Gas cylinder drawstring transportation support

A gas cylinder and the same technology, applied in the field of transport brackets, can solve the problems of easy damage to the surface paint layer of the gas cylinder pull strap, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

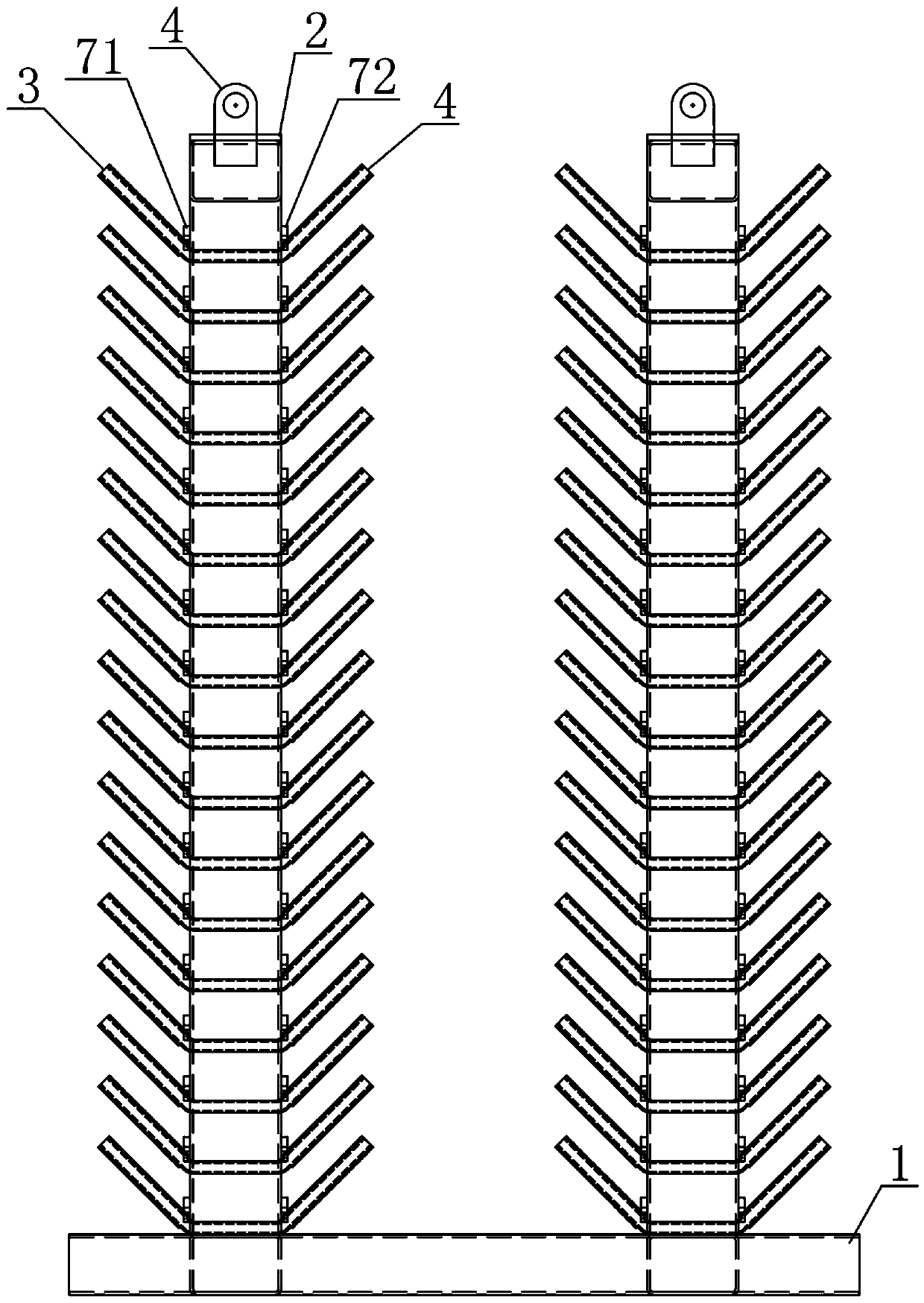

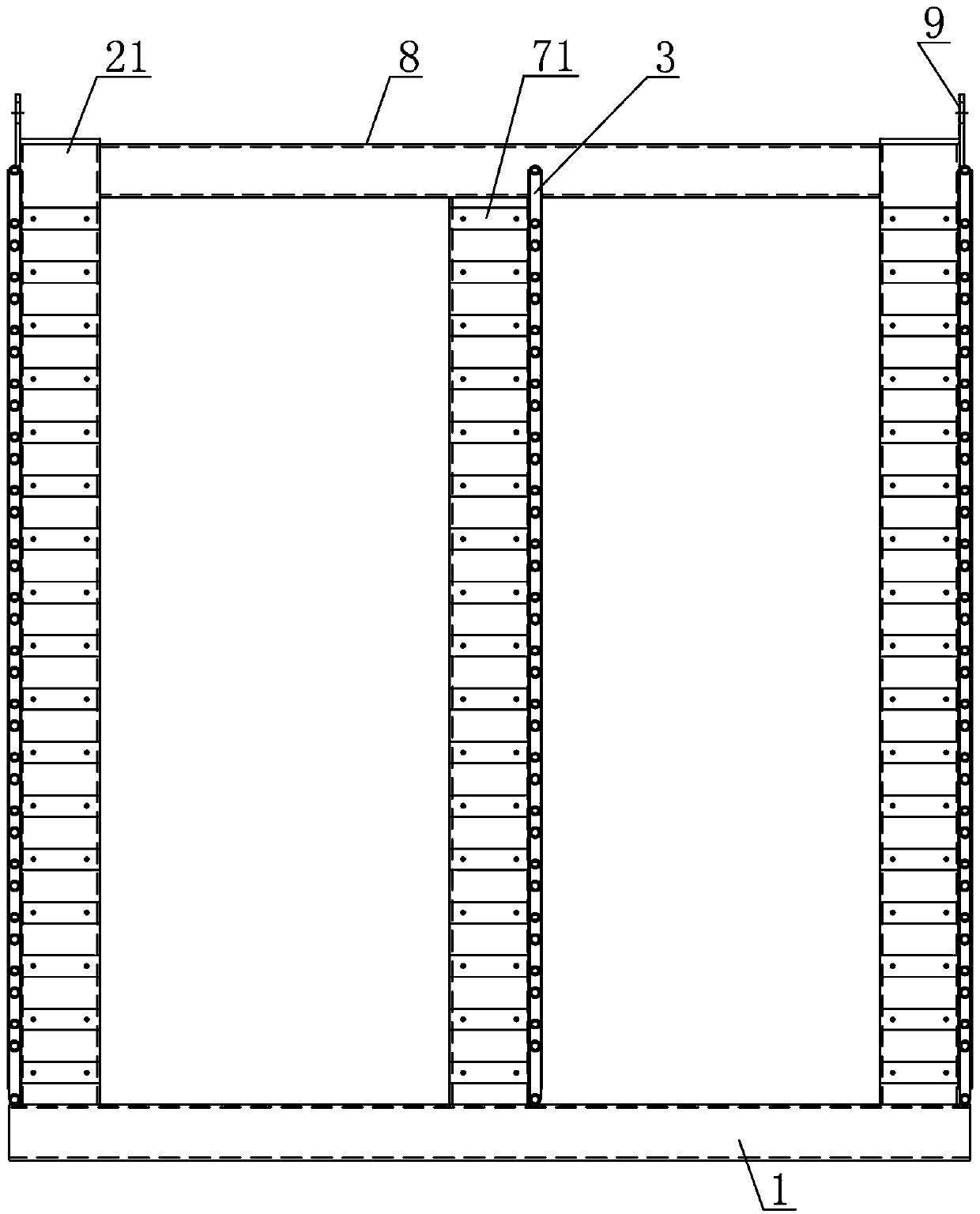

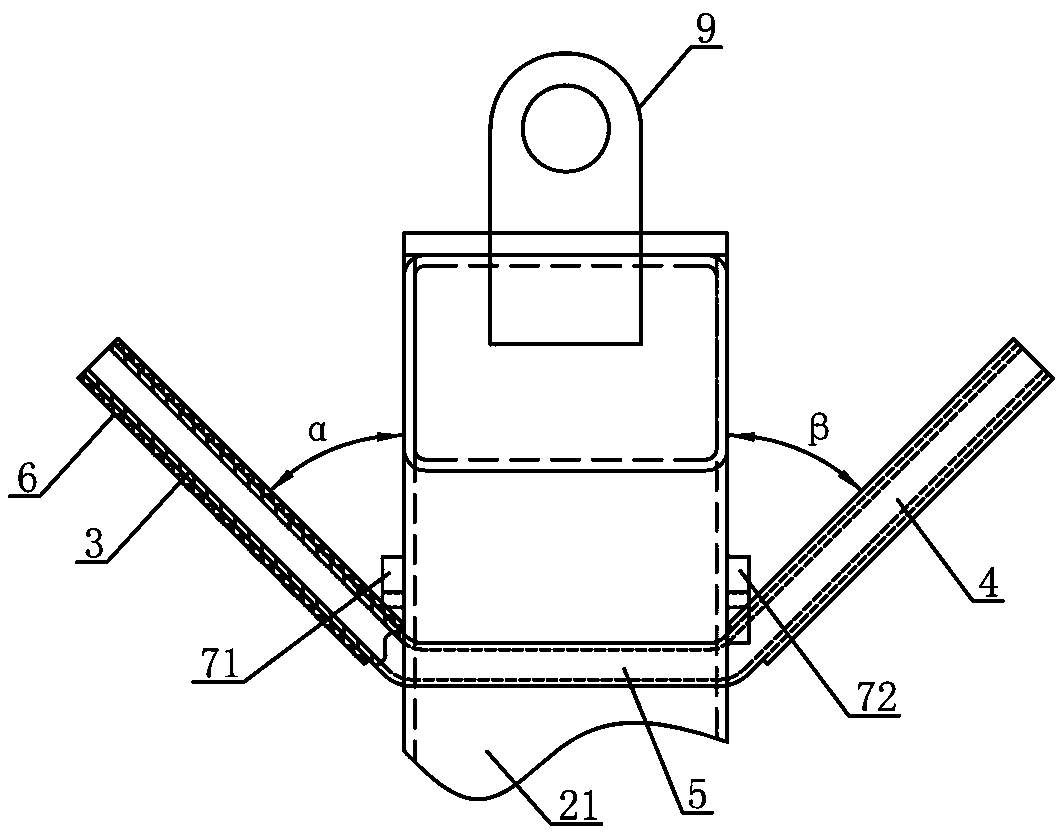

[0020] Such as figure 1 , figure 2 and image 3 As shown, a gas cylinder strap transport bracket described in this embodiment includes: a rectangular frame base 1, on which at least one row of vertical rod groups 2 is arranged at intervals from front to rear, and each row of vertical rods The rod groups 2 are all composed of at least two vertical rods 21 fixed vertically on the base of the rectangular frame, and the vertical rods 21 in each row of vertical rod groups 2 are arranged at intervals and lined up. In actual production, the vertical bars 21 in each row of vertical bar sets 2 are evenly spaced. A number of first support rods 3 are arranged at intervals from top to bottom on each vertical rod 21, each first support rod 3 is located at the front side of the corresponding vertical rod 21 and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com