Device for correcting pre-tightening force between firing pin and nozzle and piezoelectric injection valve thereof

A piezoelectric spraying and preloading force technology, which is applied to the device and coating of the surface coating liquid, which can solve the problems of affecting the dispensing accuracy, easy deviation of the preloading force, and difficult to grasp the nozzle installation position. , to achieve the effect of improving maintenance efficiency and reducing assembly difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

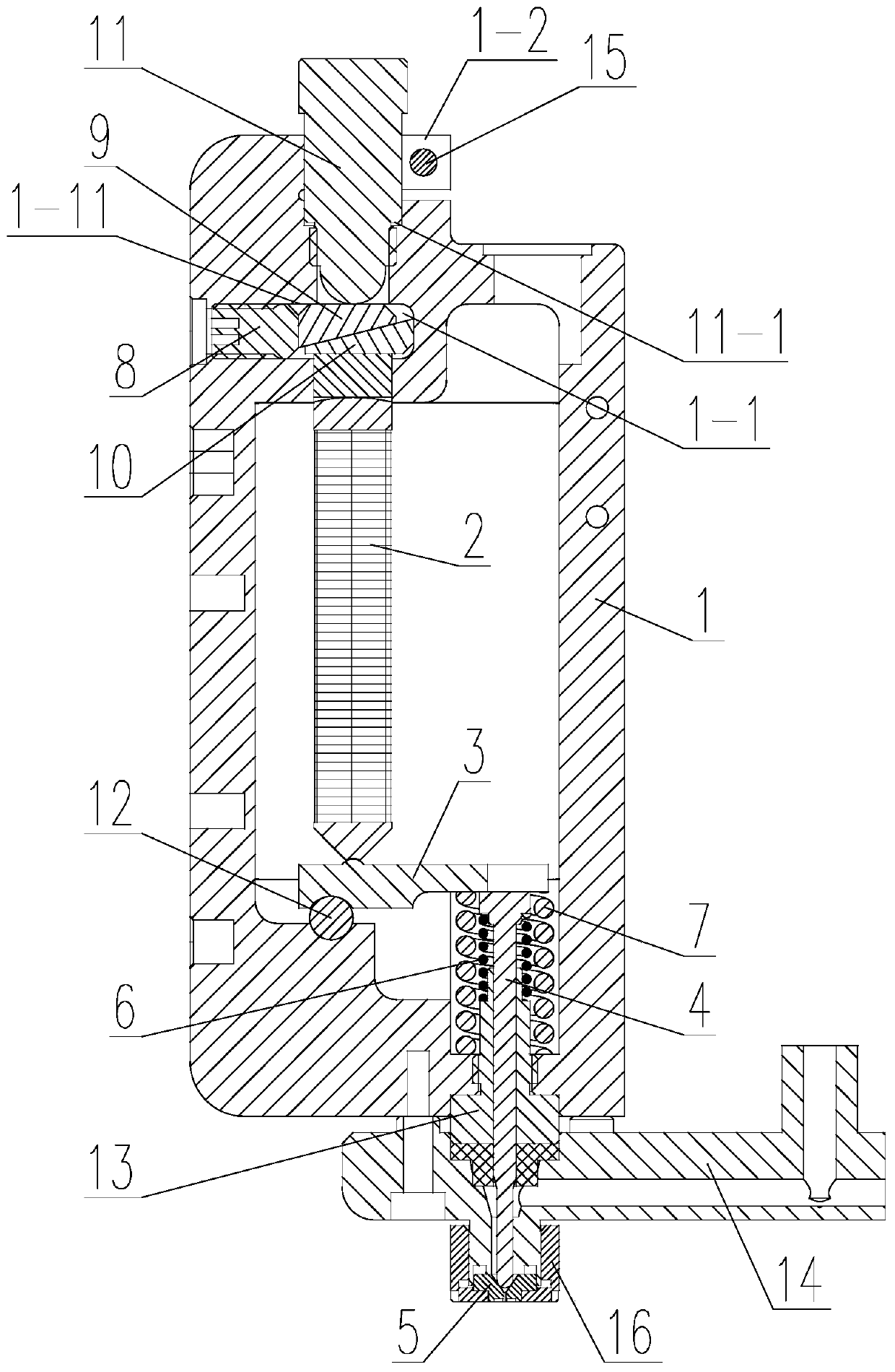

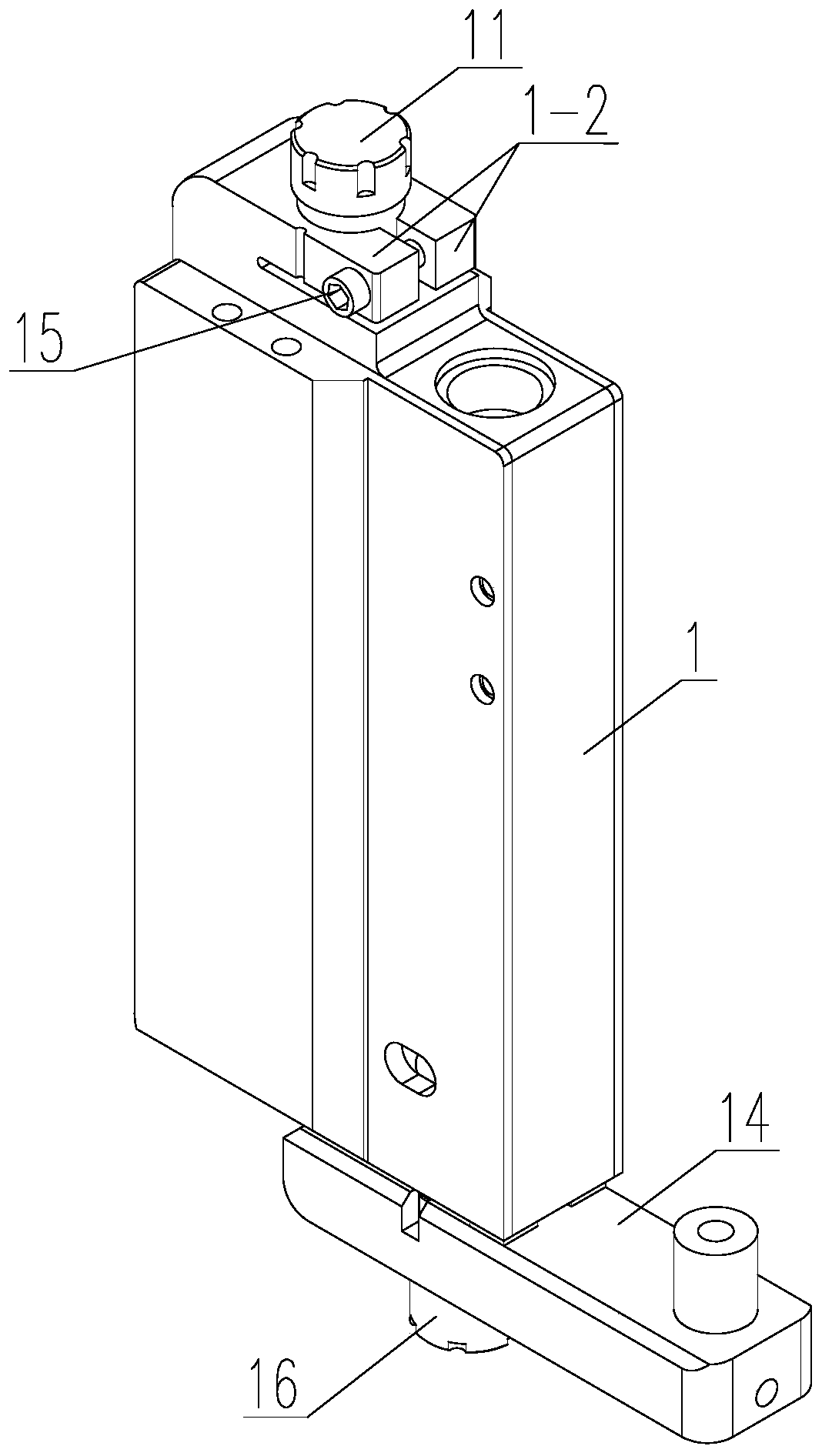

[0028] Such as Figure 1-2 As shown, a device for correcting the pre-tight force between the striker and the nozzle is used for correcting the pre-tight force between the striker and the nozzle, which is used for a piezoelectric injection valve, and the piezoelectric injection valve includes a valve body 1, The piezoelectric actuator 2 arranged in the valve body 1, the striker 4 slidably installed on the valve body 1 and the nozzle 5 located under the valve body 1, the piezoelectric actuator 2 amplifies the driving force through the lever 3 to drive the striker 4 Feed to the nozzle 5, the device consists of:

[0029] The first adjustment mechanism has a pretensioner 8 and an upper adjustment block 9 and a lower adjustment block 10 that cooperate with each other. The pretensioner 8 is limited on the side of the upper adjustment block 9 and can push the upper adjustment block from the side. 9. Make the lower adjustment block 10 drive the piezoelectric actuator 2 to move down; ...

Embodiment 2

[0048] A piezoelectric injection valve, including the device for correcting the pre-tightening force between the striker and the nozzle in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com