Synchronous machining locating clamp and machining method of moving scroll plate and static scroll plate

A technology of synchronous processing and positioning fixtures, applied in the field of mechanical processing, can solve the problems of poor contour processing retention, numerous processes, friction and collision, etc., and achieve the effect of maintaining consistency, reducing processes, and reducing positional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

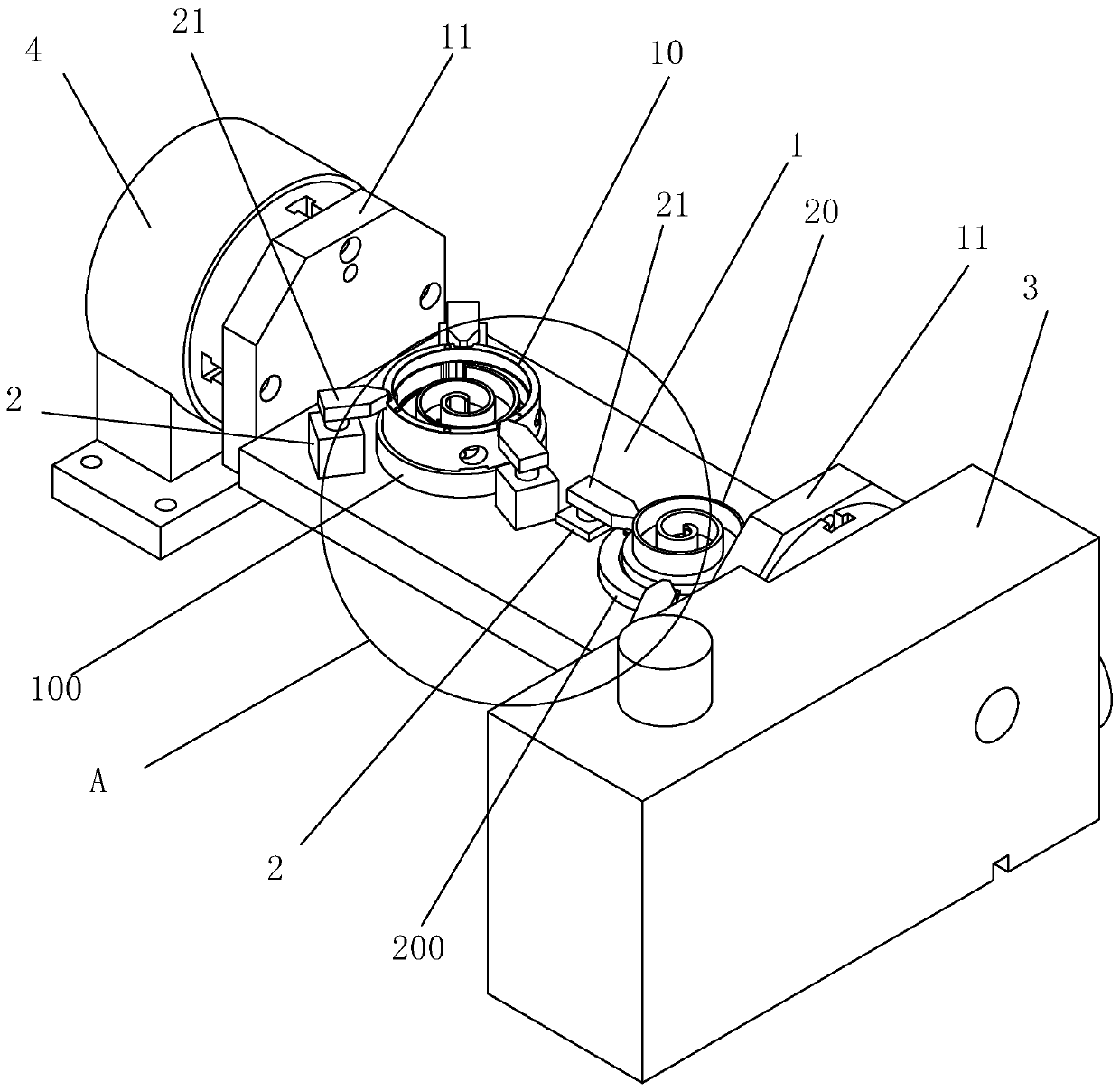

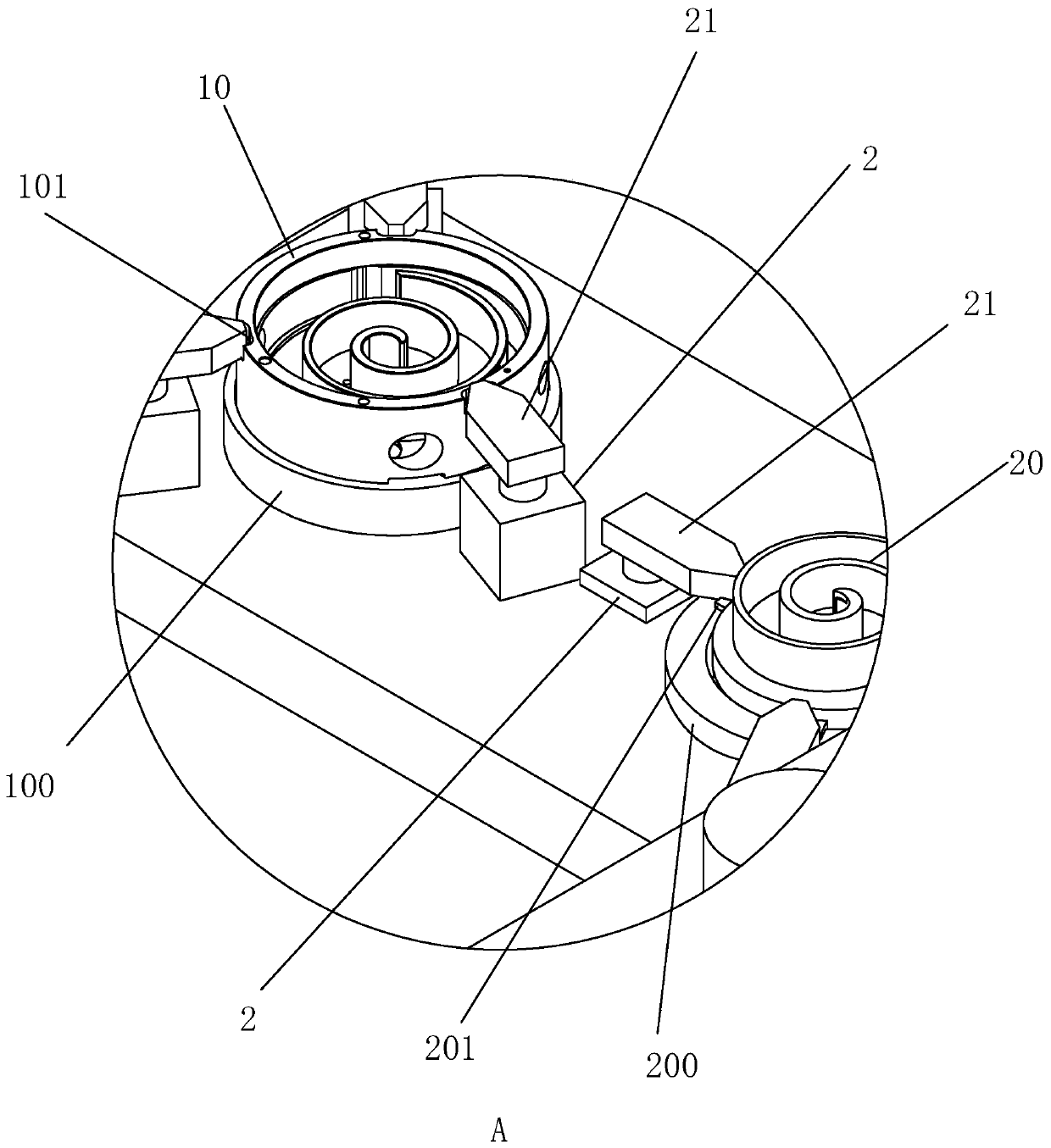

[0024] Positioning fixture for synchronous machining of movable and static scroll discs, refer to figure 1 and 2 , which includes a base plate 1, a static plate 10 and a moving plate 20 located on the base plate 1, and the base plate 1 is respectively provided with an annular static plate positioning seat 100 and a moving plate positioning seat 200 for positioning the bottom of the static plate 10 and the moving plate 20 . The bottom plate 1 is located at the static disk positioning seat 100 and the moving disk positioning seat 200. Each annular array is provided with at least three pressure cylinders 2, preferably three. The pressure cylinders 2 are oil cylinders, and the pistons of the pressure cylinders 2 are provided. Corresponding to the pressing block 21 of the scroll disk; the bottom plate 1 , the positioning seat 100 of the static disk and the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com