Metal frame filter press filter plate

A technology of filter plate and metal frame of filter press, applied in the field of filter press, can solve the problems of reduced flow area, limited number of filter plates, clogging, etc. The effect of increasing the flow area and improving the discharge speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

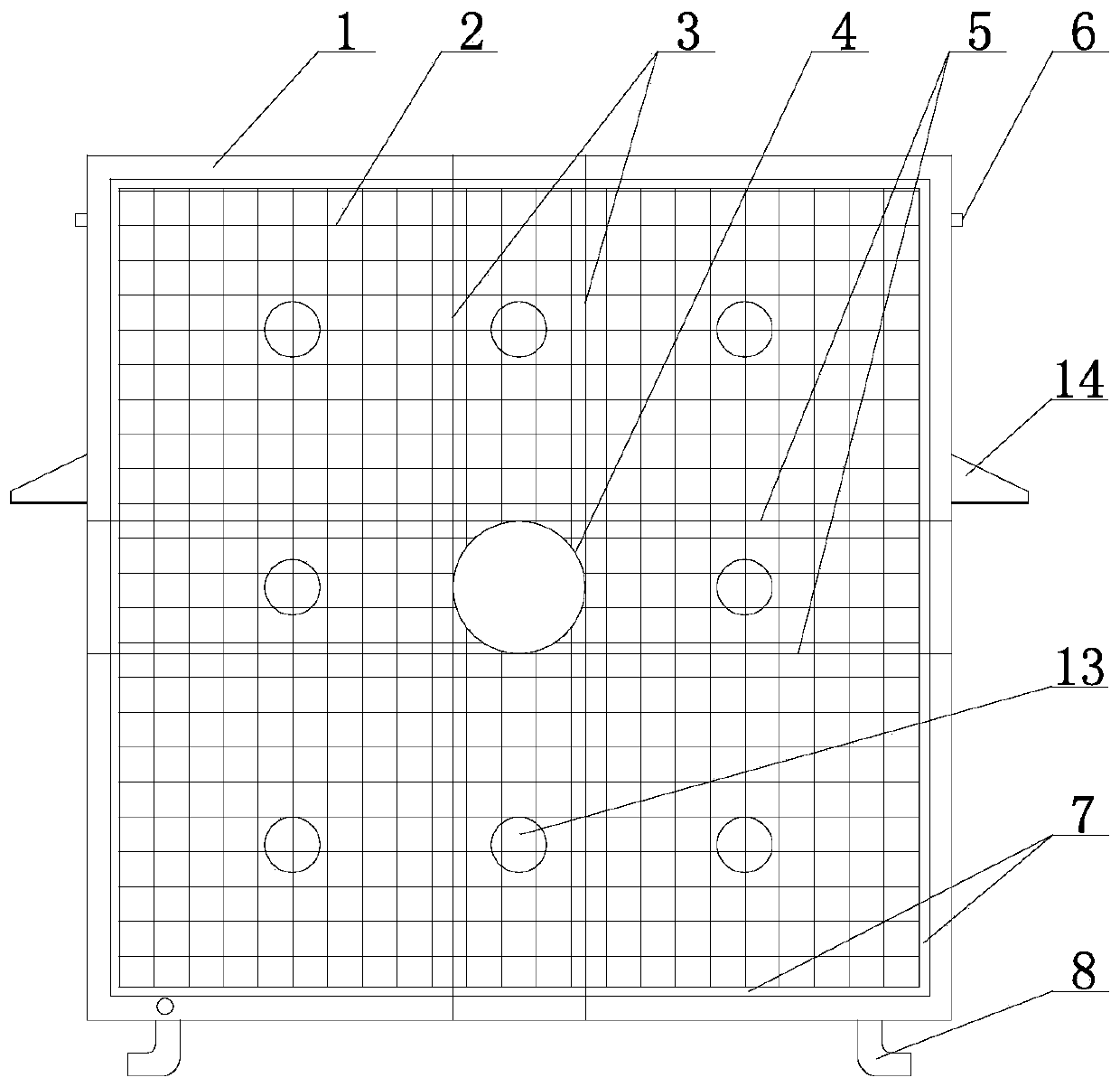

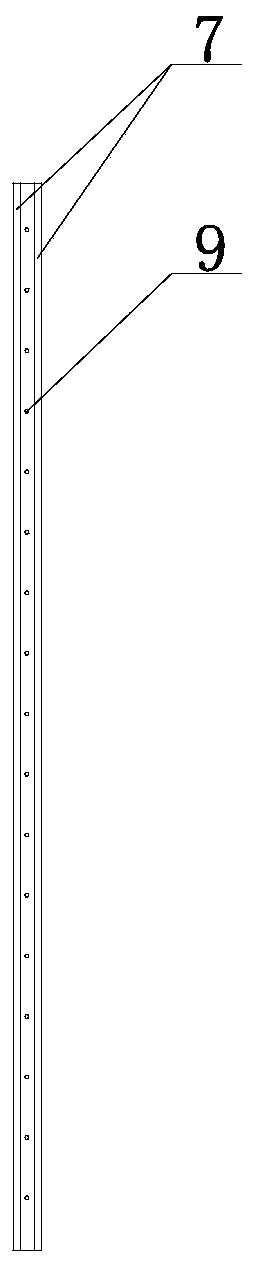

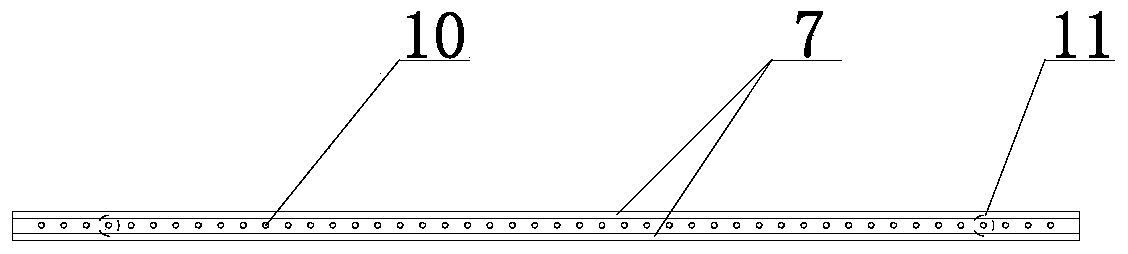

[0035] Such as Figure 1~4 As shown, the filter plate of the metal frame filter press in this embodiment includes a filter plate outer frame 1, a filter plate main body 2, a guide bracket 14 and a filtrate drain structure.

[0036] The main body of the filter plate 2 is a mesh welded by vertical and horizontal orthogonal strong acid and alkali resistant metal wires. In this embodiment, the diameter of the metal wire is 2mm, and the parallel spacing of each metal wire is 10mm. A feeding hole is opened in the central area, and a feeding ring 4 is welded at the feeding hole. The feeding hole in this embodiment is a circular hole, and the corresponding feeding ring 4 is also circular and designed with a diameter of 100 mm.

[0037] The upper and lower layers of the filter plate main body 2 are welded with two bracing steel wires with a diameter of 6mm. The bra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap