pressure fastener

A fastener and pressure technology, applied in the direction of threaded fasteners, locking fasteners, connecting components, etc., can solve the problems of easy nut retraction and difficulty for workers to fasten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

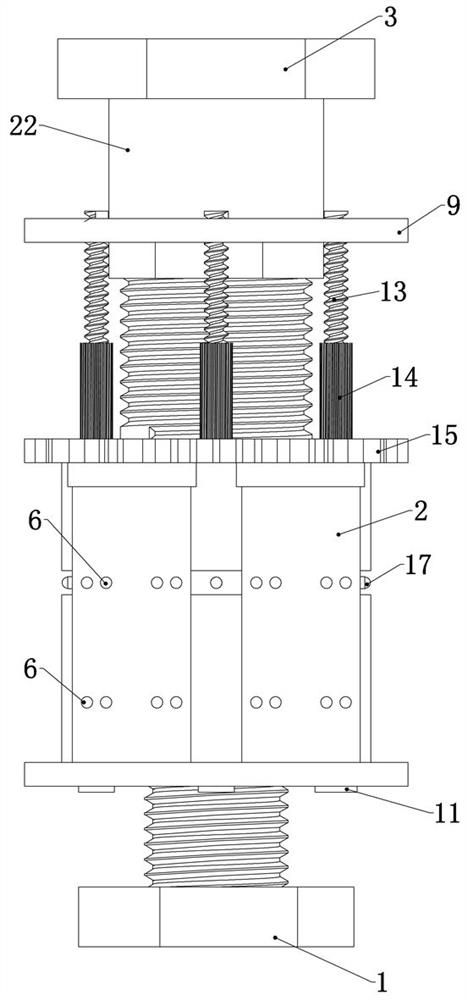

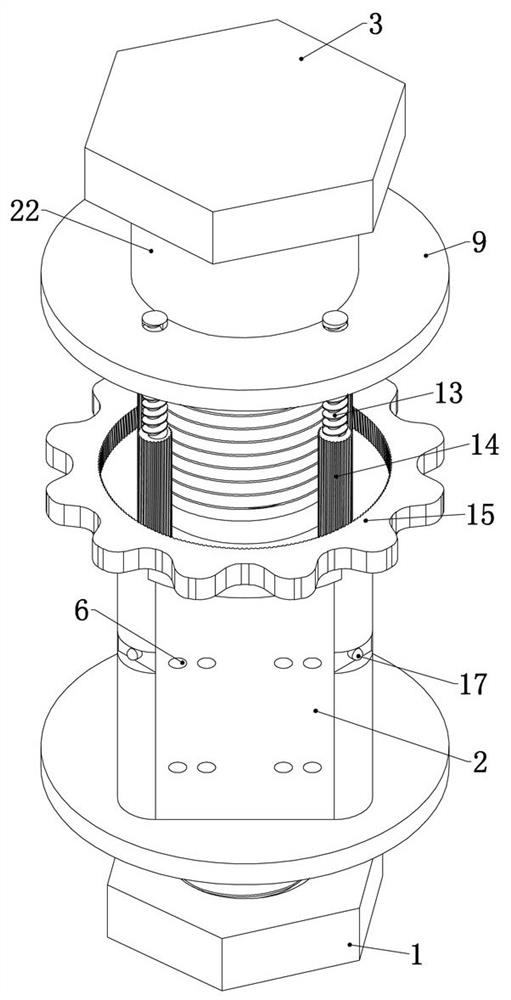

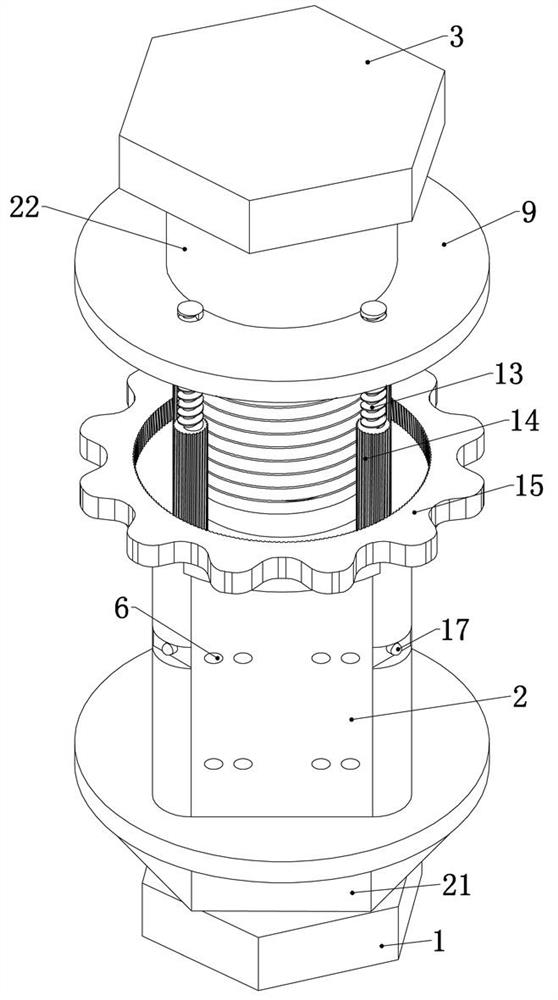

[0033] Embodiment 1, the present invention is a pressure fastener, including a bolt 1, which is characterized in that the external thread of the bolt 1 is provided with a threaded sleeve 2, and the outer wall of the upper end of the threaded sleeve 2 is provided with threads. The upper threaded sleeve of the threaded sleeve 2 is provided with a nut 3, and the lower end of the nut 3 is fixedly connected with an elastic member 4 arranged inside the threaded sleeve 2. The elastic member 4 can be a spring 18, or can be Spring steel sleeves, or even common elastic parts 4 such as air pressure devices or oil pressure devices, after the two drain plates clamp the wires, pass the bolt 1 through the fixing holes of the two drain plates, and set the threaded sleeve 2 on the Screw on the bolt 1 and tighten it, and then tighten the nut 3. At this time, the nut 3 compresses the elastic member 4, and the restoring force of the elastic member 4 acts upward and downward at the same time. Under...

Embodiment 2

[0037] Embodiment 2. On the basis of Embodiment 1, this embodiment provides a specific structure, so that the threaded sleeve 2 can be closely connected with the drainage plate in contact. Specifically, the lower end of each air passage 5 is A booster hole 10 is provided, and each of the booster holes 10 is