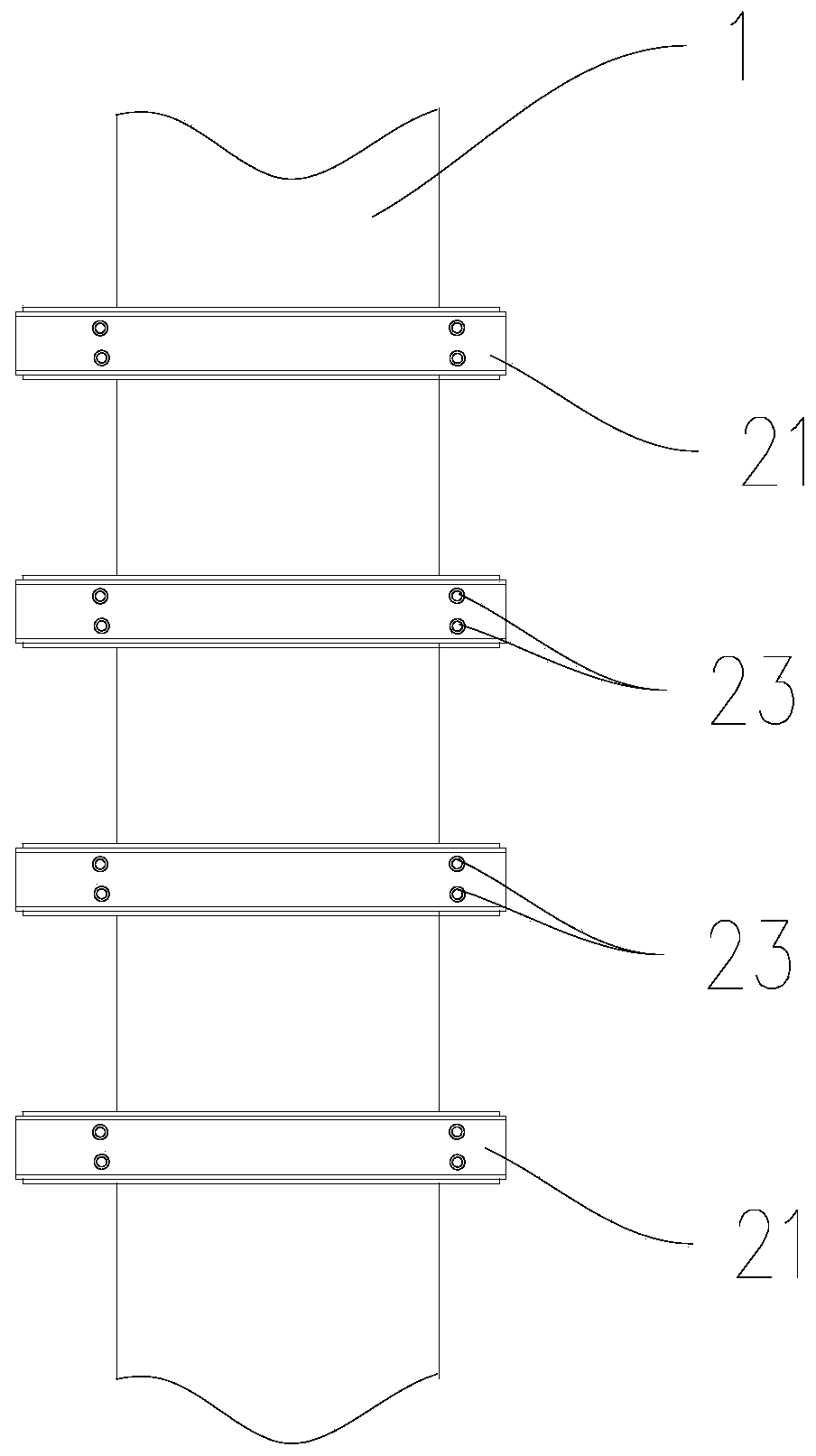

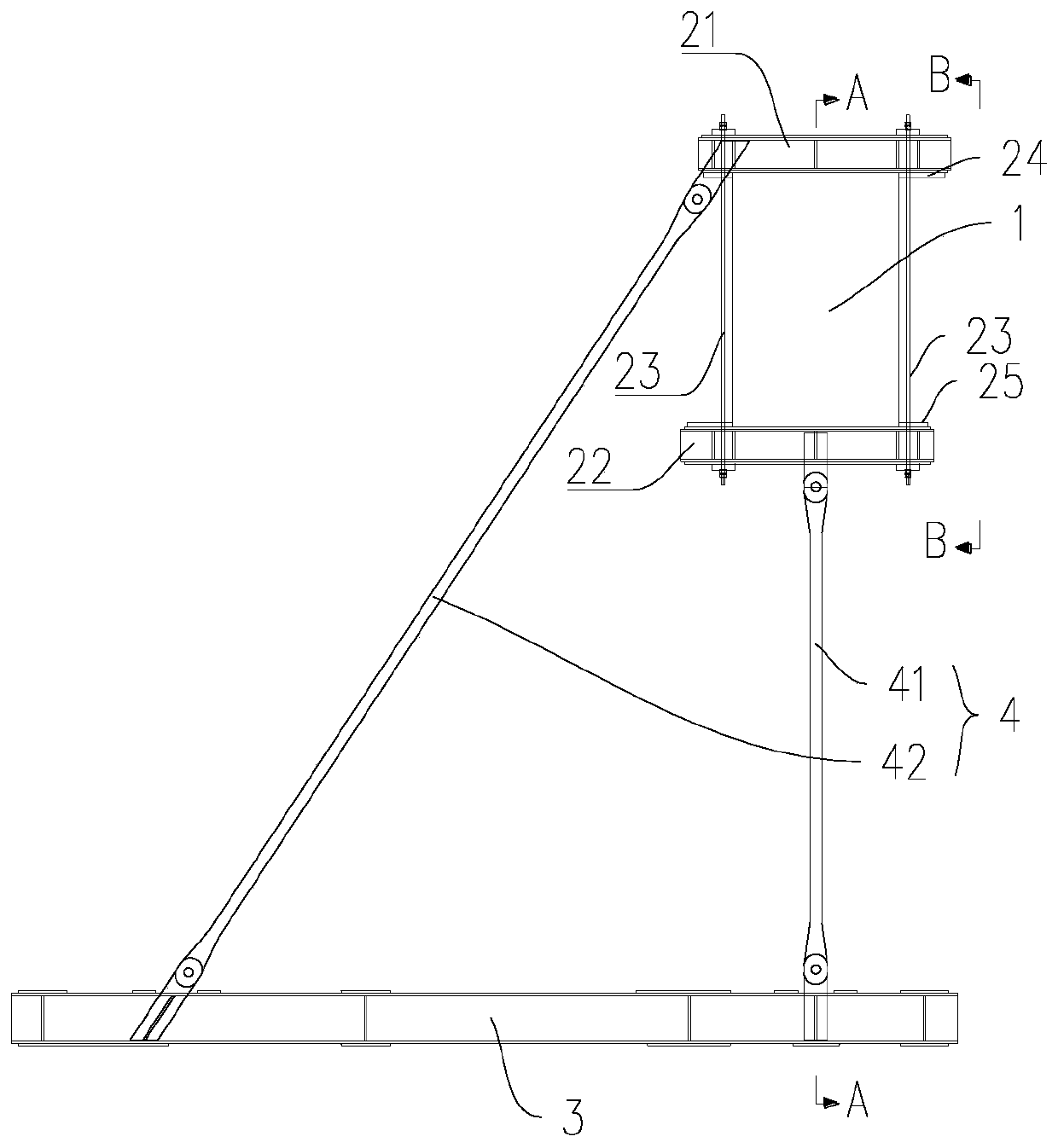

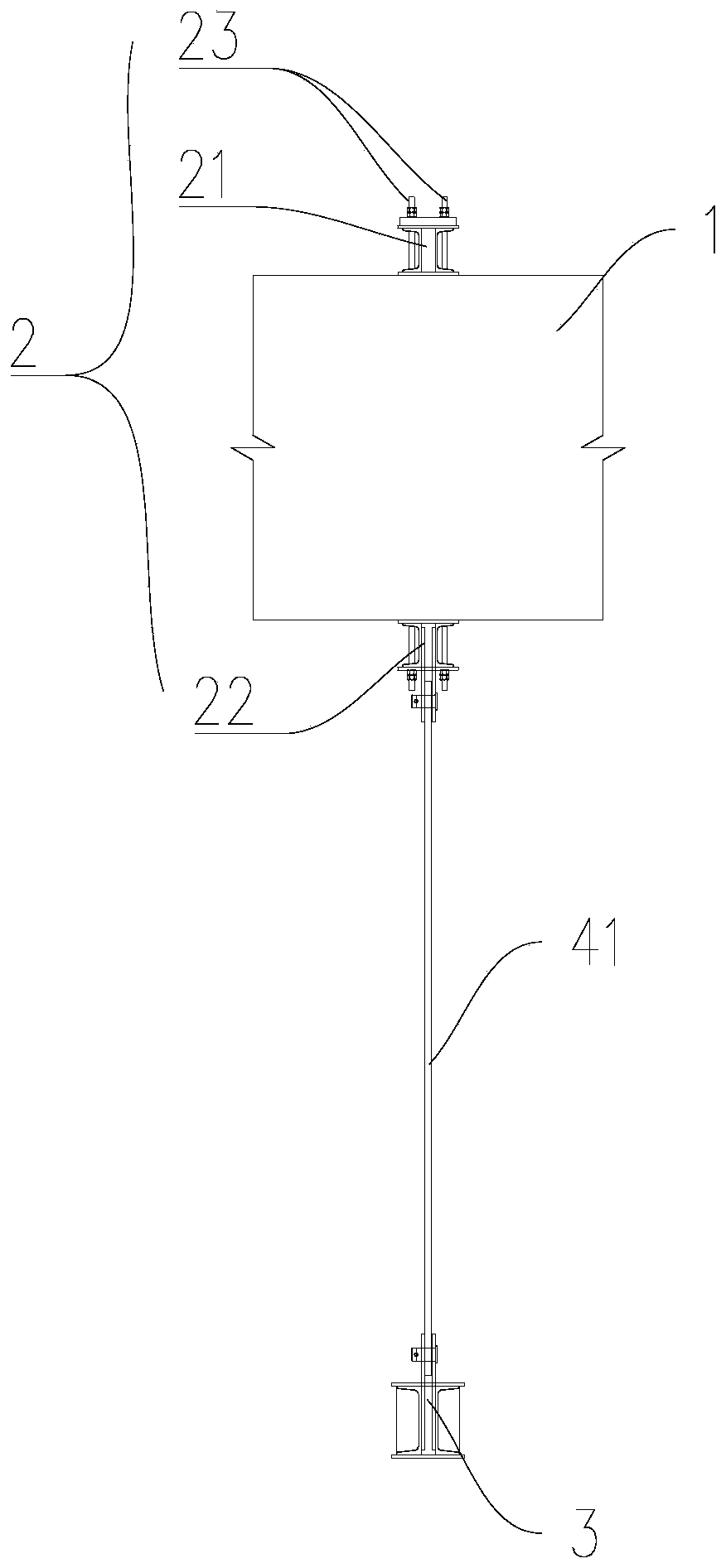

[0043] see Figure 1~2 As shown, the embodiment of the present invention provides an existing protective scaffolding for installation on the existing steel truss girder chord 1, including at least two sets of protective scaffolding units arranged at intervals, and the protective scaffolding units include:

[0044] An anchoring device 2, which is a hollow frame structure, and the anchoring device 2 is detachably clamped on the existing steel truss chord 1;

[0045] A lower beam 3, which is located below the anchoring device 2; and

[0046] The connecting component 4 is detachably connected to the anchoring device 2 and the lower beam 3 at both ends thereof.

[0047] In the embodiment of the present invention, the anchoring device 2 is a hollow frame structure, and the existing steel truss girder chord 1 is restricted in the hollow area of the anchoring device 2 for clamping, and the lower beam 3 is arranged on the anchoring device 2 through the connecting assembly 3 The low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com