Connecting rod assembly for piston type compressor

A technology of connecting rod assembly and compressor, which is applied in the direction of variable capacity pump components, liquid variable capacity machinery, pump components, etc. Improved accuracy, novel structure, and improved matching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

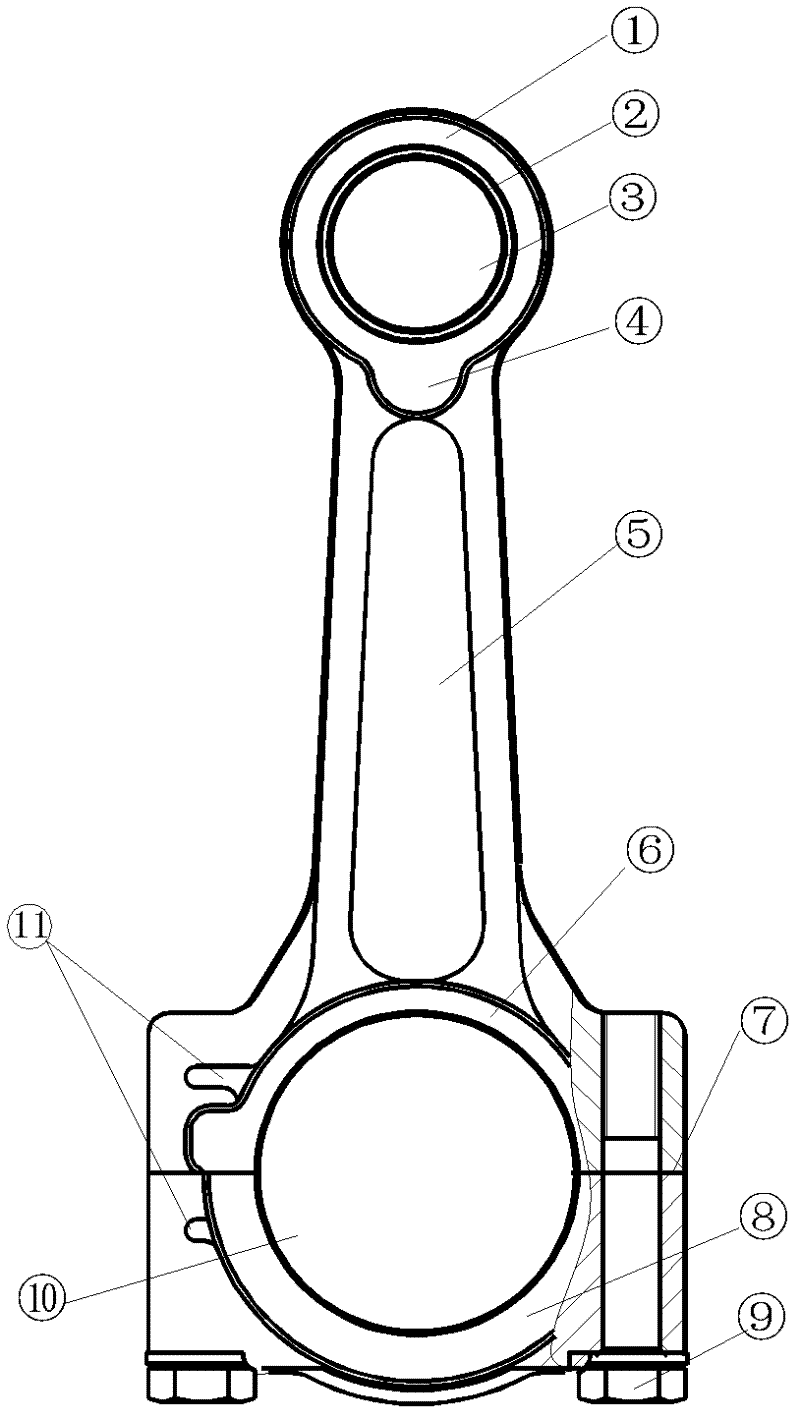

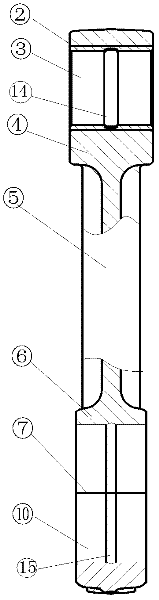

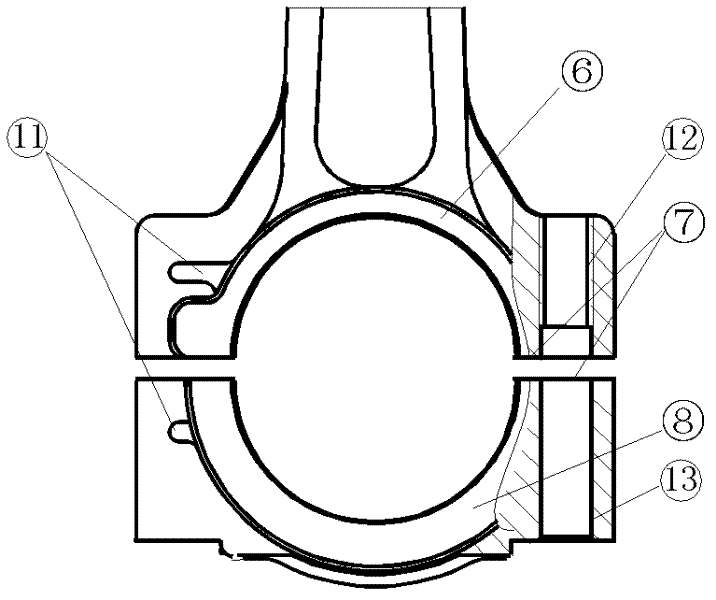

[0029] The specific embodiment of the present invention is shown in the attached drawings, which is composed of a connecting rod small head 1, a small head ring 2, a shaft 5 and a connecting rod large end device; it is characterized in that one end of the shaft 5 is processed with a connecting rod Small head 1; Small head bushing ring 2 is press-fitted on small shaft hole 3 of small connecting rod 1; Small head boss 4 is processed at the connection between small head 1 and shaft 5; Large connecting rod device adopts Split structure, flat cut 7 divides it into connecting rod big end seat 6 and big end cap 8. The connecting rod big end seat 6 is machined with threaded hole 12, and the big end cap 8 is machined with a positioning hole 13 concentric with the threaded hole 12, and They are connected by positioning bolts 9; the connecting rod big end seat 6 and the shaft 5 are processed into one body; the connecting rod big end seat 6 and the big end cover 8 are each cast with a direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com