A method for evaluating the compatibility of multi-component dyes

An evaluation method and multi-component technology, applied in the direction of analysis of materials, material excitation analysis, instruments, etc., can solve the problems of inability to truly reflect the dyeing process, quantitative analysis of compatibility, complicated and incapable processes, and achieve objective and reasonable results. Simple, easy-to-improve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of multi-component dye compatibility evaluation method of the present invention, its specific steps are as follows:

[0037] (1) Determine the threshold;

[0038] Collect D of multi-component dyes whose compatibility has been determined max , the multi-component dyes whose compatibility has been confirmed include 50 groups of multi-component dyes with good compatibility and 50 groups of multi-component dyes with poor compatibility. Component dye D max The maximum value of 1 is recorded as the threshold value, and the group of multi-component dyes whose compatibility has been determined is not limited to this, as long as it is guaranteed to include 2 groups of multi-component dyes with good compatibility and 2 groups of multi-component dyes with poor compatibility can;

[0039] (2) Dyeing the fabric;

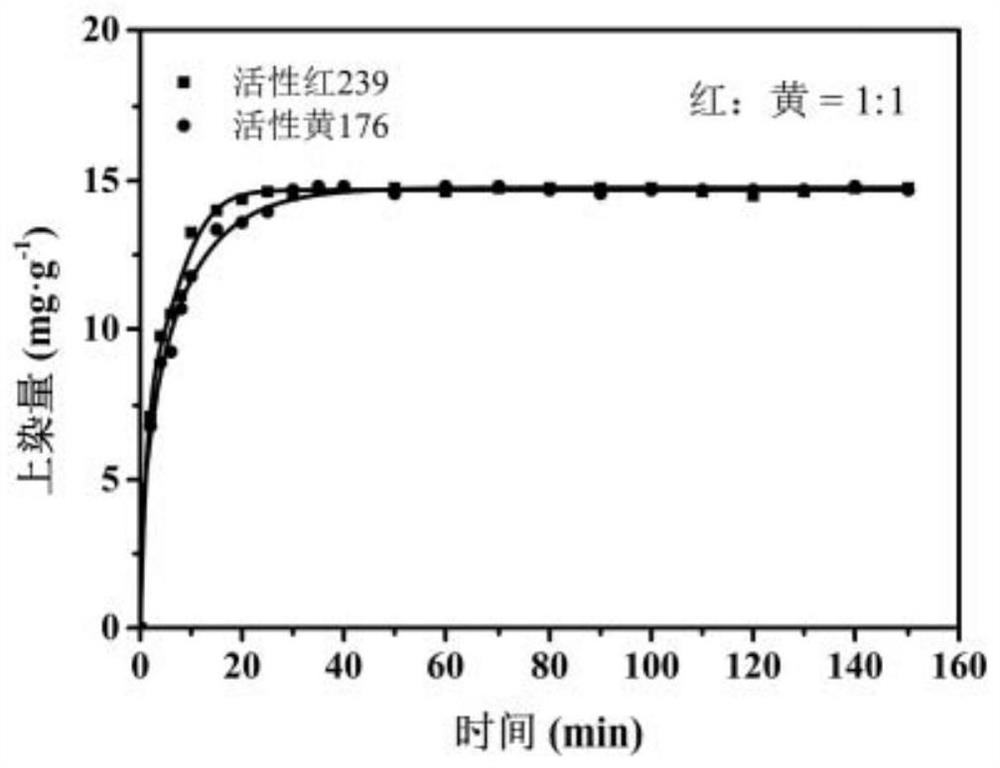

[0040] Blend reactive red 239 and reactive yellow 176 according to the mass ratio of 1:1 to form a dye solution with a concentration of 0.01g / L and a pH value o...

Embodiment 2

[0050] A kind of multi-component dye compatibility evaluation method of the present invention, its specific steps are as follows:

[0051] (1) Determine the threshold;

[0052] Same as embodiment 1;

[0053] (2) Dyeing the fabric;

