A method for automatically avoiding seam-marked slabs in sector segments during quick change of tundish for continuous casting machine

A sector segment and continuous casting machine technology, which is applied in the field of slab processing, can solve the problems of affecting the precision of the stick gap and the effect of the adjustment force is not obvious, so as to reduce the maintenance cost of equipment, prolong the service life of the line, and reduce the tension and straightening torque Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

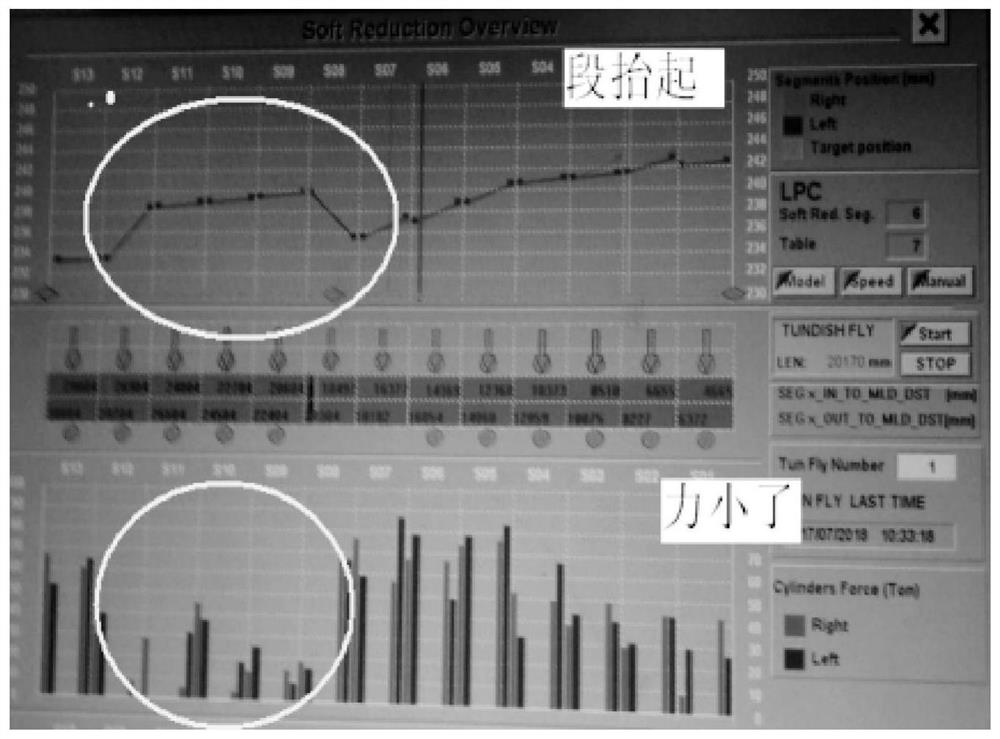

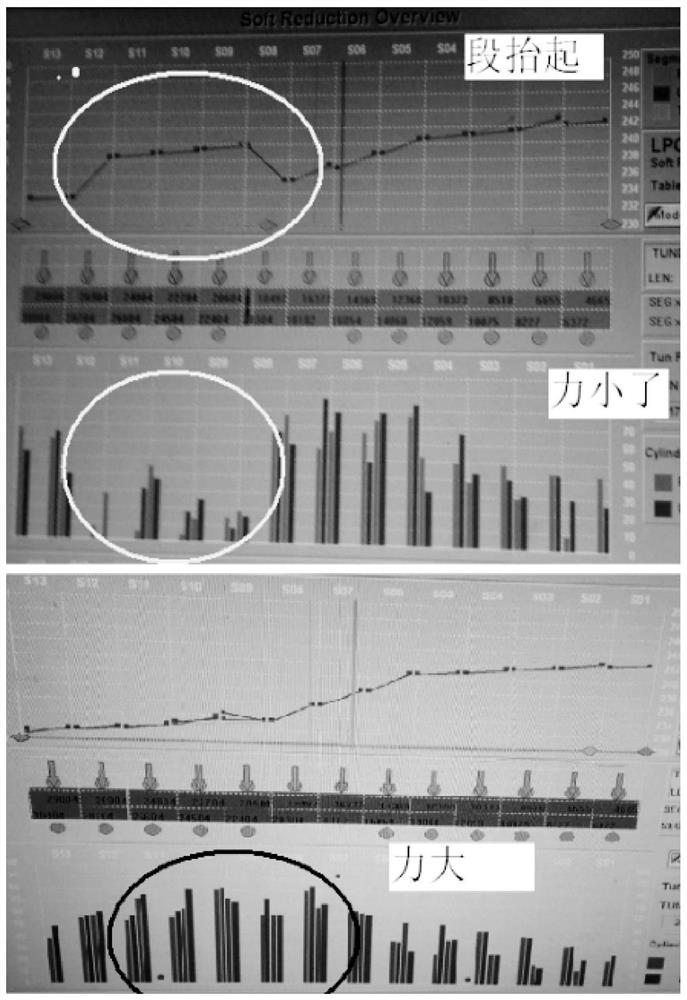

[0022] Benxi Iron and Steel Works built a 2200mm continuous casting machine on December 1, 2008. This continuous casting equipment is a first-class machine with a metallurgical length of 35.055m, an arc radius of 9.5m, a billet width of 1000-2200mm, and a billet length of 9000mm. ~11000mm. After the production test in recent months, during the lifting of the quick-change avoidance of the joint mark of the segment, it is obvious that the clamping force of the frame of the segment is much smaller than before (50% lower), and the overall tension and straightening moment is also reduced to 50%-60% left and right, such as image 3 shown.

[0023] By improving the action mode of the sector section during the quick change and lifting of the seam mark, the purpose of increasing the clamping force of the sector section frame on the slab during the quick change of the tundish is greatly avoided, the pulling and straightening torque is reduced, and the casting machine problem is solved....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com