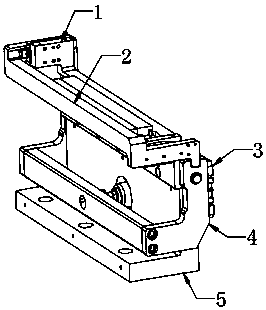

Two-square strip fixture mechanism

A fixture and strip technology, which is applied in the field of two-piece square strip fixture mechanism, can solve the problems of poor clamping and processing of square strips, inconvenient square strip clamping and processing, and inconsistent processing accuracy, etc., to achieve improved clamping Convenient holding, good clamping effect and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

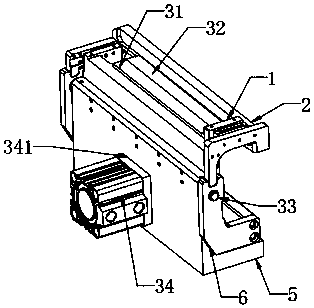

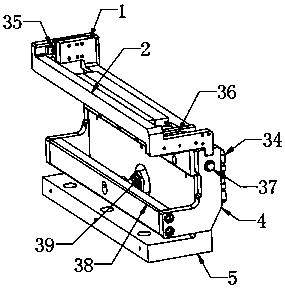

[0023] Specific implementation method: the user first pushes the first square strip 31 and the second square strip 32 into the inside of the moving fixture 2 when the cylinder 34 is in the state of opening the moving fixture, and then pushes the push button, and the cylinder 34 works to push out, and the cylinder 34 Push out to the left through the floating joint 39, the floating joint 39 drives the push rod 38 to push out to the left, the push rod 38 drives the left lever 6 and the right lever 4 to move to the left, and the left lever 6 and the right lever 4 rotate through the left shaft 33 and the right shaft 37 , the left lever 6 and the right lever 4 stir the moving fixture 2 to move to the right through the left guide rail 35 and the right guide rail 36, and the moving fixture 2 clamps the first square strip material 31 and the second square strip material 32, which improves the present invention. clamping convenience.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com