A repair and caulking vehicle for building crack construction

A construction and body technology, which is applied in the field of repairing and caulking vehicles for building crack construction, can solve the problems of long age of the house, uneven repair of cracks, waste of workers' time and energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

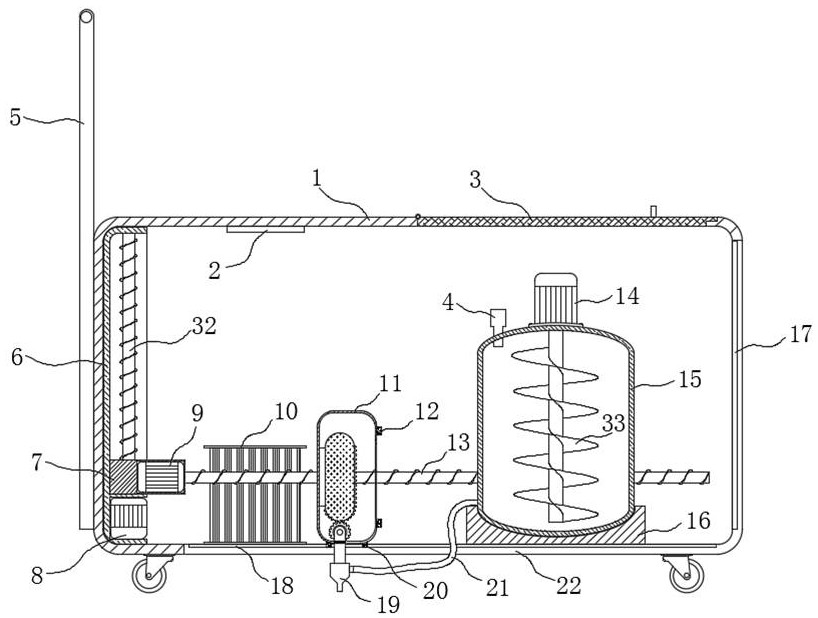

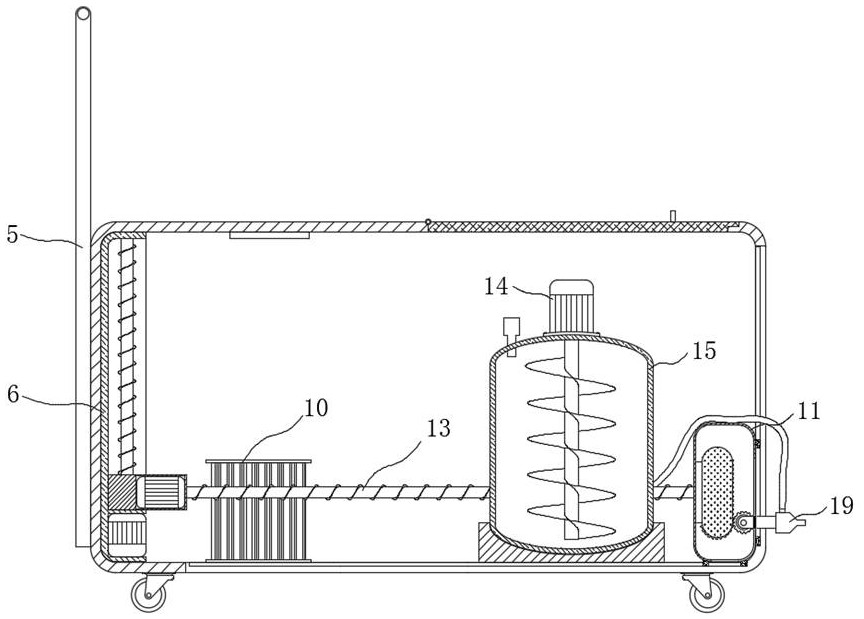

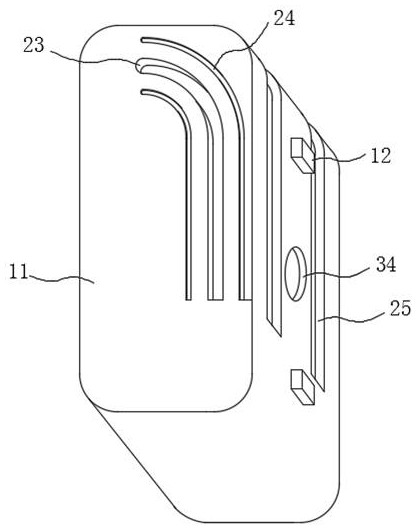

[0033] refer to Figure 1-5 As shown, a repairing and caulking vehicle for building crack construction includes a body 1, the inside of which is a hollow structure, a lifting mechanism and a stirring mechanism are installed in the body 1, and a horizontal driving mechanism is installed on the lifting mechanism , a moving mechanism is installed on the horizontal drive mechanism, a controller 2 is installed on the inner top wall of the body 1, a battery 10 is installed on the inner bottom wall of the body 1, and the controller 2 and the battery 10 are Electrically connected; the bottom surface of the body 1 and one of the side walls of the body 1 are jointly provided with two limiting rails 22, the output end of the moving mechanism passes through the limiting rails 22 and is equipped with a discharge seat 19, so A push frame 5 is installed on the outer wall of the body 1, four universal wheels are installed on the bottom surface of the body 1, and the upper end surface of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com