Jig for bonding voice diaphragm and piezoelectric plate

A piezoelectric film and sound film technology, which is applied in the field of jigs for bonding sound film and piezoelectric film, can solve the problems of waste of raw materials and uncontrolled production costs, and achieve the effect of avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

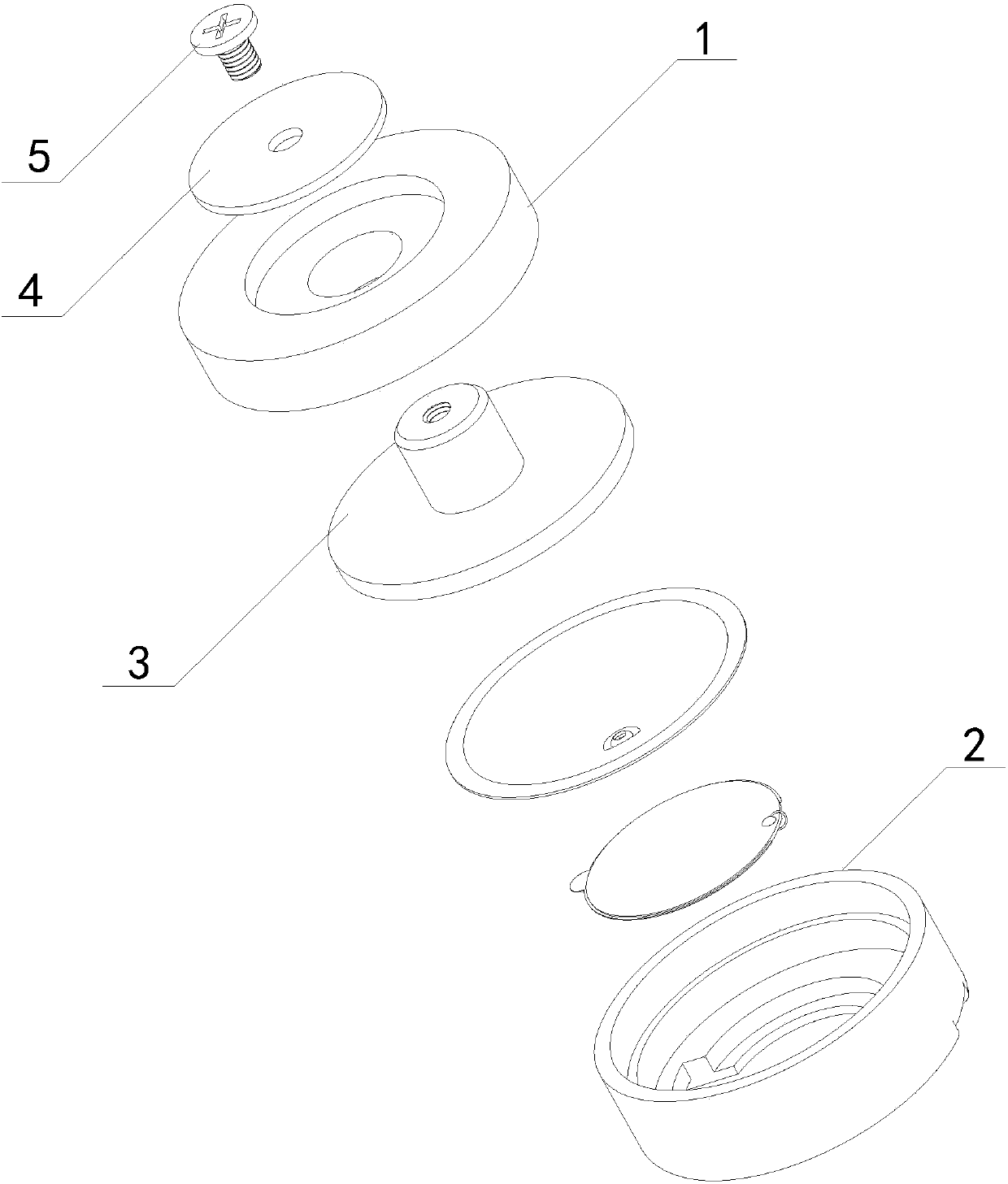

[0020] Such as figure 1 As shown, a fixture for the bonding of the sound film and the piezoelectric film according to the embodiment of the present application includes an upper box cover 1 and a lower box cover 2, the lower box cover 2 is an open circular box and is formed by a bottom plate 21 It is formed with the side wall 22. The bottom plate 21 and the side wall 22 are integrally formed. The inner diameter of the lower box cover 2 is equal to the bottom diameter of the conical sound film to be placed, that is, the sound film is regarded as a hollow circular platform, and the bottom surface is the area of the circular platform. Larger circular plane, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com