coaxially provided with a rubber ring 11 fixedly connected to the bottom of the threaded sleeve 2. In the specific use of this embodiment, the threaded sleeve 2 is placed on the Bolt 1 is screwed on and stopped until the rubber ring 11 is in contact with the upper drain plate, or it can also be screwed one more turn to stop after the rubber ring 11 contacts the upper drain plate, so that the rubber ring 11 and the drain plate are in close contact. To prevent air leakage, after that, turn the nut 3 to drive the lower piston 8 to move upward, so that the drainage plate can be firmly sucked under the threaded sleeve 2 through the booster hole 10, so that the device and the drai...

Embodiment 3

[0038]Embodiment 3. On the basis of Embodiment 1, this embodiment provides a specific way in which the upper piston 7 is connected to the push ring 9, so that the initial position of the upper piston 7 can be adjusted. Specifically, the upper piston 7 on the push ring 9 There are several threaded holes 12, and the upper end of each upper piston 7 is rotatably connected with a screw 13, and the upper end of each said screw 13 cooperates with several threaded holes 12 on the push ring 9 respectively, and each said screw The middle part of 13 is coaxially fixedly connected with a screw gear 14, and the outside of the threaded sleeve 2 is coaxially rotatably connected with an outer ring gear 15 meshing with several of the screw gears 14 at the same time, and the outer ring gear 15 rotates It can drive some screw gears 14 meshed with it to rotate, and drive the corresponding screw rod 13 to rotate. At this time, because the push ring 9 is rotated and connected to the nut 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com