Segmented acidifying method for low-pressure blocking horizontal well of ultra-low permeability oil deposit

A horizontal well, ultra-low permeability technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problems of short validity period, short validity period of daily liquid production decline, difficulty in establishing an effective displacement system, etc. To achieve the effect of convenient and simple construction and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

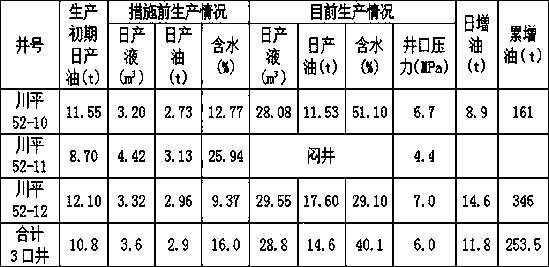

Examples

Embodiment 1

[0028] A method for staged acidizing of low-pressure plugged horizontal wells in ultra-low permeability reservoirs, comprising the following steps:

[0029] S1. According to the reservoir characteristics of ultra-low permeability reservoirs, select the type of horizontal well pattern, specifically five-point area well pattern or seven-point area well pattern;

[0030] S2. According to the well pattern of the horizontal well selected in step S1, design the structure of the multi-stage sliding sleeve acidizing string, then connect the multi-stage sliding sleeve acidizing string, and lower the connected multi-stage sliding sleeve acidizing string into the wellbore of the horizontal well until design location;

[0031] S3. According to the pattern of horizontal wells selected in step S1, design the corresponding number of acidizing construction layers, and deploy the operation mode of each layer;

[0032] S4. Carry out acidizing operation or joint operation of acidizing and reple...

Embodiment 2

[0037] On the basis of Example 1, in the step S2, the multi-stage sliding sleeve acidizing string includes a check valve, an injector, a first-stage sliding sleeve seat, and a first-stage K344 packer that are sequentially connected from the bottom of the well to the wellhead. Device, first-level sliding sleeve injector, first-level chamfering tool tubing, second-level sliding sleeve seat, second-level K344 packer, second-level sliding sleeve injector, second-level chamfering tool tubing... n-level sliding sleeve seat, N-level K344 packer, n-level sliding sleeve injector, n-level chamfering tool tubing, n-level K344 packer, n-level chamfering tool tubing and tool tubing.

[0038] Furthermore, the multi-stage sliding sleeve acidizing string of the five-point area well pattern includes a check valve, an injector, a first-stage sliding sleeve seat, a first-stage K344 packer, and a first-stage sliding sleeve connected sequentially from the bottom of the well to the wellhead. Sleeve...

Embodiment 3

[0041]On the basis of Example 1, further, in the step S3, when the selected horizontal well pattern is a five-point area well pattern, the number of acidizing construction layers of the five-point area well pattern is designed to have 4 sections, wherein 1, The acidizing operation is carried out in the 4th section, and the combined operation of acidizing and replenishing energy is carried out in the 2nd and 3rd sections; when the selected horizontal well pattern is a seven-point area well pattern, the number of acidizing construction sections of the seven-point area well pattern is designed to be 5 sections, of which 2 1, 4 sections carry out combined operation of acidification and supplementary energy, and 1, 3, 5 sections carry out acidizing operation.

[0042] Furthermore, the acid liquid used in the acidizing operation is organic earth acid, and the pumping volume is 30-40 m 3 , with a displacement of 1.0-2.0 m 3 / min, the liquid used in the energy replenishment operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com