Environment-friendly composite board production cutoff device

A technology of cutting device and composite board, which is applied to sawing machine devices, attachment devices of sawing machines, metal sawing equipment, etc., can solve the problems of inconvenient feeding, inconvenient collection of debris, and inconvenient adjustment of plate positioning force, etc. Reduce labor intensity and avoid inconvenient collection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

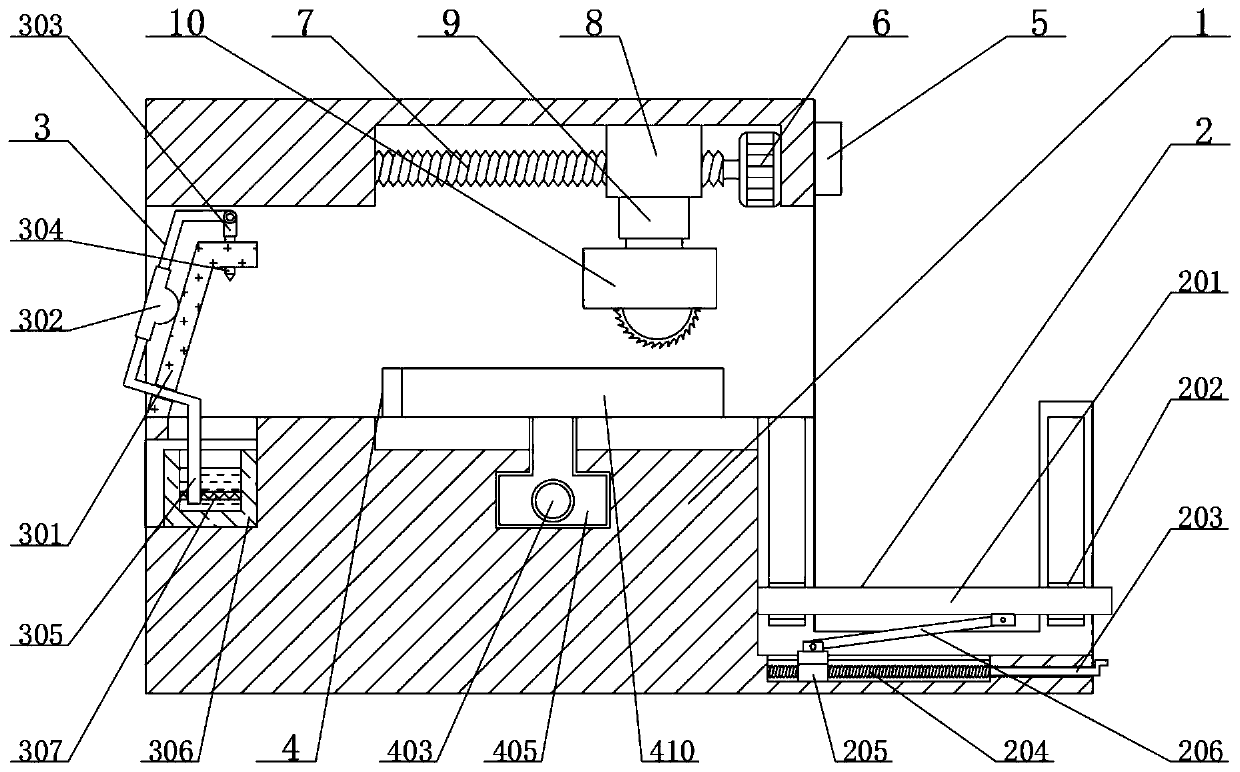

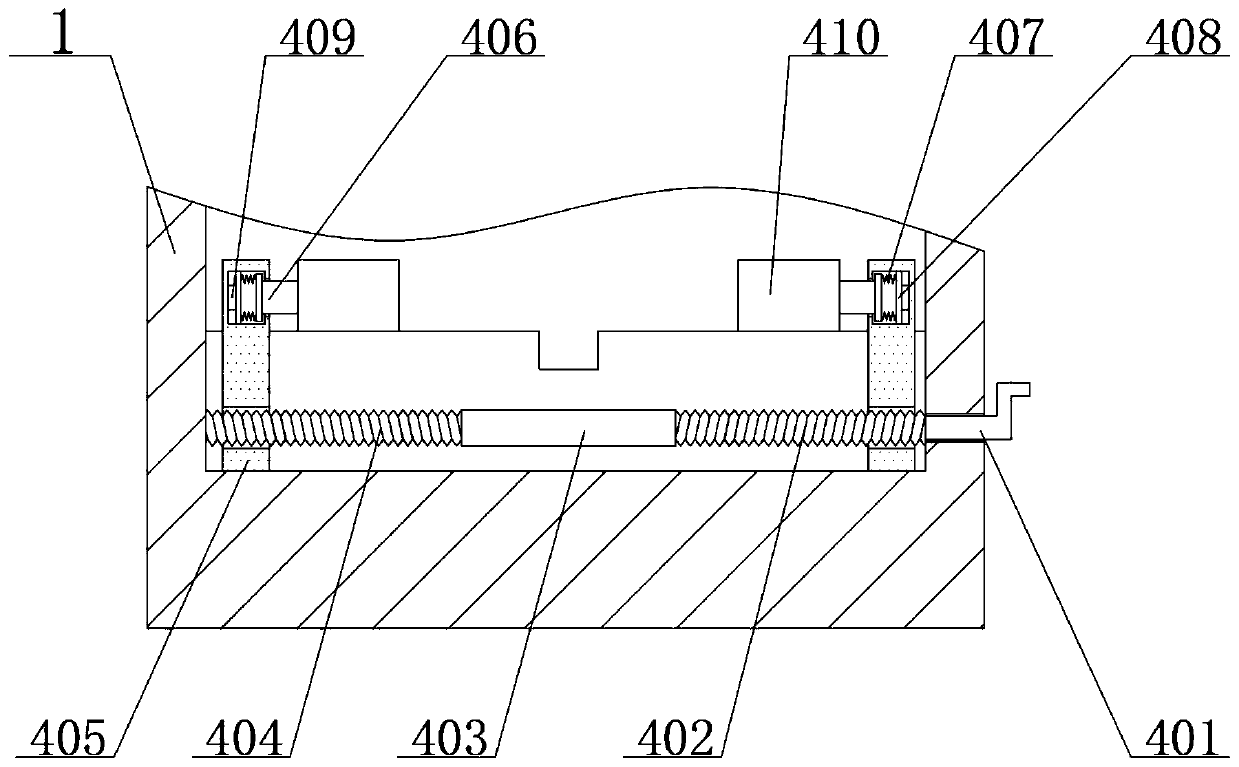

[0027] see figure 1 , image 3 , Figure 4 , Figure 5 and Figure 6 , the present invention provides a technical solution:

[0028]An environment-friendly cutting device for the production of composite boards, comprising a fixed frame 1, a feeding device 2, a collecting device 3 and a positioning device 4, the bottom end of the right side of the fixed frame 1 is provided with a feeding device 2, and the feeding device 2 includes a support plate 201, limit block 202, first handle 203, second threaded shaft 204, push block 205 and rotating rod 206, fixed frame 1 right side bottom end is provided with support plate 201, and support plate 201 is connected with fixed frame 1 slidingly, supports The outer side of the plate 201 is fixedly connected with the limit block 202, and the limit block 202 is slidingly connected with the fixed frame 1, and the bottom end of the right end surface of the fixed frame 1 is provided with a first handle 203, and the first handle 203 runs throu...

