Production site potential safety hazard monitoring method

A technology for hidden safety hazards and construction sites, which is applied in computer security devices, digital data protection, and other database retrieval to achieve effective monitoring and facilitate statistical query.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

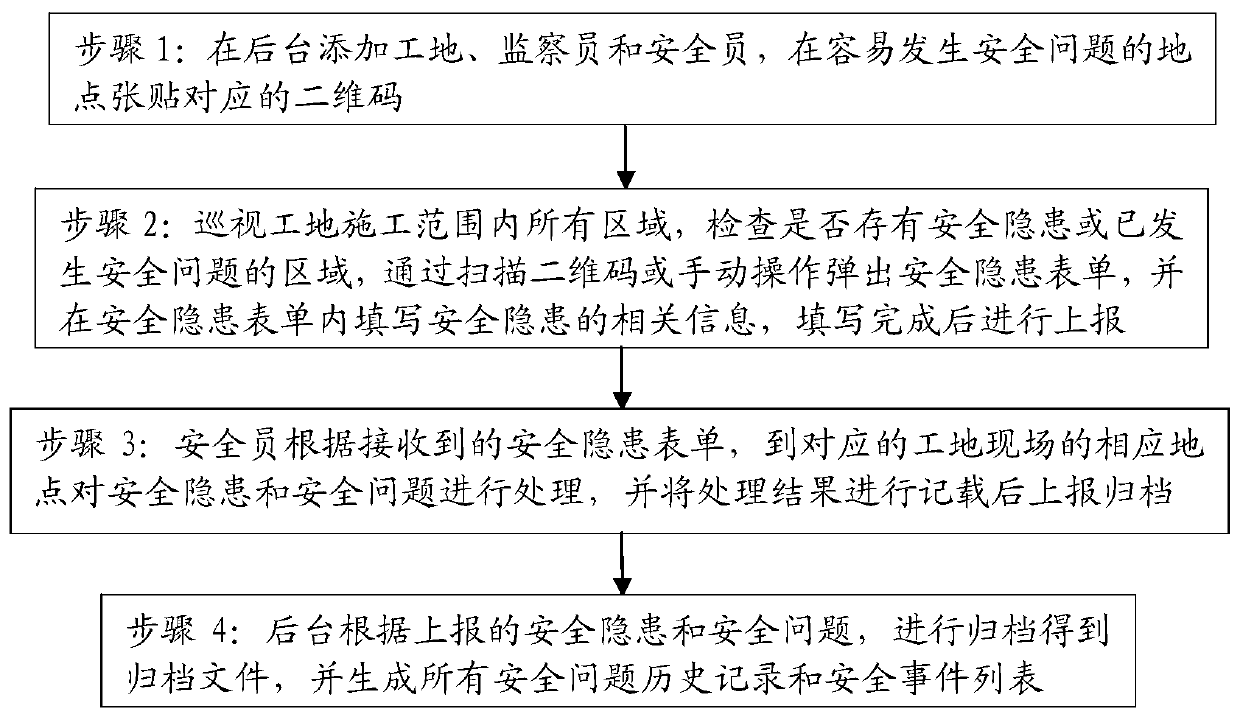

[0021] Such as figure 1 As shown, a production site safety hazard monitoring method includes the following steps:

[0022] Step 1: The administrator adds construction sites, inspectors and safety officers in the background (server), and determines the construction scope of each construction site. The construction scope of the construction site can be determined according to the designed construction drawings, or determined through on-site surveys. Add safety-prone points to the corresponding locations within the construction scope of each construction site, and generate corresponding QR codes, and post the QR codes on corresponding locations on the construction site, that is, the QR codes include geographical locations where safety problems are prone to occur information.

[0023] Each administrator manages several supervisors, safety officers and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com