Inertia wheel energy-storage friction nanogenerator of multi-sleeve structure based on differential transmission

A nano-generator and differential transmission technology, which is applied to friction generators, engines, machines/engines, etc., can solve the problems of insufficient running time, low power generation frequency, and small power generation, and achieve compact structure and high power generation frequency , the effect of increasing working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

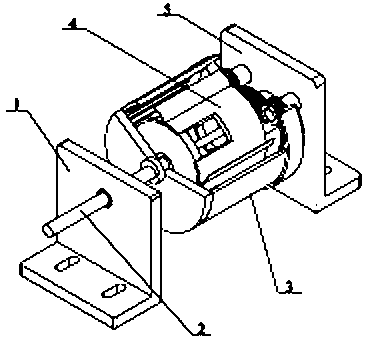

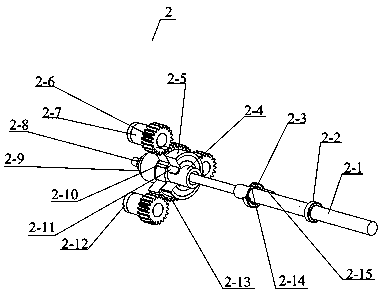

[0030] Specific implementation method: combined Figure 1~Figure 17 Describe this embodiment. This embodiment provides a specific implementation of an inertial wheel energy storage type friction nanogenerator based on a differential transmission multi-sleeve structure. The specific implementation of the nanogenerator is expressed as follows:

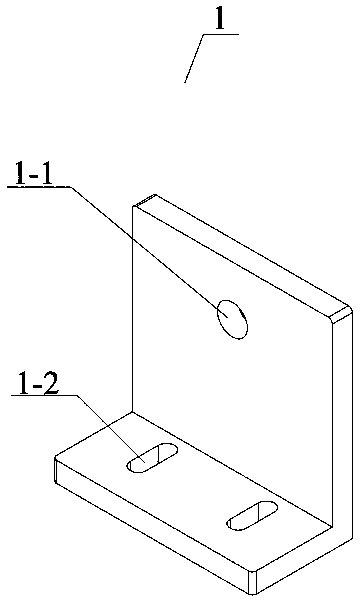

[0031] The inertia wheel energy storage friction nanogenerator based on differential transmission multi-sleeve structure includes support base I1, transmission assembly 2, outer cylinder assembly 3, inner cylinder assembly 4 and support base II5; transmission assembly 2 is installed on support base I1 and the supporting seat II5; the outer cylinder assembly 3 and the inner cylinder assembly 4 are installed on the transmission assembly 2, and the rotation direction of the outer cylinder assembly 3 and the inner cylinder assembly 4 is opposite.

[0032] The support seat I1 is provided with a main shaft bearing installation hole I1-1 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com