Rotor Internally Cooled Pulse Generator

A generator and rotor technology, which is applied in the field of rotor internally cooled pulse generators, can solve problems such as rotor cooling difficulties, achieve the effects of increasing power density and power level, reducing transient temperature rise, and improving discharge capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

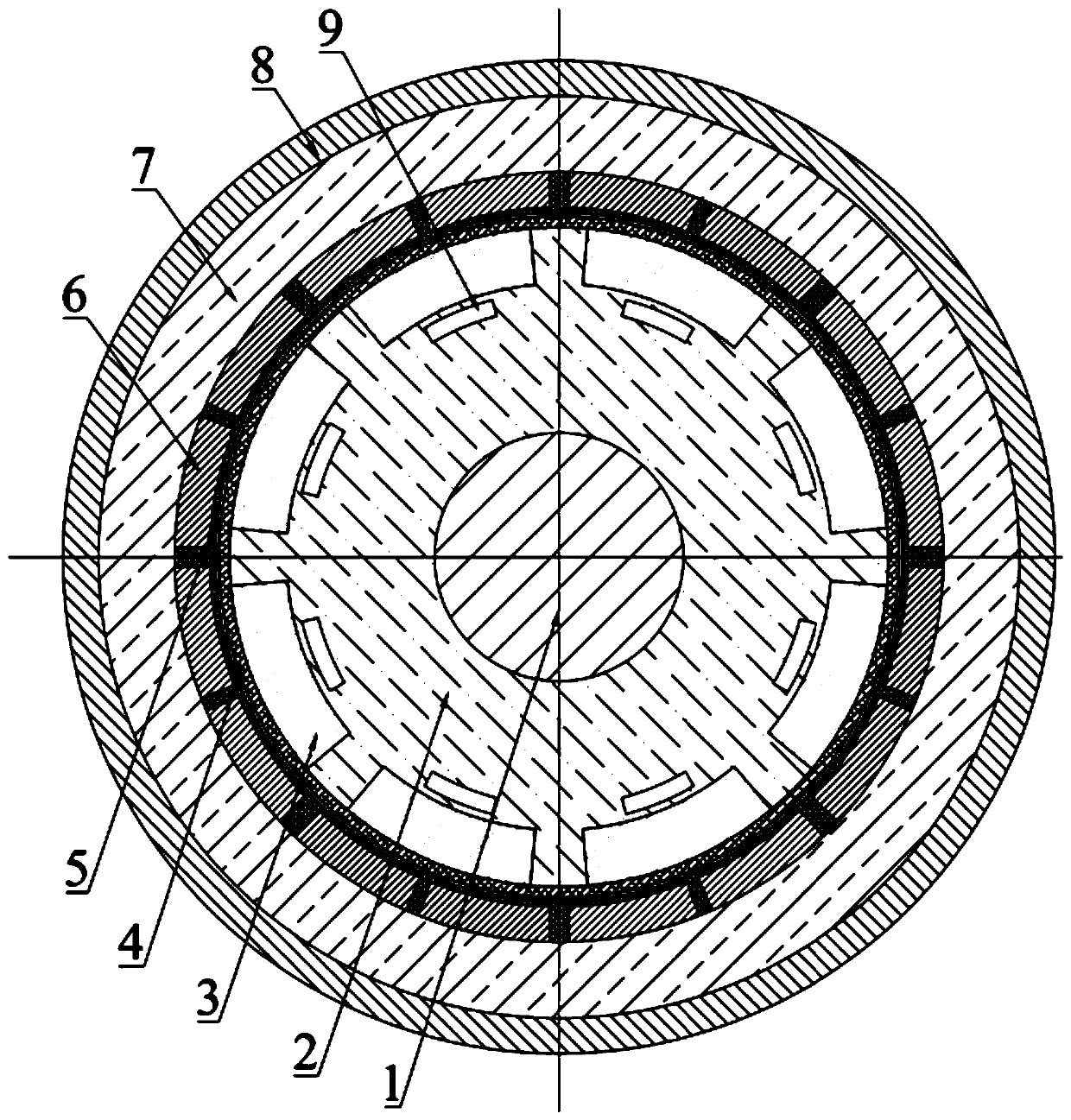

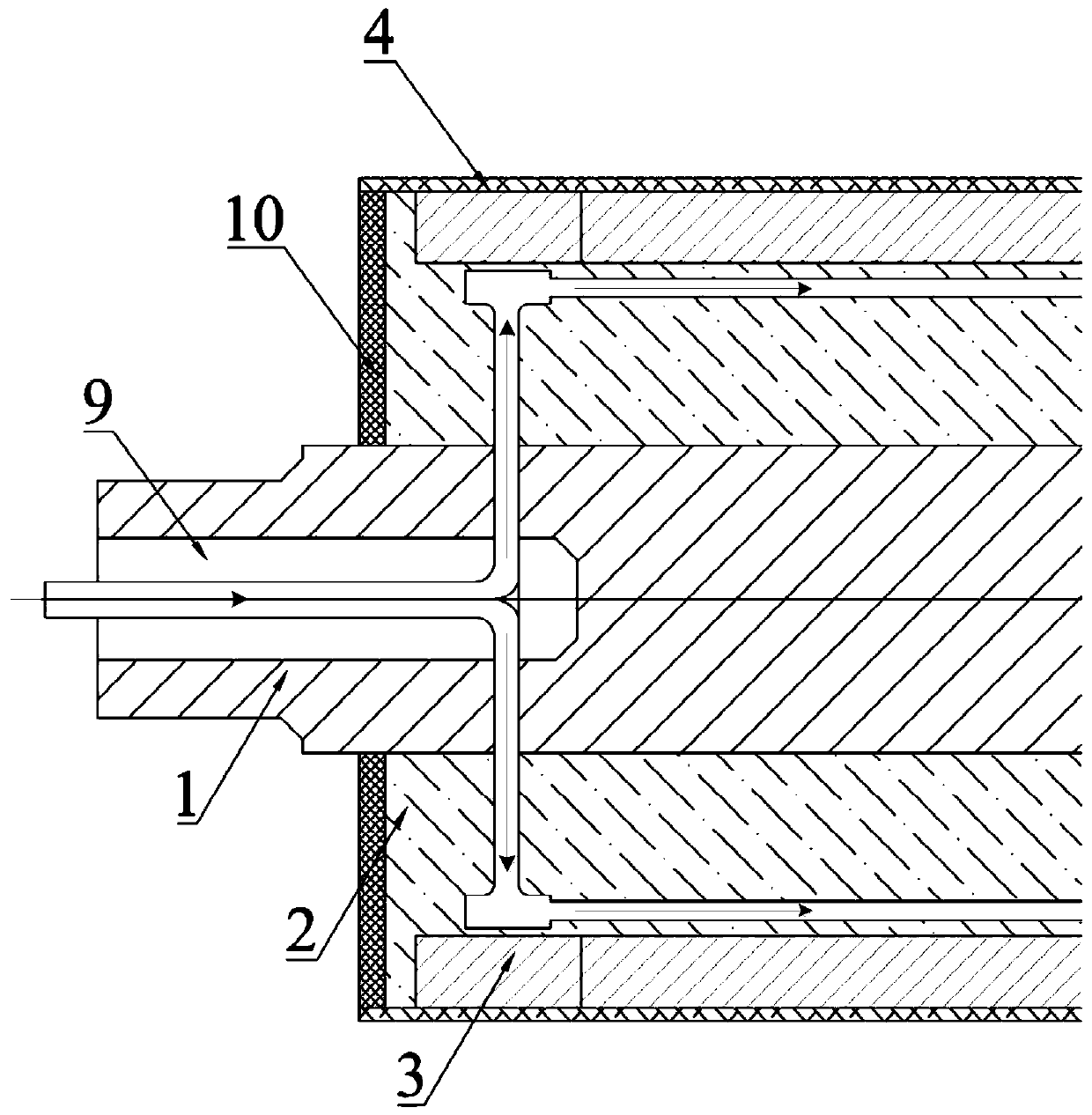

[0026] Specific implementation mode one, combination Figure 1 to Figure 4 As shown, the present invention provides an inner-rotor-cooled pulse generator, including an inner-rotor and outer-stator structure generator, with an air gap between the stator and the rotor; the rotor includes a rotating shaft 1 and a rotor yoke 2, and the rotor yoke 2 is sleeved on the rotating shaft 1; the outer surface of the rotor yoke 2 is evenly provided with a plurality of field windings 3 along the circumferential direction;

