Numerical control machining center-used convenient-to-use type device for clamping triangular workpieces

A workpiece clamp and triangular technology, which is applied to metal processing machine parts, positioning devices, metal processing equipment, etc., can solve the problems of affecting processing accuracy, unfavorable development and operation, and troublesome use, so as to improve processing accuracy, easy maintenance and repair, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

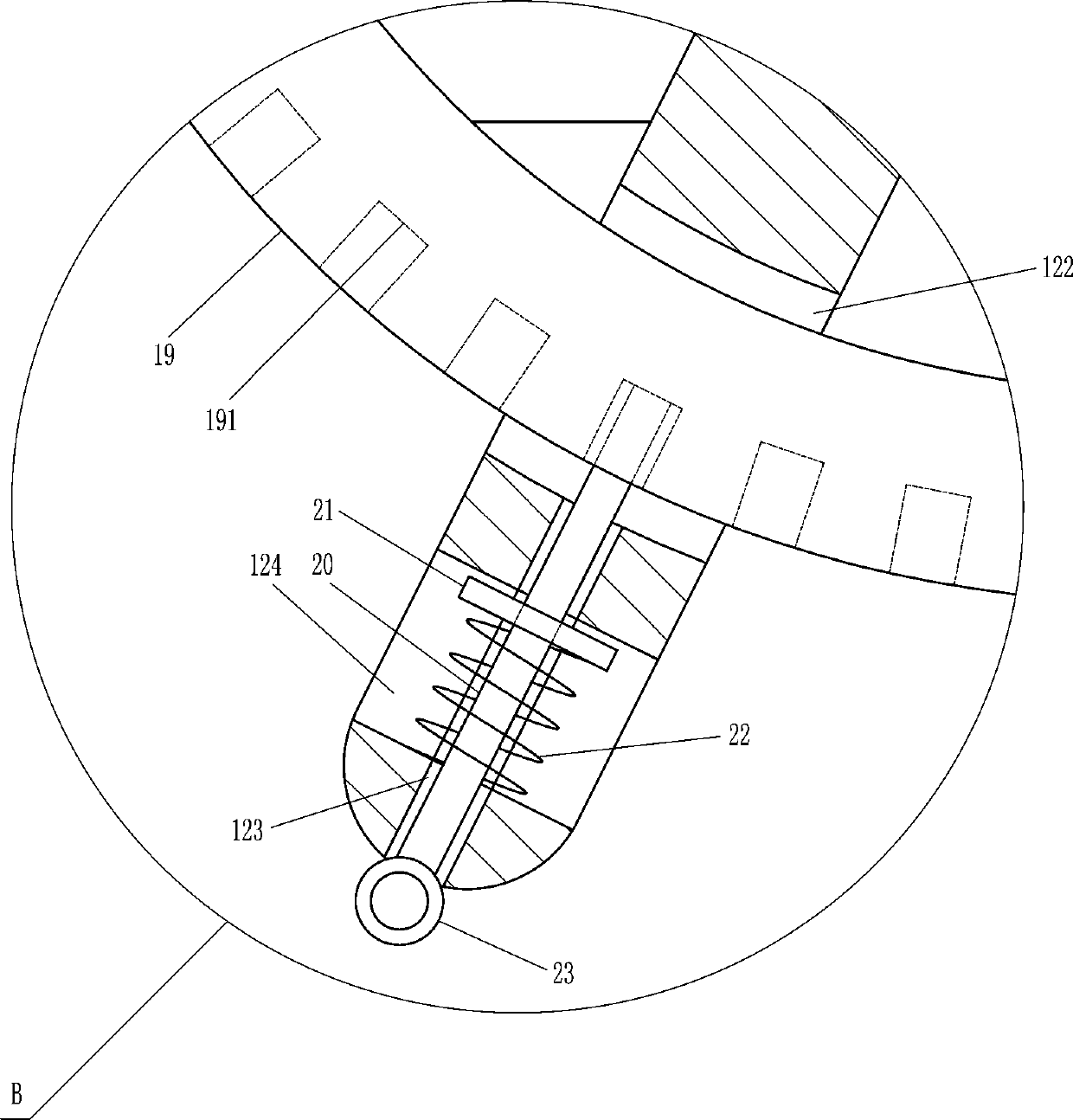

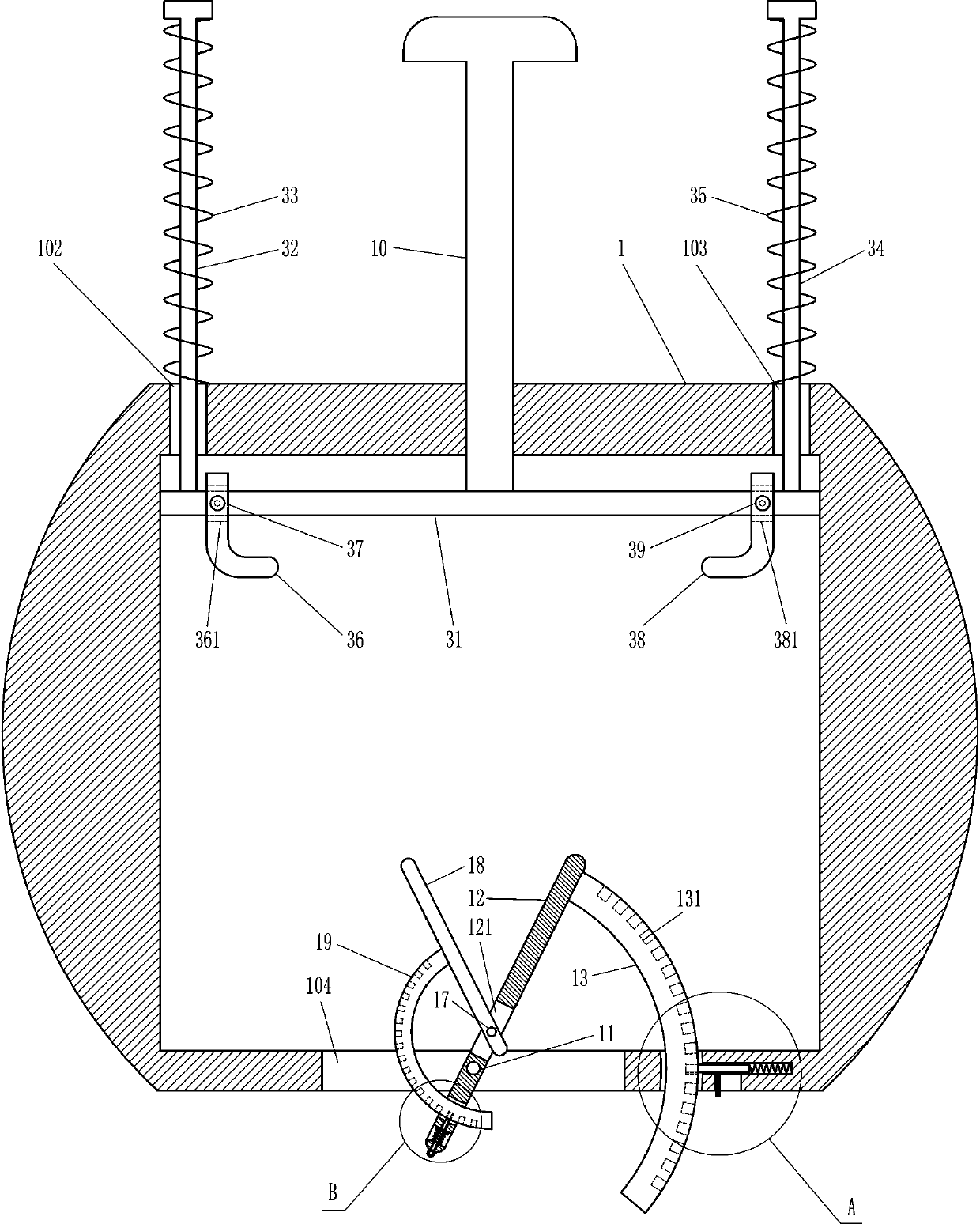

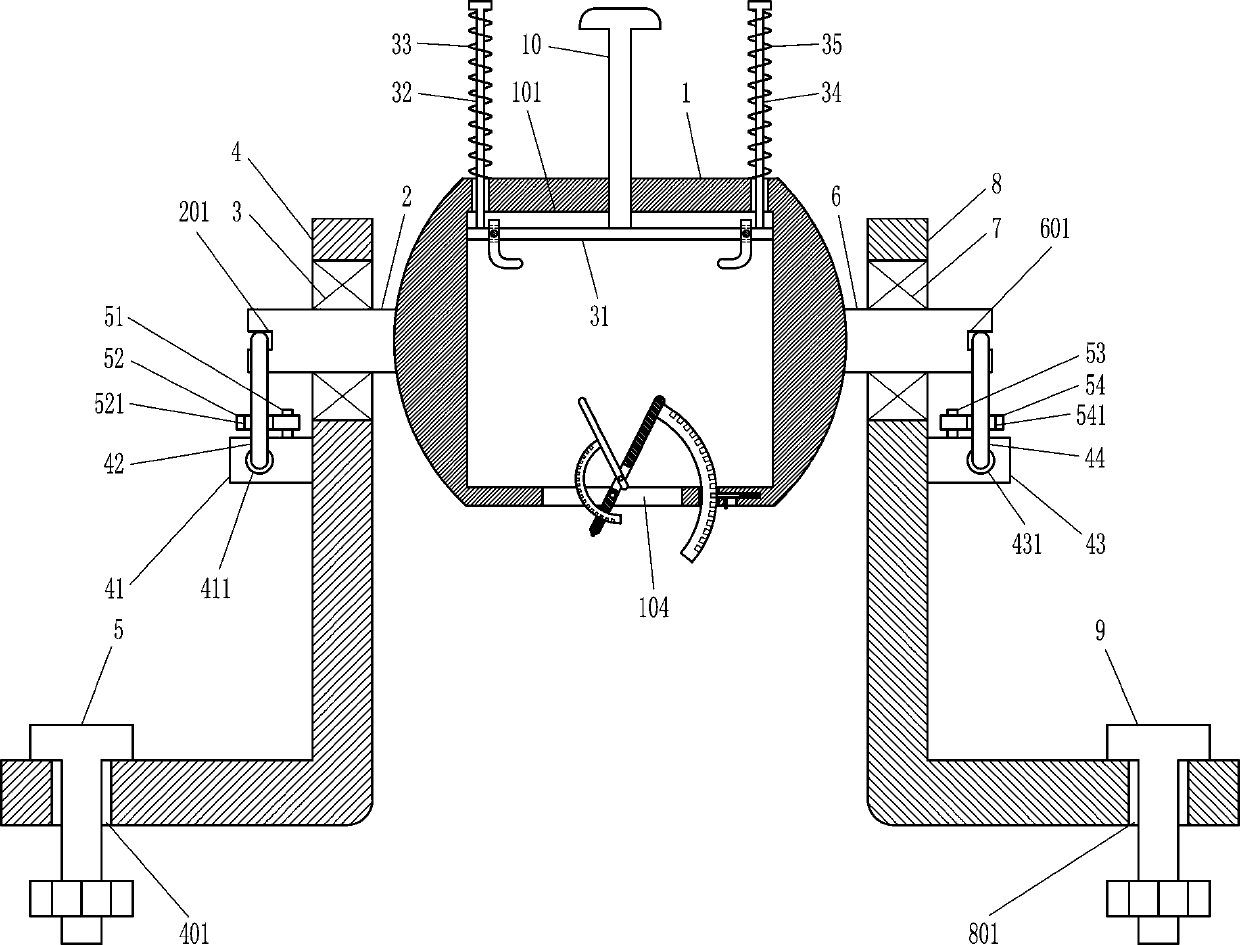

[0017] An easy-to-use triangular workholding device for CNC machining centers, such as Figure 1-4As shown, it includes a large movable plate 1, a first large rotating shaft 2, a first large bearing 3, a first large L-shaped plate 4, a first large bolt 5, a second large rotating shaft 6, a second large bearing 7, The second large L-shaped plate 8, the second large bolt 9, the large screw rod 10, the first rotating shaft 11, the large swing plate 12, the large arc guide plate 13, the large insertion rod 14, the large spring 15, the large shift lever 16, The second rotating shaft 17, the small swing