Process for producing contacts on electrical components suitable for flip-chip assemble

A technology of electrical components and flip-chip method, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., and can solve problems such as enlargement and finger structure short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

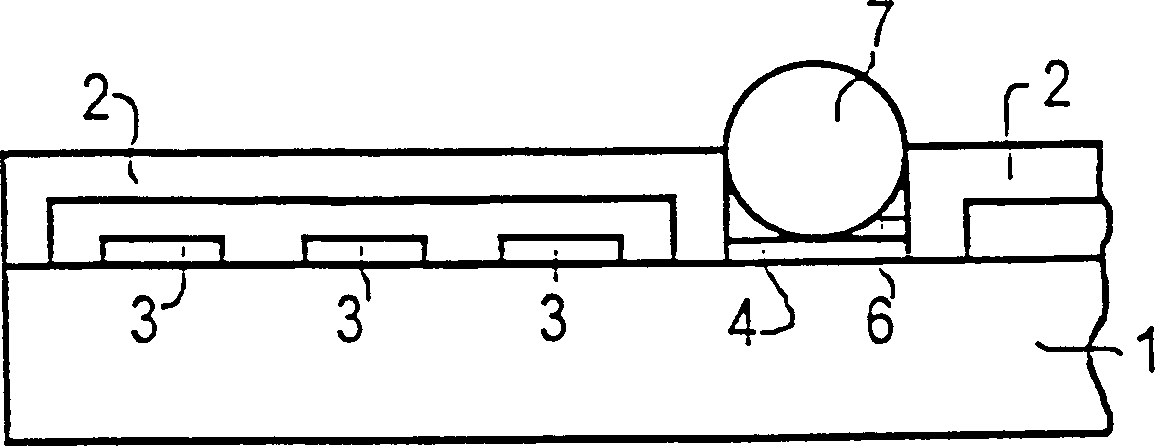

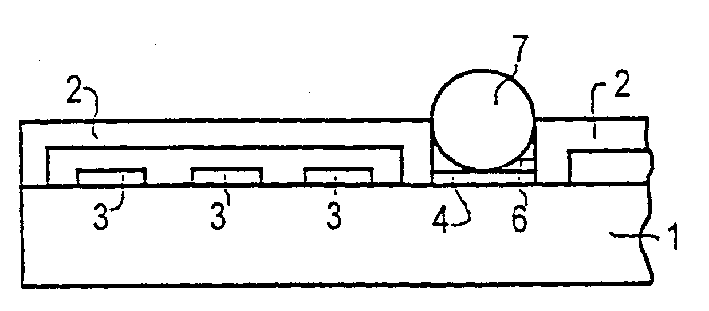

[0014] according to figure 1 An OFW element generally consists of a piezoelectric substrate 1 and conductive structures 3 arranged thereon, wherein finger electrodes such as interdigital transducers, resonators or reflectors are involved. As described in the earlier German patent entry mentioned at the outset, the conductive structure 3 is covered by a cover layer 3, which protects the structure from environmental influences, while the element with the cover layer 2 and the substrate 1 as "housing" can directly into use.

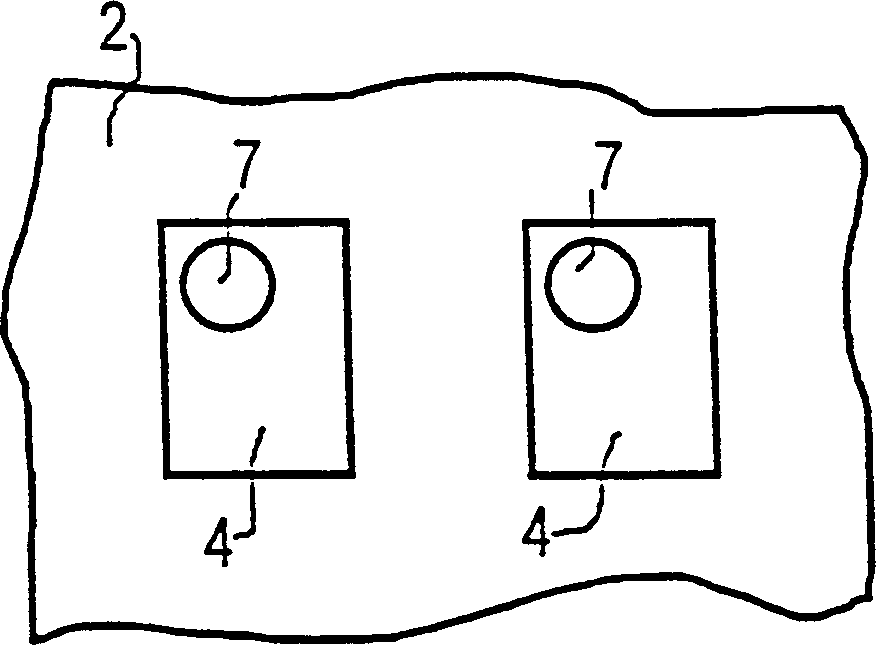

[0015] Contacts suitable for flip-chip assembly are designed according to the invention for making electrical contact with the conductive structure 3 . Such as figure 1 It can be clearly seen from the illustration that an opening 6 is provided in the cover layer 2, through which the solderable layer 4 is applied, which is in contact with the connection surface (solder pad) (not shown) of the conductive structure 3 . Such as figure 2 It is clearly shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com