Semiconductor packaging mold and packaging technology thereof

A semiconductor and mold technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of incomplete protection of semiconductor chips, inability to meet the rapid positioning of semiconductor chips of different sizes, etc., to facilitate heat dissipation and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

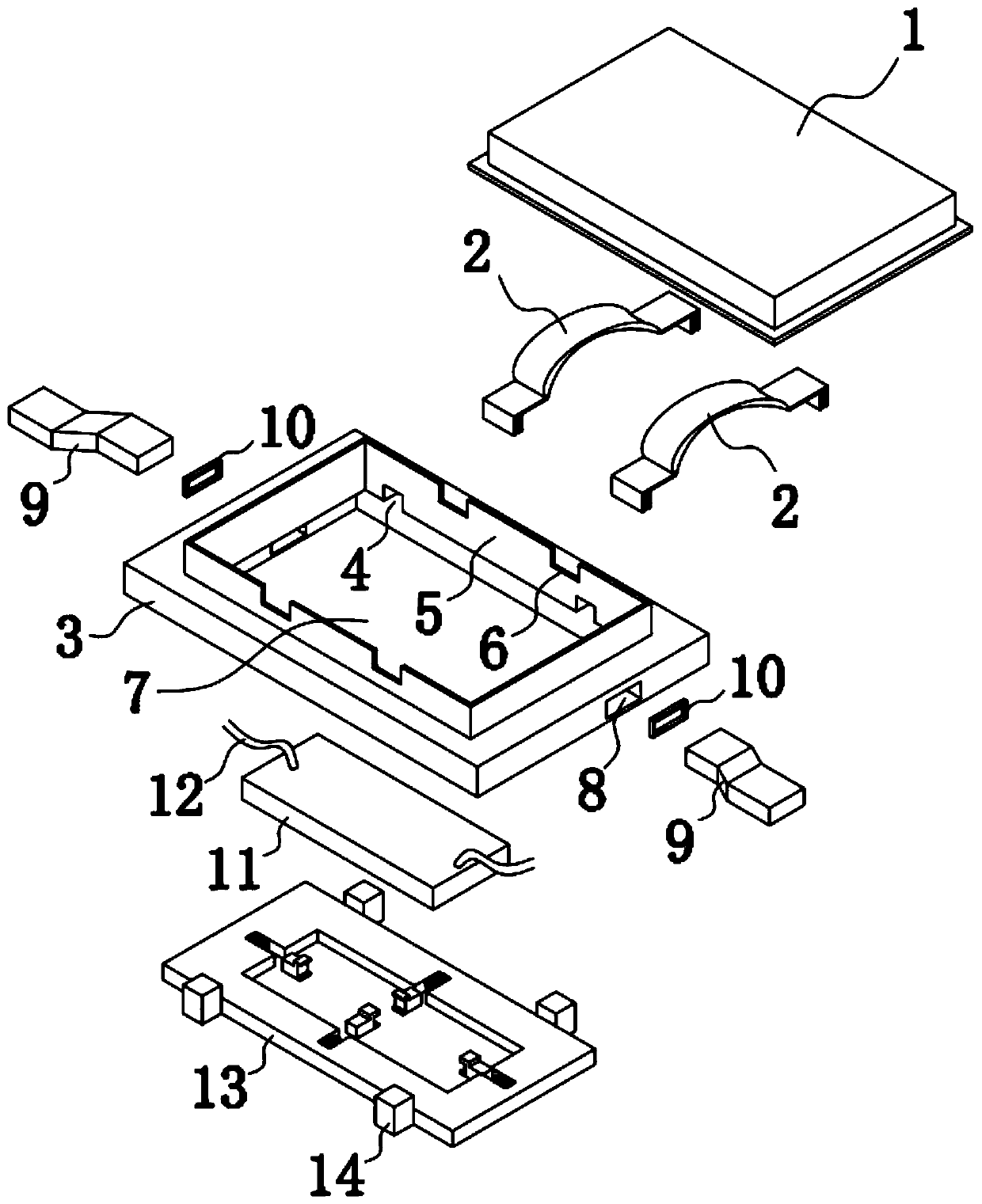

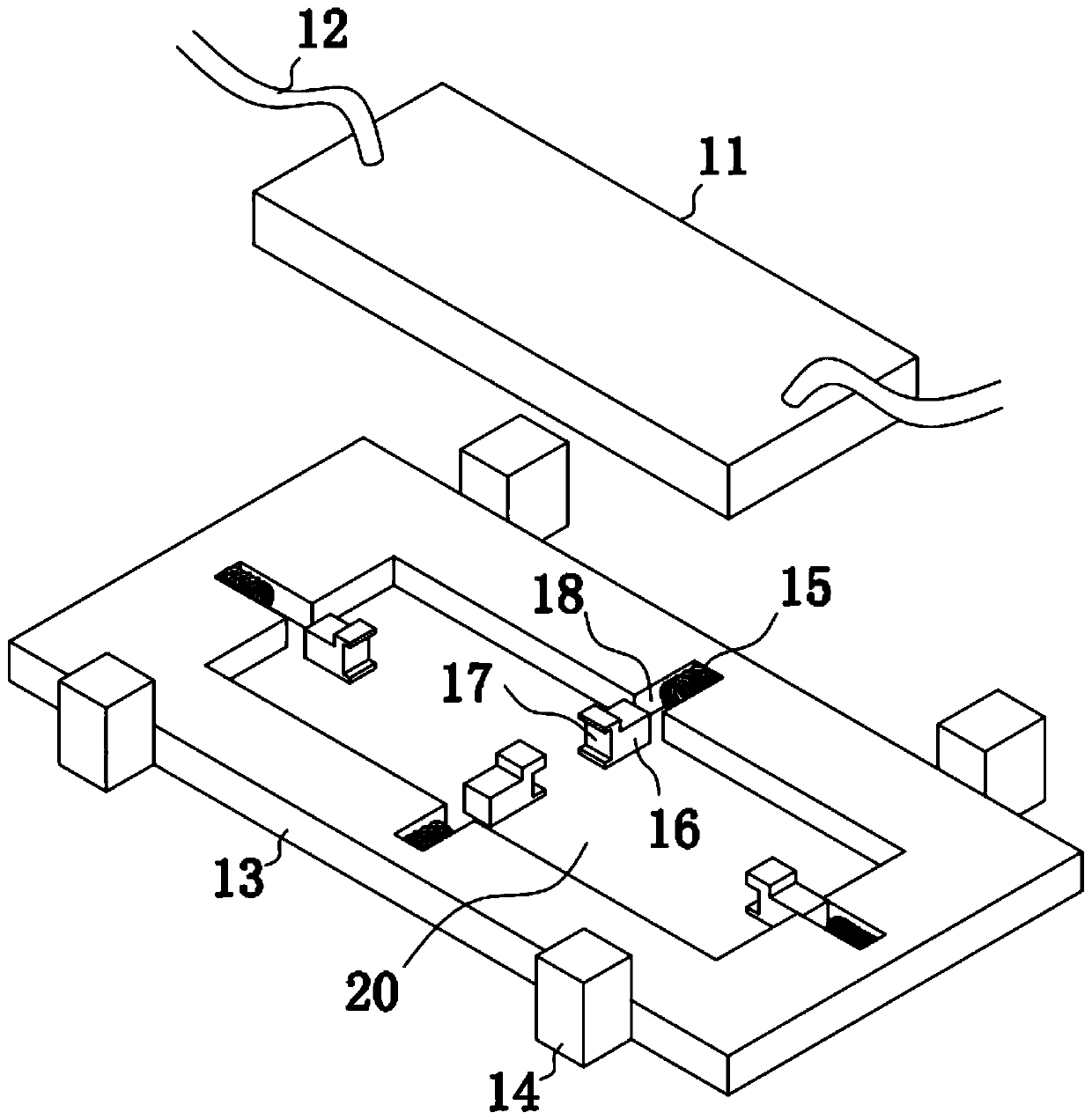

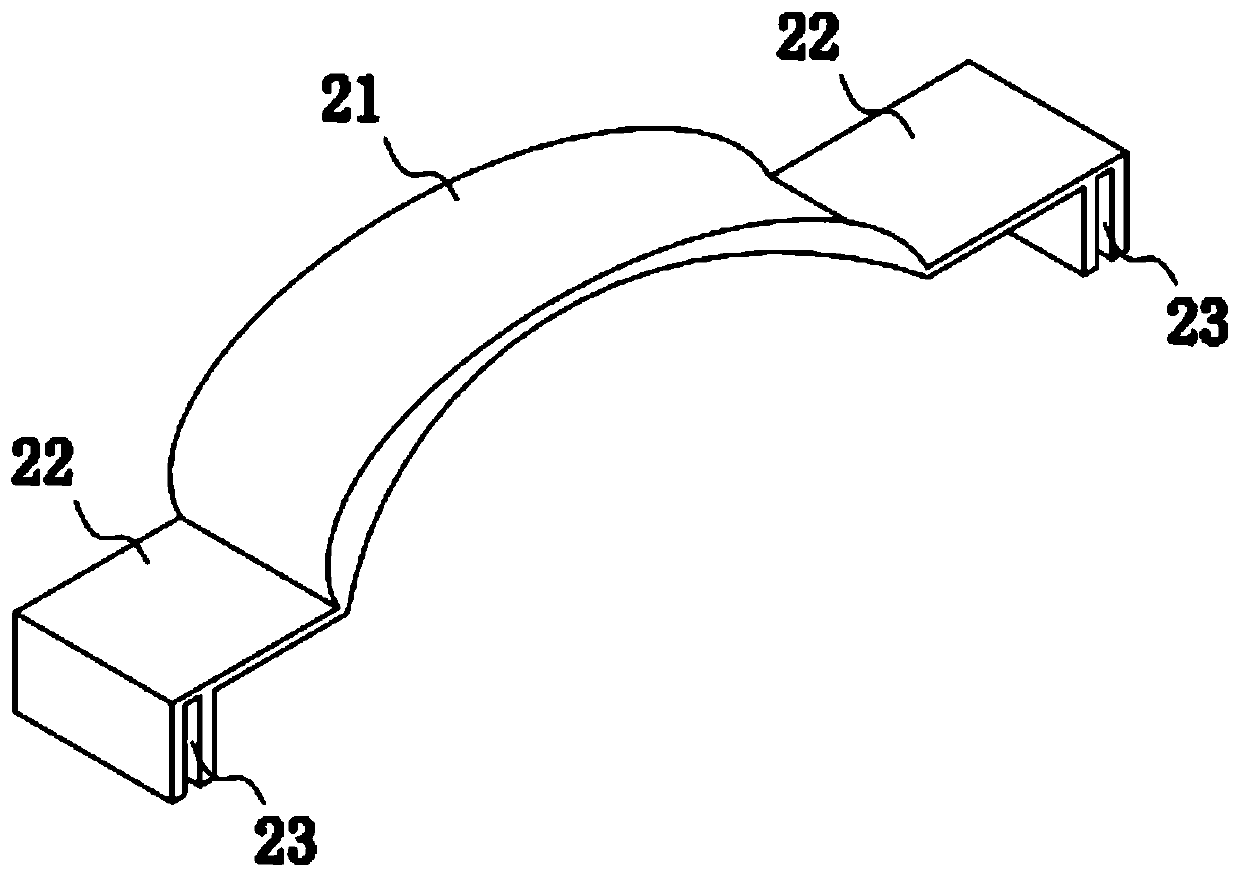

[0024] The present invention provides such Figure 1-4 A semiconductor package mold, comprising a semiconductor chip 11 and a mounting plate 3, the semiconductor chip 11 is arranged in the mounting groove 20 on the upper end of the substrate 13, and fixed by a clamping mechanism in the mounting groove 20, the mounting plate 3 The middle part of the opening groove 7 is provided with an opening groove 7, the upper end of the opening groove 7 is provided with a protective ring 5, the lower end of the mounting plate 3 is provided with a positioning groove 4, and the positioning protrusion 14 on the side of the substrate 13 is snapped into the positioning In the groove 4, pins 9 are connected to the sockets 8 at both ends of the mounting plate 3, and one end of the pins 9 extending into the opening groove 7 is connected to the semiconductor chip 11 through a lead wire 12, and the protective ring 5 There are two sets of transverse support mechanisms 2 connected between the front and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com