Passive self-collimation parallelism calibration platform and system

A calibration platform and self-collimation technology, which is applied in the field of optical inspection, can solve the problems of not receiving test chart instruments, etc., and achieve the effect of strong versatility and small overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present application will be further described below in conjunction with the accompanying drawings and specific embodiments.

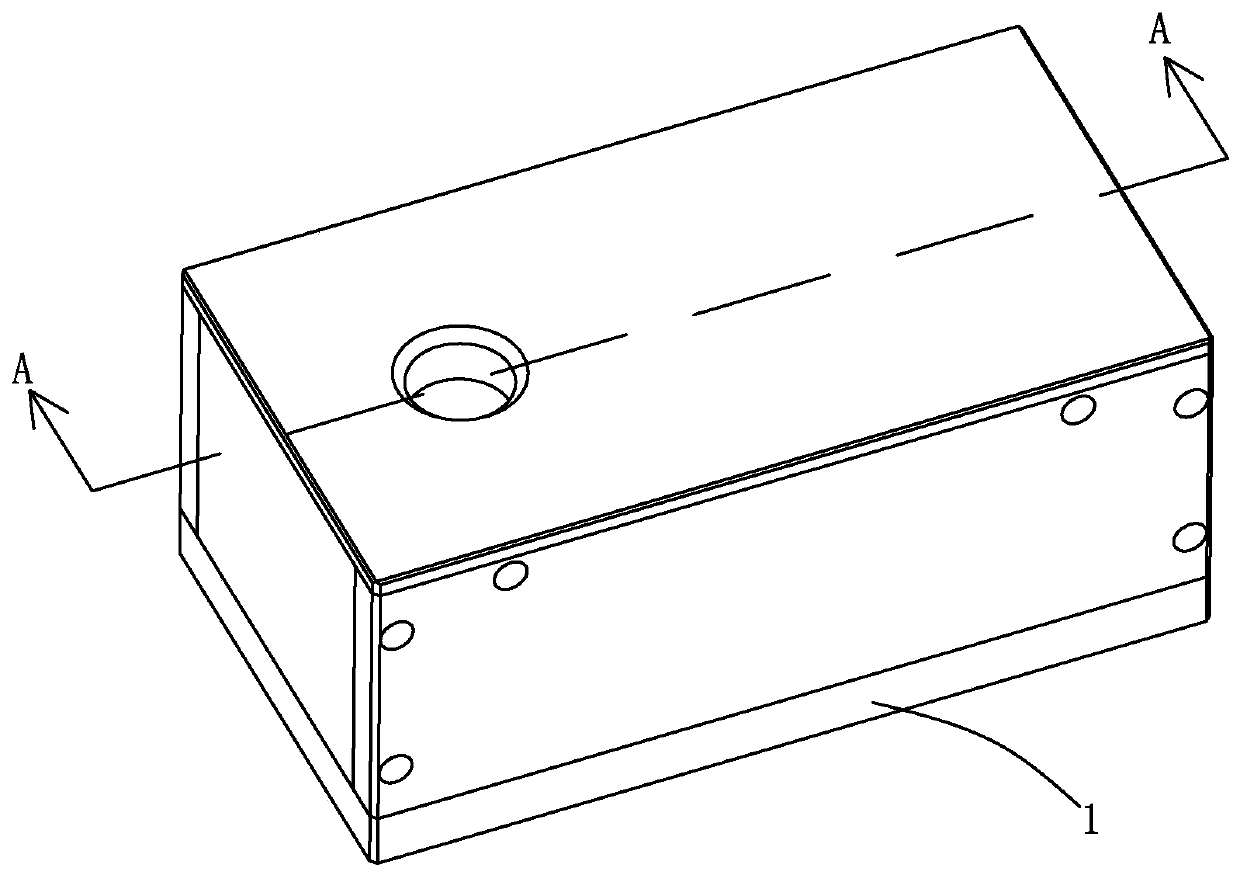

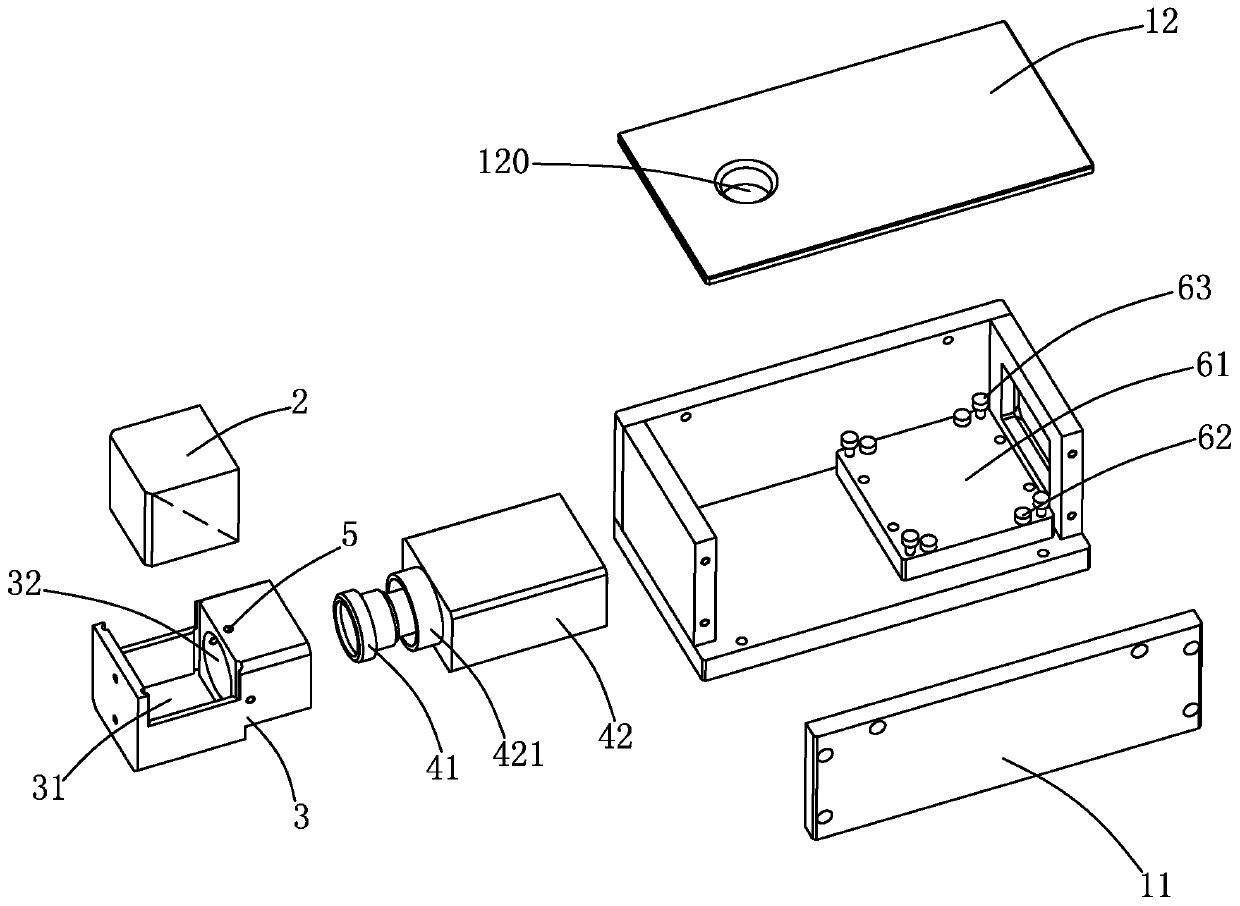

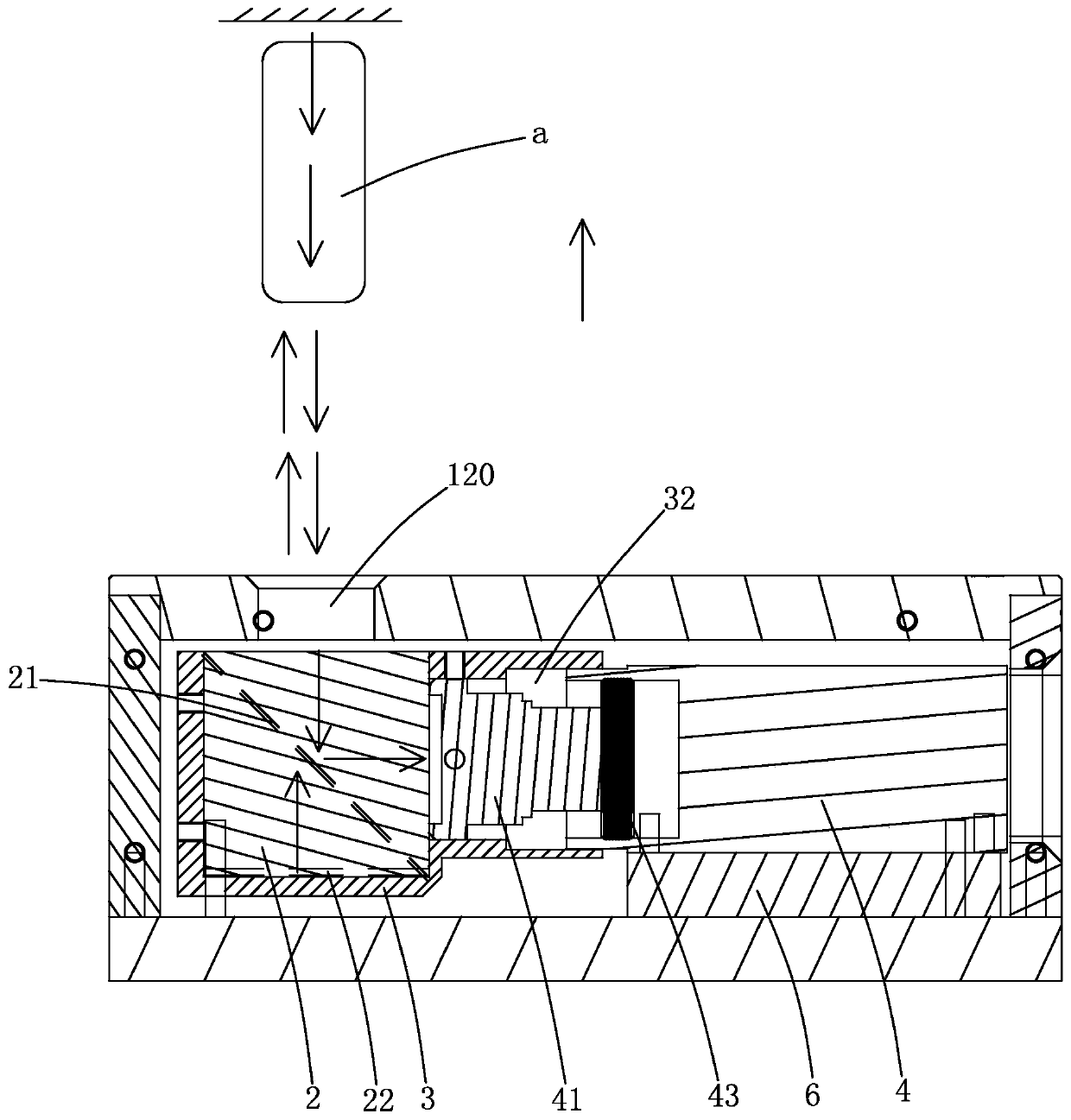

[0023] Please see attached figure 1 to attach image 3 , a passive self-collimation parallelism calibration platform, comprising a base plate 1, a side plate 11 fixed around the base plate and a cover plate 12 arranged on the top of the side plate, the base plate 1, the side plate 11 and the cover plate 12 are relatively surrounded by A semi-reflective and semi-transparent lens module 2 for reflecting parallel light rays is provided in the area of the semi-reflective and semi-transparent lens module. One side of the semi-transparent lens module 2 is provided with an image forming module 4 opposite to the semi-transparent reflective surface to allow reflected parallel light rays to enter, and the bottom of the semi-transparent lens module 2 is located at the semi-transparent surface. A total reflection surface 22 is provided on the lower s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com