Method for avoiding residual glue at stepped position of stepped plate

A step board and residual glue technology, which is applied in multi-layer circuit manufacturing, secondary treatment of printed circuit, electrical components, etc., can solve the problems of long time-consuming high-temperature resistant tape, difficult operation, easy damage of step board, etc., and achieves convenience Fast processing, high coverage accuracy, flatness protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

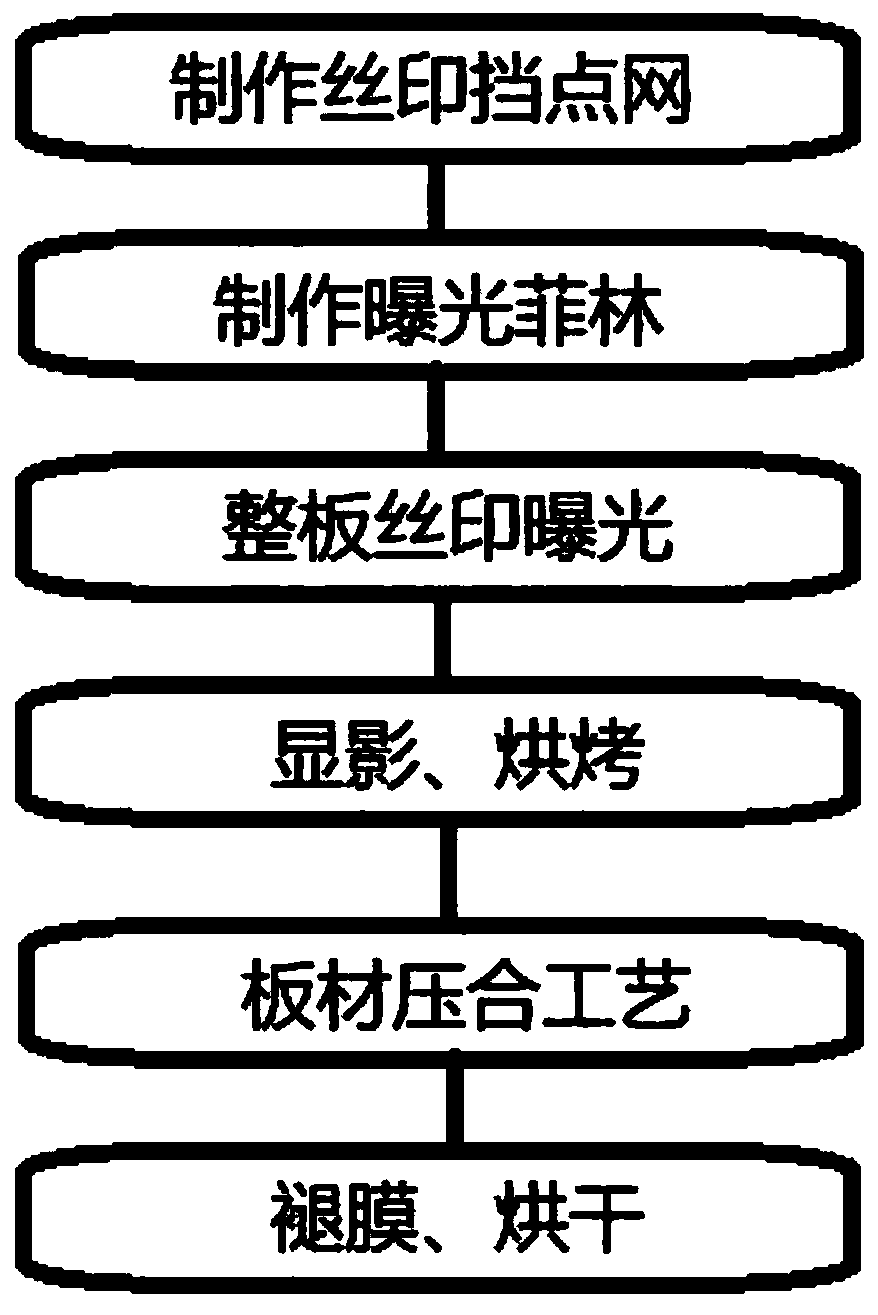

[0023] Such as figure 1 As shown in , an embodiment of the present invention provides a method for preventing residual glue at the step position of the step plate, including the following steps:

[0024] S1. Make a screen printing dot net, and set the printing oil area on the surface of the step plate to prevent residual glue;

[0025] S2. Make the exposure film, according to the D-10mil step area;

[0026] S3. The whole board is exposed to silk screen printing, and the oil layer covered by the position of preventing the residual glue is cured by exposure;

[0027] S4, developing, washing off the oil layer of the non-exposed part by liquid medicine;

[0028] S5, baking, the wet film formed by curing the oil layer by baking;

[0029] S6. Pressing the boards, performing a pressing process on the stepped boards according to the requirements of the board making, using the prepreg or prepreg powder as the medium for pressing to obtain a laminated board;

[0030] S7, open the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com