Vibration detection device and abnormality determination system

A technology of vibration detection and vibration wave, which is applied in the direction of measurement device, vibration measurement in fluid, measurement vibration, etc., can solve the problems of inability to check rotating machinery in real time, long processing time, etc., and achieve real-time detection and shorten the time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

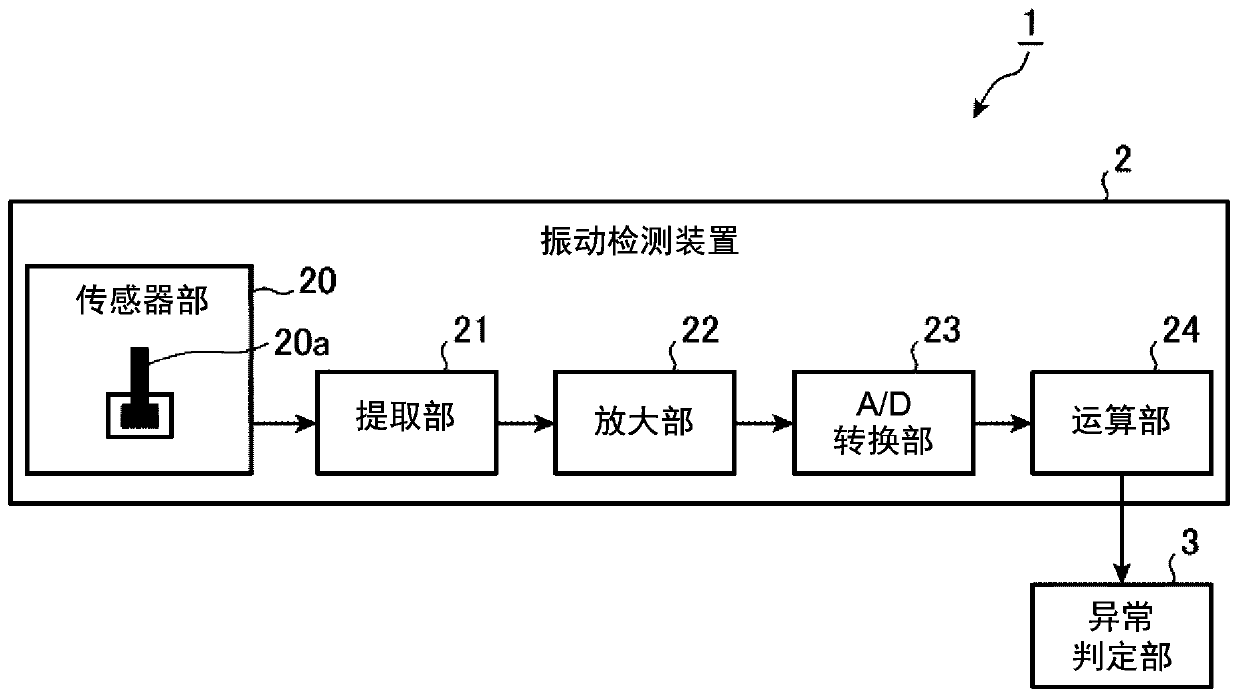

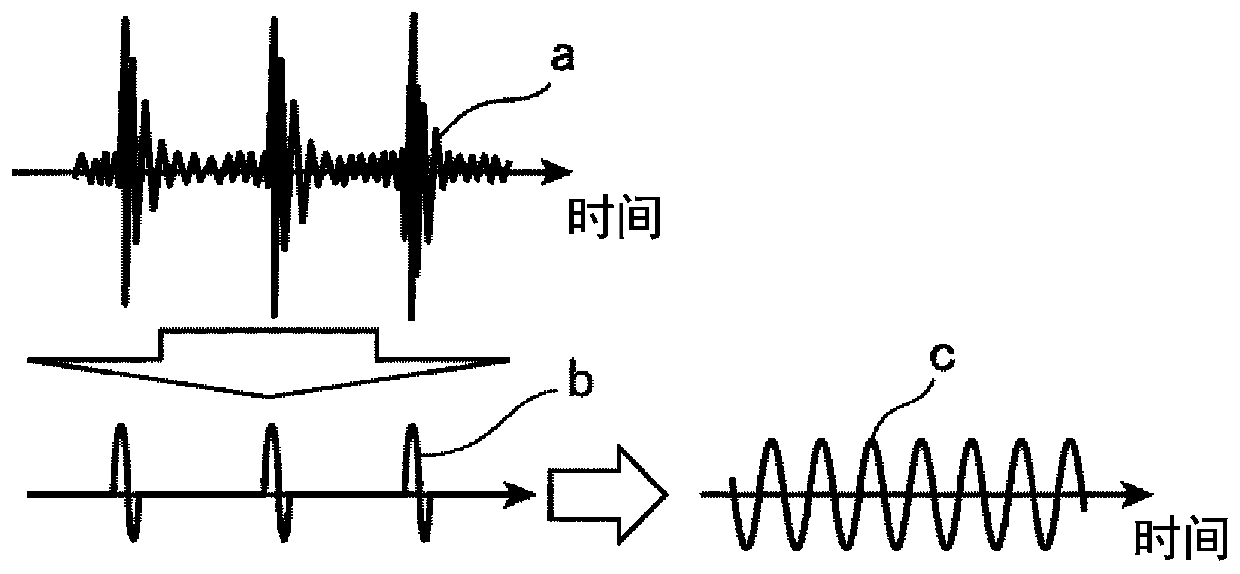

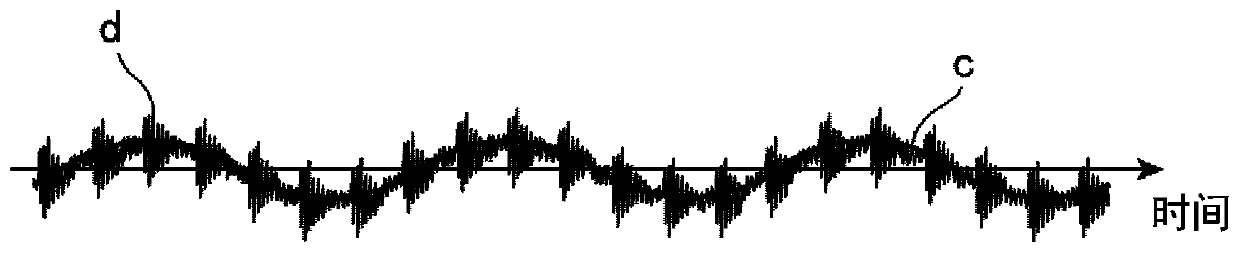

[0028] figure 1 It is a block diagram showing the configuration of the abnormality determination system 1 according to Embodiment 1 of the present invention. The abnormality determination system 1 is a system for determining an abnormality of a rotary machine based on vibration generated by the rotation of the rotary machine. Rotating machinery includes motors, reducers, cutting machines, pumps, and turbines. For example, when a bearing wears and an abnormality occurs, the vibration generated by the rotation of the rotary machine changes. The abnormality determination system 1 determines an abnormality of a rotating machine based on a change in vibration generated from a normal rotating machine. In addition, the abnormality determination system 1 includes a vibration detection device 2 and an abnormality determination unit 3 as constituent elements. The vibration detection device 2 includes a sensor unit 20 , an extraction unit 21 , an amplification unit 22 , an A / D convers...

Embodiment approach 2

[0063] Image 6 It is a block diagram showing the configuration of a vibration detection device 2A according to Embodiment 2 of the present invention. Image 6 in, right with figure 1 The same constituent elements are given the same reference numerals, and explanations thereof are omitted.

[0064] The vibration detection device 2A includes a sensor unit 20 , an extraction unit 21 , an amplification unit 22 , a filter unit 25 , and a comparison unit 26 . The filter unit 25 performs full-wave rectification or half-wave rectification on the sine wave signal amplified by the amplifying unit 22, and performs filtering (direct-current conversion) by a capacitor. The comparison unit 26 inputs a reference signal to be compared from inside or outside the system, compares it with the output signal of the filter unit 25, and determines whether the level is higher or lower than the reference signal. The determination result is output from the comparison unit 26 as an evaluation criter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com