Method for preparing sample used for large-scale in-situ high-pressure seepage deformation test

An osmotic deformation, in situ technique used in sample preparation for testing, permeability/surface area analysis, sampling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

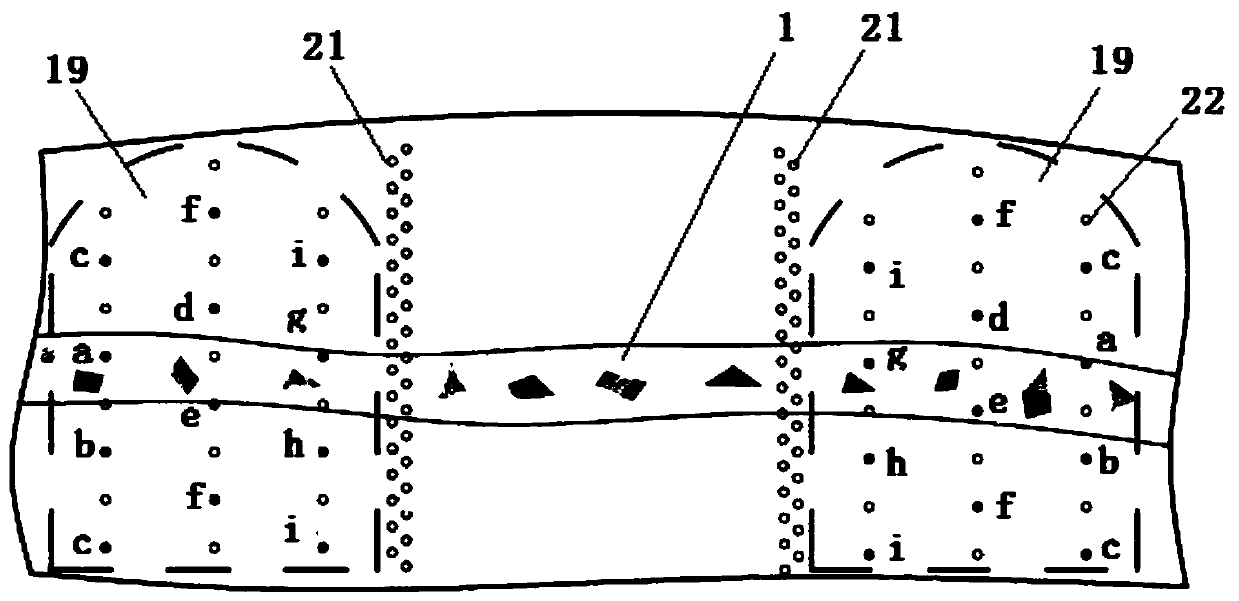

[0040] A method for preparing a large-scale in-situ high-pressure osmotic deformation test sample according to an embodiment of the present invention. This embodiment takes a slow-dipping interlayer slip zone as an example to describe the method in detail.

[0041] The method comprises the steps of:

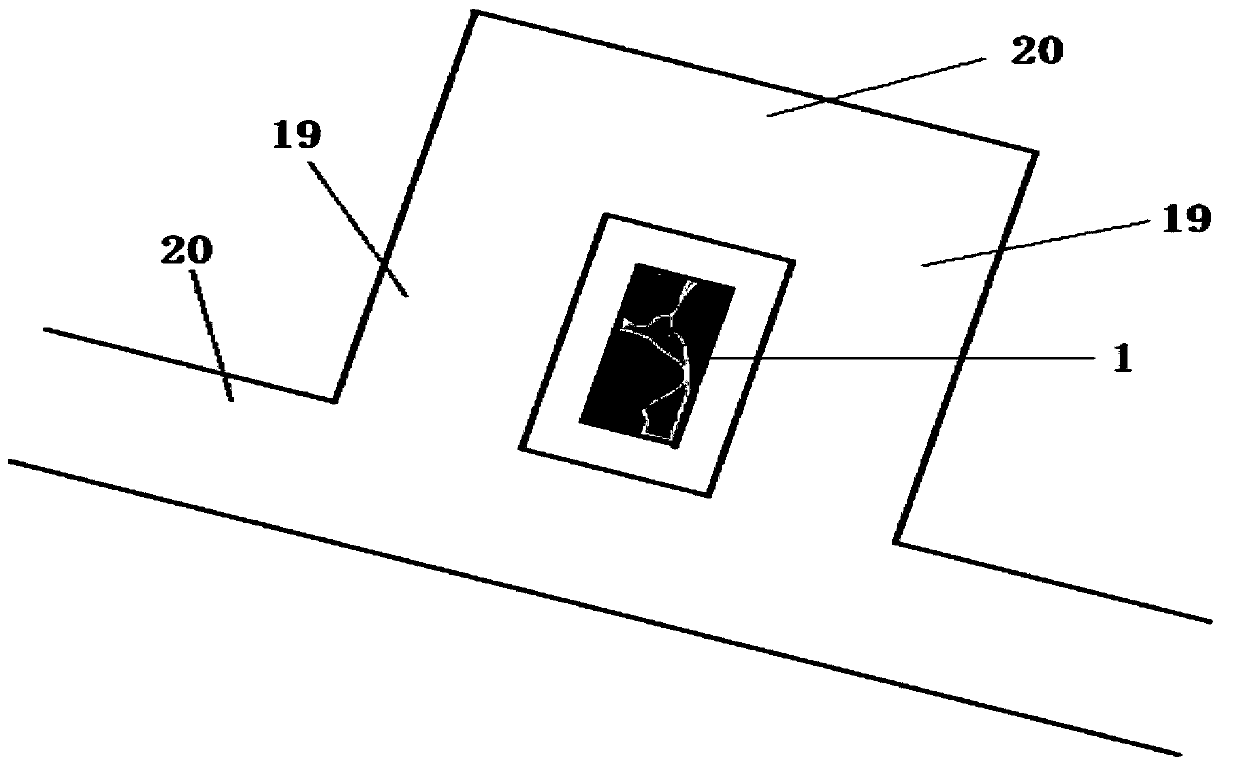

[0042] Step 1: Blasting of branch holes 19 and connecting holes 20, opening a hole 19 on both sides of the position of the selected in-situ sample 1 on the wall of the main hole 18, between the tails of the two branch holes 19 along the direction of the weak structure The connecting hole 20 is opened, and the same blasting method is adopted when the branch hole 19 and the connecting hole 20 are opened.

[0043] figure 1 It is a schematic diagram of the structure of the branch hole 19 and the connecting hole 20. The two branch holes 19 are drille...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com