plate 18, the small arc-shaped guide plate 19, the small insertion rod 20, the small baffle plate 21, the small spring 22 and the pull ring 23, the large movable plate 1 has a large rectangular groove 101 that runs through the front and back, The top of the large movable plate 1 has a first guide hole 102 and a second guide hole 103 extending downwards, the first guide hole 102 is lo...

Embodiment 2

[0019] An easy-to-use triangular workholding device for CNC machining centers, such as Figure 1-4 As shown, it includes a large movable plate 1, a first large rotating shaft 2, a first large bearing 3, a first large L-shaped plate 4, a first large bolt 5, a second large rotating shaft 6, a second large bearing 7, The second large L-shaped plate 8, the second large bolt 9, the large screw rod 10, the first rotating shaft 11, the large swing plate 12, the large arc guide plate 13, the large insertion rod 14, the large spring 15, the large shift lever 16, The second rotating shaft 17, the small swing plate 18, the small arc-shaped guide plate 19, the small insertion rod 20, the small baffle plate 21, the small spring 22 and the pull ring 23, the large movable plate 1 has a large rectangular groove 101 that runs through the front and back, The top of the large movable plate 1 has a first guide hole 102 and a second guide hole 103 extending downwards, the first guide hole 102 is l...

Embodiment 3

[0022] An easy-to-use triangular workholding device for CNC machining centers, such as Figure 1-5As shown, it includes a large movable plate 1, a first large rotating shaft 2, a first large bearing 3, a first large L-shaped plate 4, a first large bolt 5, a second large rotating shaft 6, a second large bearing 7, The second large L-shaped plate 8, the second large bolt 9, the large screw rod 10, the first rotating shaft 11, the large swing plate 12, the large arc guide plate 13, the large insertion rod 14, the large spring 15, the large shift lever 16, The second rotating shaft 17, the small swing plate 18, the small arc-shaped guide plate 19, the small insertion rod 20, the small baffle plate 21, the small spring 22 and the pull ring 23, the large movable plate 1 has a large rectangular groove 101 that runs through the front and back, The top of the large movable plate 1 has a first guide hole 102 and a second guide hole 103 extending downwards, the first guide hole 102 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com