Embodiment 2

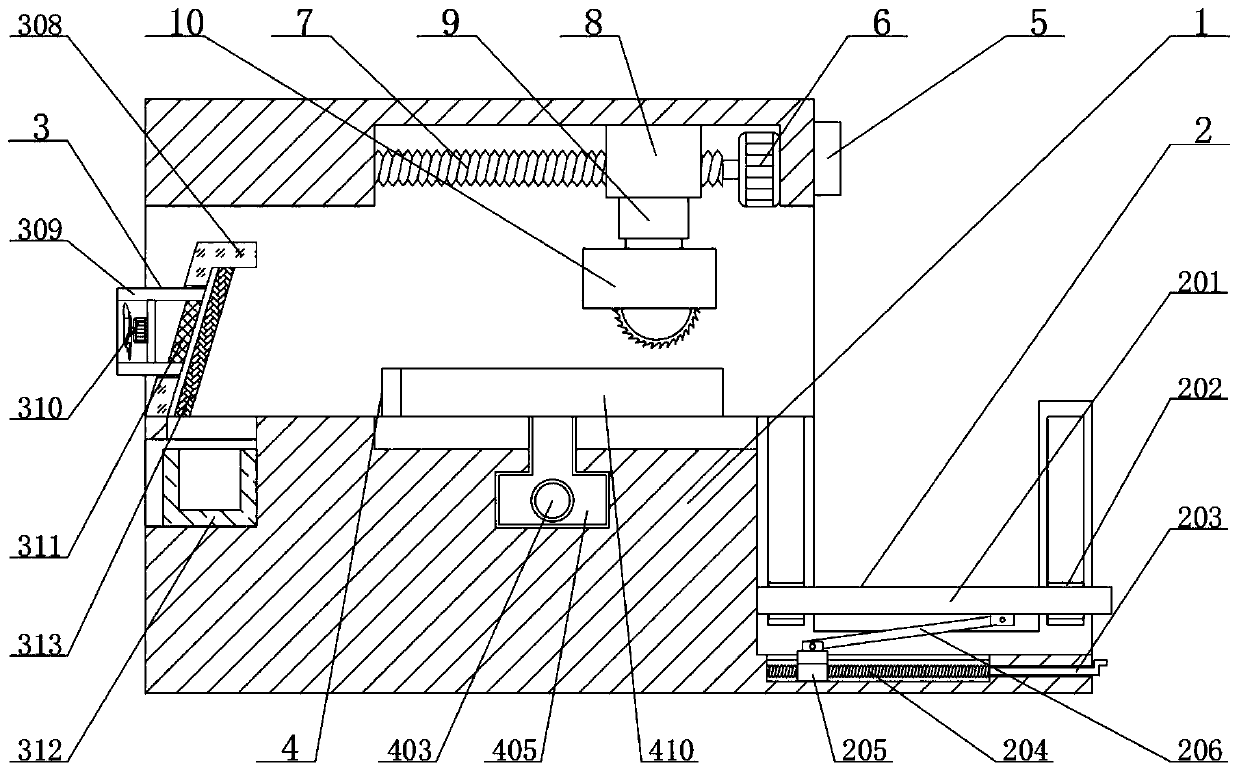

[0032] see figure 2 , image 3 and Figure 6 , the present invention provides a technical solution:

[0033] An environment-friendly cutting device for the production of composite boards, comprising a fixed frame 1, a feeding device 2, a collecting device 3 and a positioning device 4, the bottom end of the right side of the fixed frame 1 is provided with a feeding device 2, and the feeding device 2 includes a support plate 201, limit block 202, first handle 203, second threaded shaft 204, push block 205 and rotating rod 206, fixed frame 1 right side bottom end is provided with support plate 201, and support plate 201 is connected with fixed frame 1 slidingly, supports The outer side of the plate 201 is fixedly connected with the limit block 202, and the limit block 202 is slidingly connected with the fixed frame 1, and the bottom end of the right end surface of the fixed frame 1 is provided with a first handle 203, and the first handle 203 runs through the fixed frame 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com