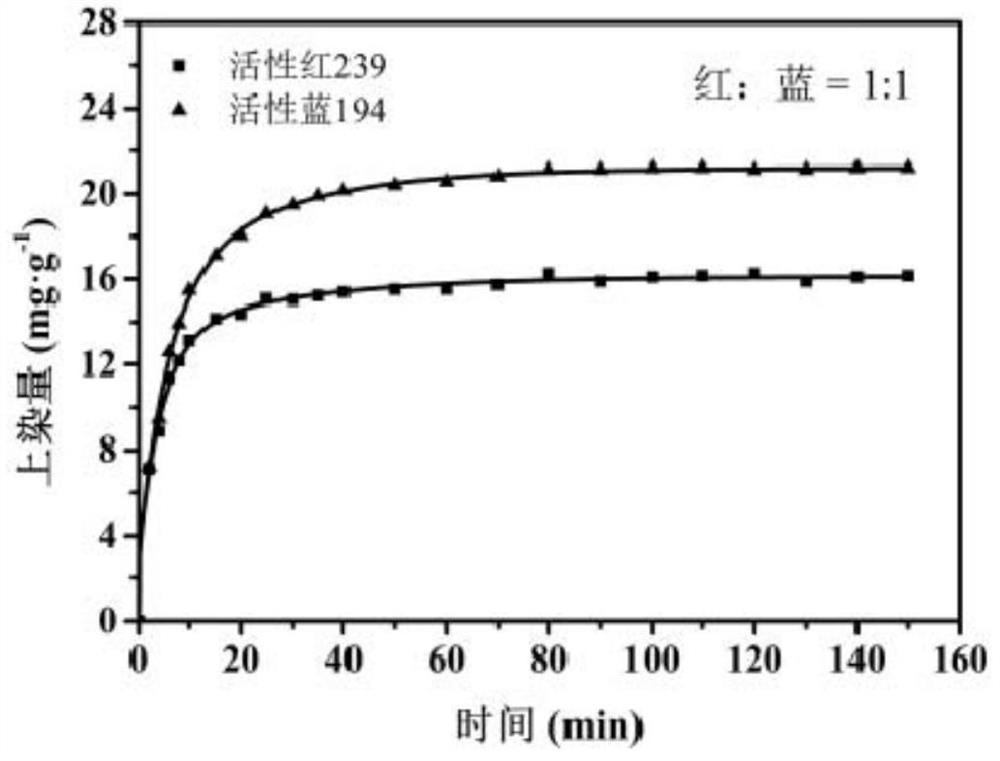

[0054] Reactive Red 239 and Reactive Blue 194 are mixed according to the mass ratio of 1:1 to form a dye solution with a concentration of 150g / L and a pH value of 7.0 to dye cotton fabrics. The dyeing temperature is 70°C and the liquor ratio is 1: 50, neutral salt (Na 2 SO 4 ) dosage is 0g / L, and the process is dip-dyeing;

[0055] (3) Evaluation of compatibility;

[0056] (3.1) Test the initial dye uptake rate of each dye on the fabric per unit mass in the dyeing process, and use it as the K of each dye 0 value, which is:

[0057] First, the Raman spectrometer is used to monitor the data of the concentration of each dye in the dyeing solution over time, and then the data is processed to obtain the data of the amount of each dye on the fabri...

Embodiment 3

[0064] A kind of multi-component dye compatibility evaluation method of the present invention, its specific steps are as follows:

[0065] (1) Determine the threshold;

[0066] Same as embodiment 1;

[0067] (2) Dyeing the fabric;

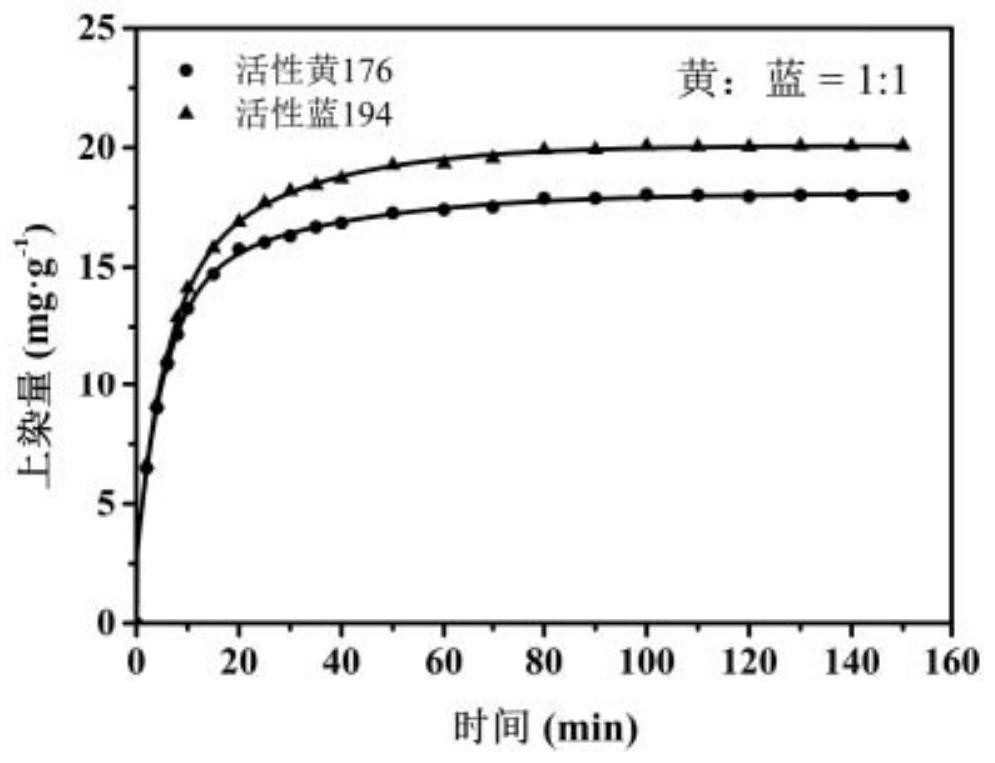

[0068] Reactive Yellow 176 and Reactive Blue 194 are blended according to the mass ratio of 1:1 to form a dye solution with a concentration of 200g / L and a pH value of 7.0 to dye cotton fabrics. The dyeing temperature is 10°C and the liquor ratio is 1: 200, neutral salt (Na 2 SO 4 ) dosage is 300g / L, and the process is cold pad-batch dyeing;

[0069] (3) Evaluation of compatibility;

[0070] (3.1) Test the initial dye uptake rate of each dye on the fabric per unit mass in the dyeing process, and use it as the K of each dye 0 value, which is:

[0071] First, the Raman spectrometer is used to monitor the data of the concentration of each dye in the dyeing solution over time, and then the data is processed to obtain the data of the amount of ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com