[0027] The pulse generator also includes a cooling structure 9,

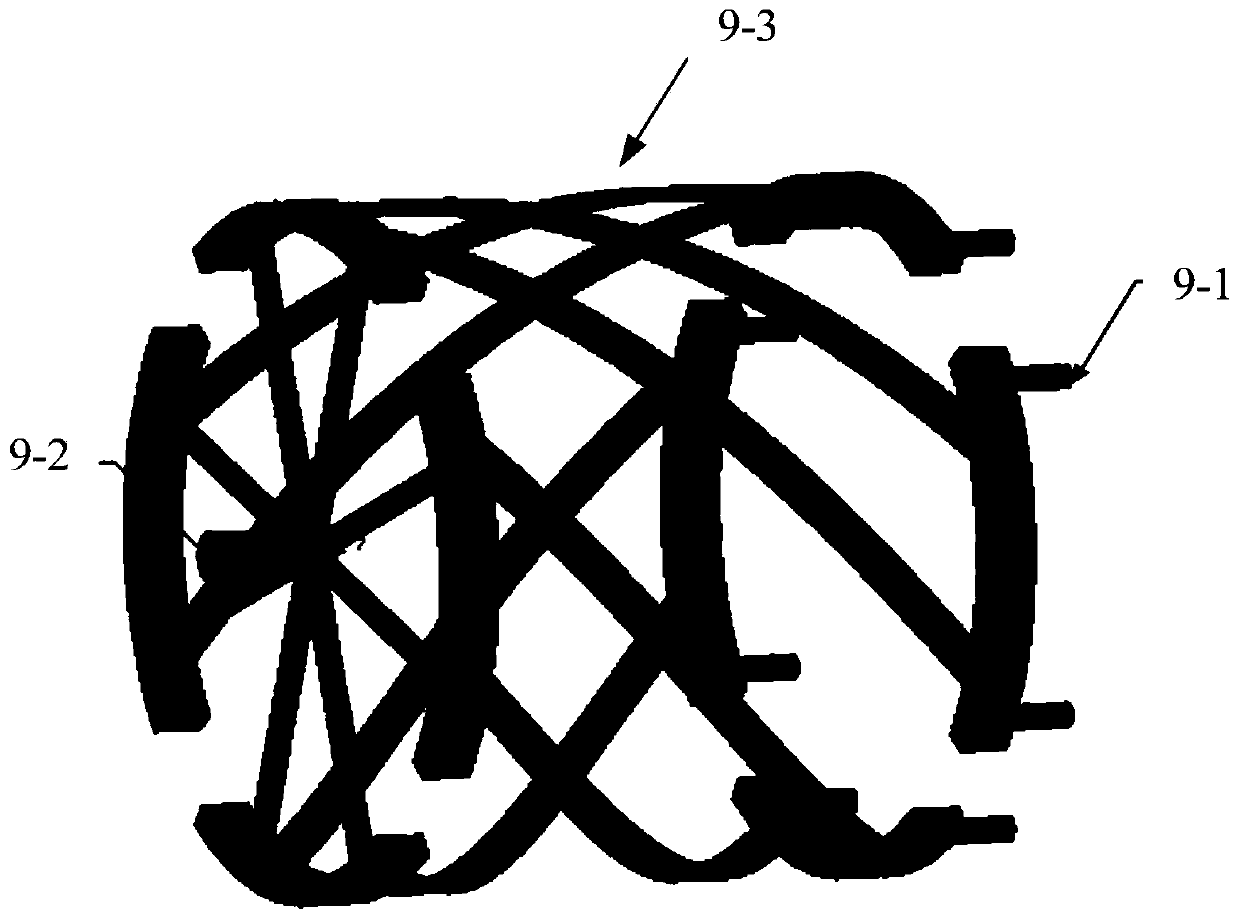

[0028] The cooling structure 9 includes a cooling water outlet section 9-1, a cooling inlet section 9-2, and an internal cooling main body 9-3. The internal cooling main body 9-3 is arranged inside the rotor yoke 2 and close to the field winding 3 in the radial direction. The position of the cooling inlet section 9-2 is introduced from the cavity provided at the end of the shaft 1, and communicates with the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com