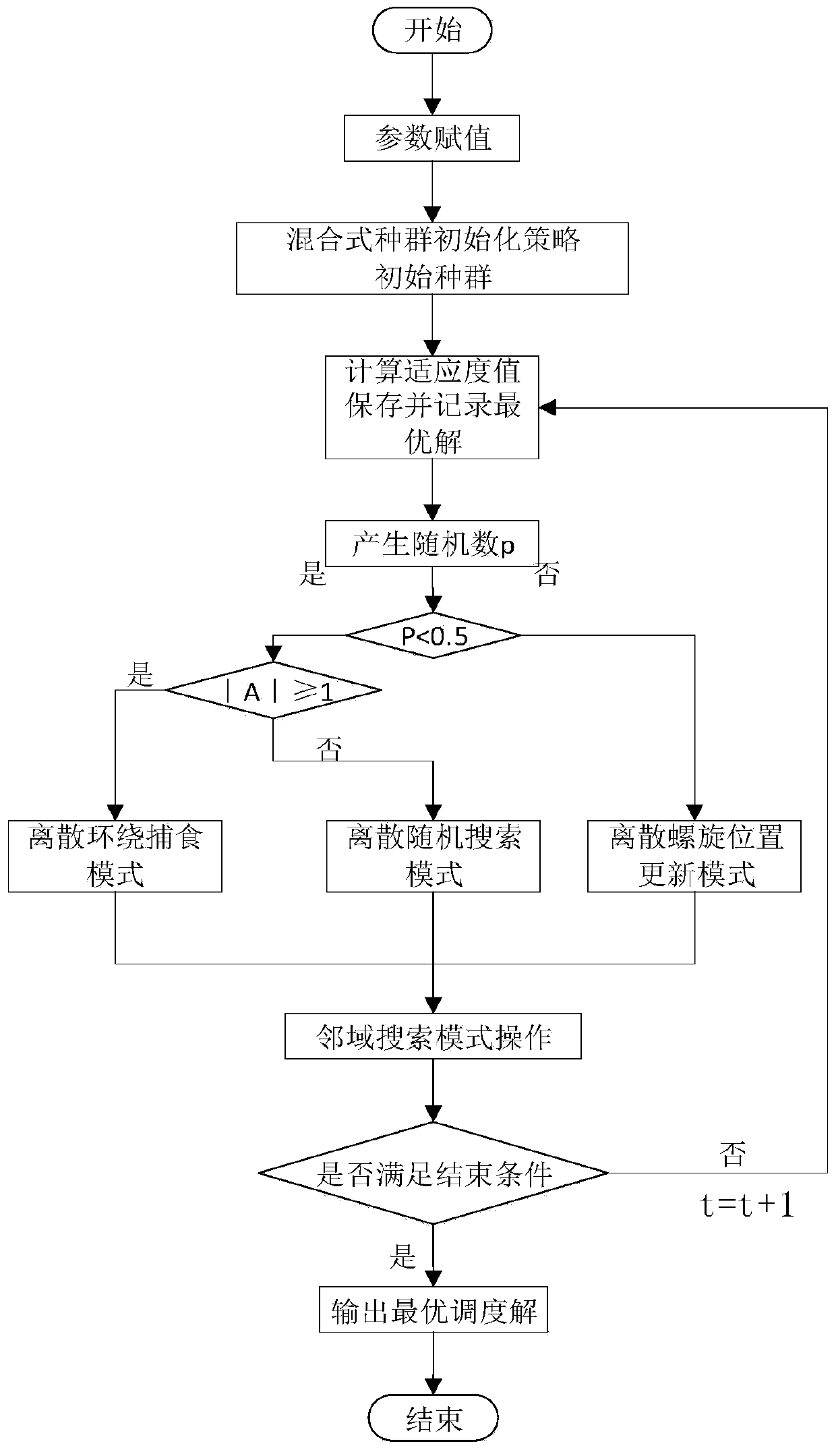

Method for solving low-carbon workshop scheduling problem on basis of discrete whale algorithm

A technology for workshop scheduling and scheduling problems, applied in control/regulation systems, instruments, comprehensive factory control, etc., can solve problems such as multi-objective complex optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

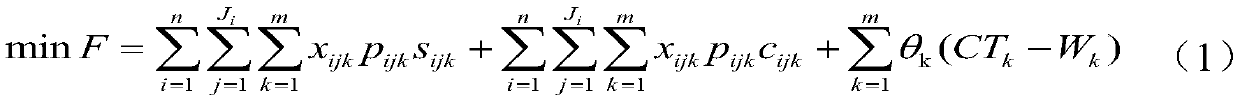

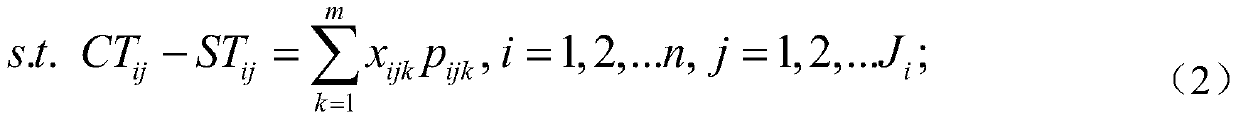

[0073] FJSP refers to the problem of arranging n workpieces to be processed on m processing equipment. Each workpiece has more than one processing procedure, and there is a fixed processing sequence between the procedures of the same workpiece, and one procedure can be processed on more than one device. While FJSP solves the processing sequence of the process, it also needs to select the appropriate processing equipment for the process. The common purpose of solving this problem is to minimize the maximum completion time, the minimum completion time cost, and the minimum average load of equipment. However, in today's low-carbon economic environment, enterprises must also consider energy consumption costs while completing processing tasks. The low-carbon flexible job shop scheduling problem is based on FJSP with the goal of minimizing carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com