Variable inner diameter flange assembly

A flange and inner diameter technology, which is applied in the field of variable inner diameter flange components, can solve the problems of labor waste, capacity waste, and increased production costs, and achieve the effects of improving equipment utilization, reducing production costs, and reducing production change time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

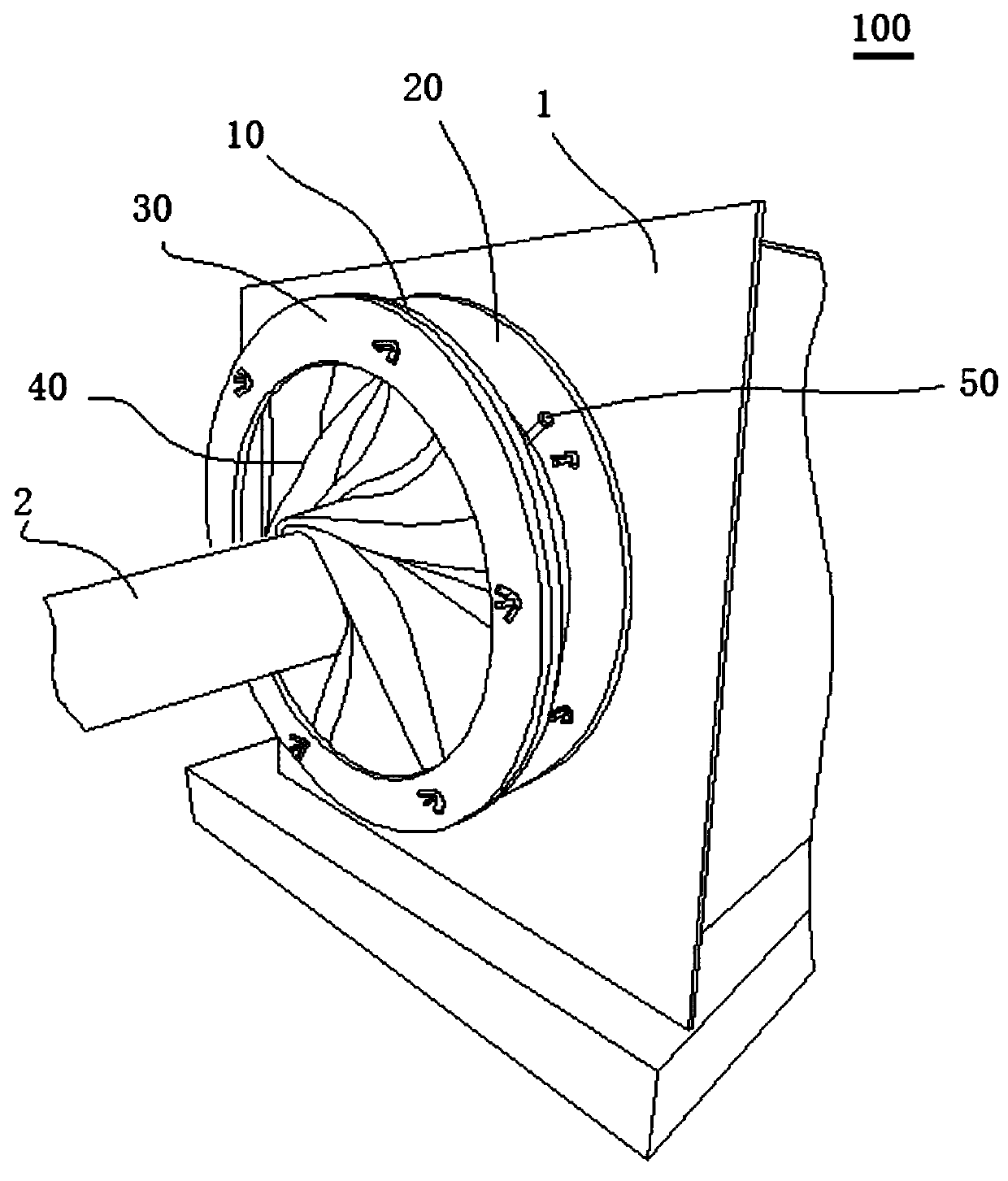

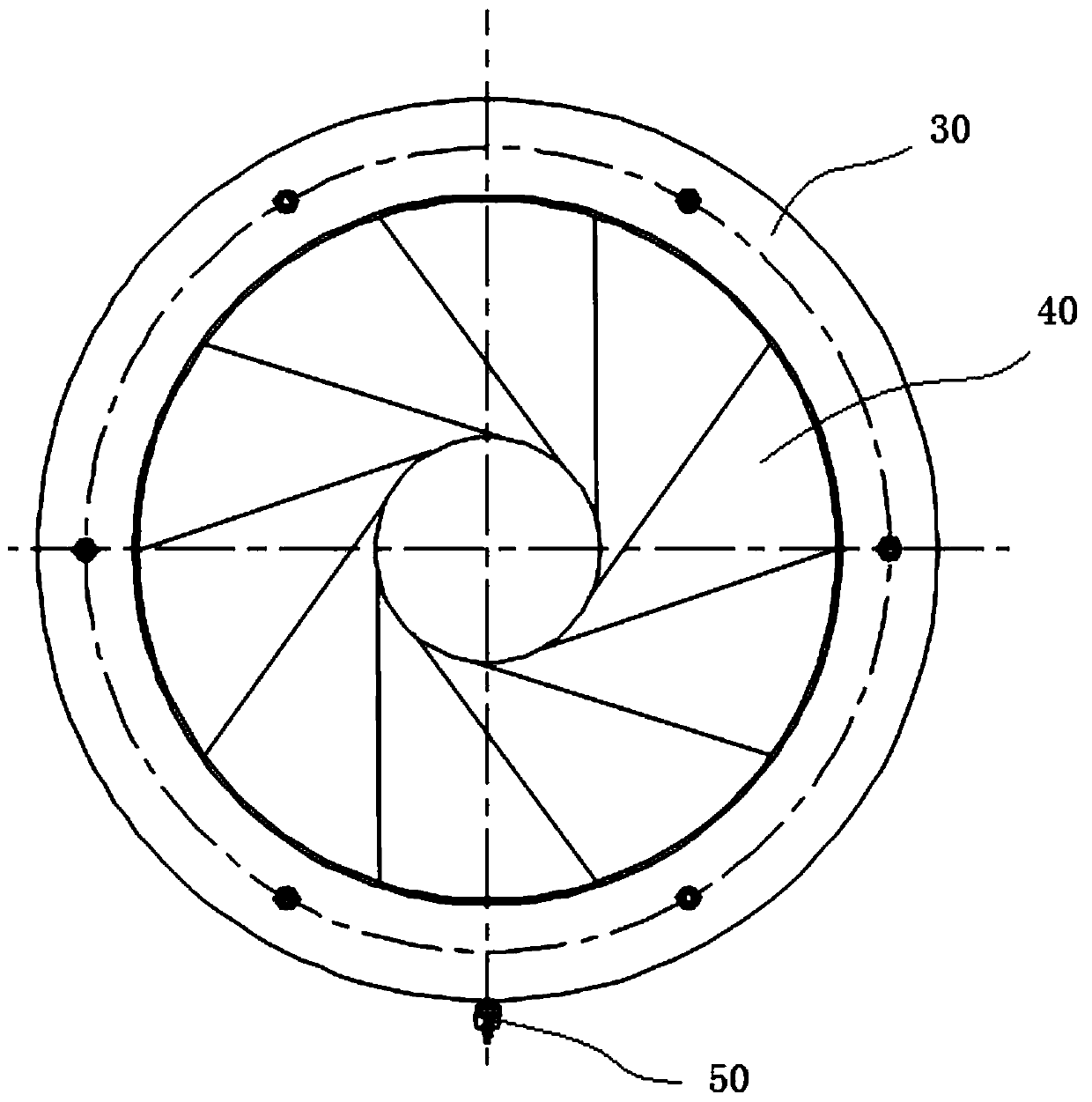

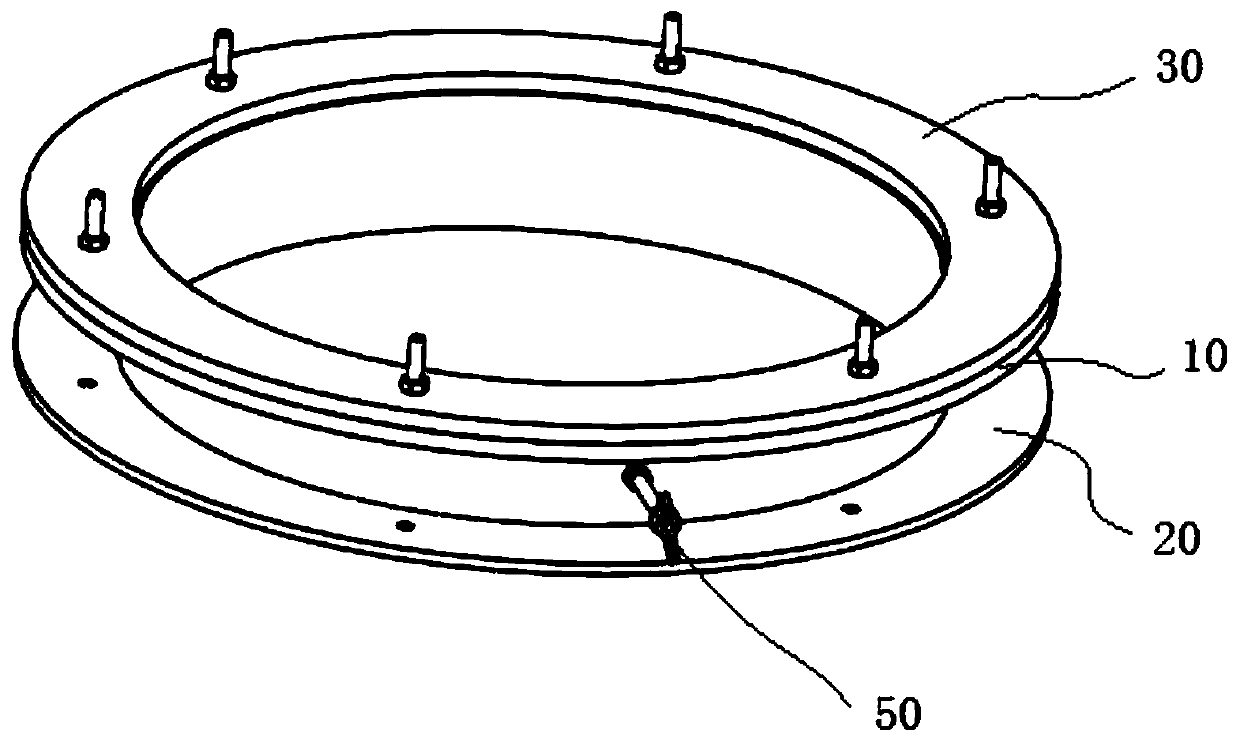

[0042] figure 1 It is a schematic perspective view of a variable inner diameter flange assembly according to an embodiment of the present application. figure 2 Yes figure 1 A schematic front view of the variable inner diameter flange assembly shown. image 3 Yes figure 1 A schematic front view of the variable inner diameter flange assembly shown with the flexible sleeve removed. Figure 4 Yes figure 1 A schematic back view of the variable inner diameter flange assembly shown with the flexible sleeve removed. Figure 5 Yes figure 1 The shown schematic assembly drawing of the variable inner diameter flange assembly with the flexible sleeve removed. Image 6 Yes Figure 5 A schematic partial enlarged view at middle A. Picture 10 Yes Figure 5 A schematic partial enlarged view when the flexible sleeve is installed at center A.

[0043] Such as figure 1 Shown, see also Figure 2-Figure 6 This embodiment provides a variable inner diameter flange assembly 100, which includes an upper fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com