Biaxial adjusting device for welding

An adjustment device, biaxial technology, used in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problem that the adjustment direction, angle and height cannot be accurately controlled, the direction and angle change less, welding Large welding seam error, etc., to achieve the effect of welding seam position correction, accurate positioning and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific examples are given below to further describe the technical solution of the present invention in a clear, complete and detailed manner. This embodiment is the best embodiment on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

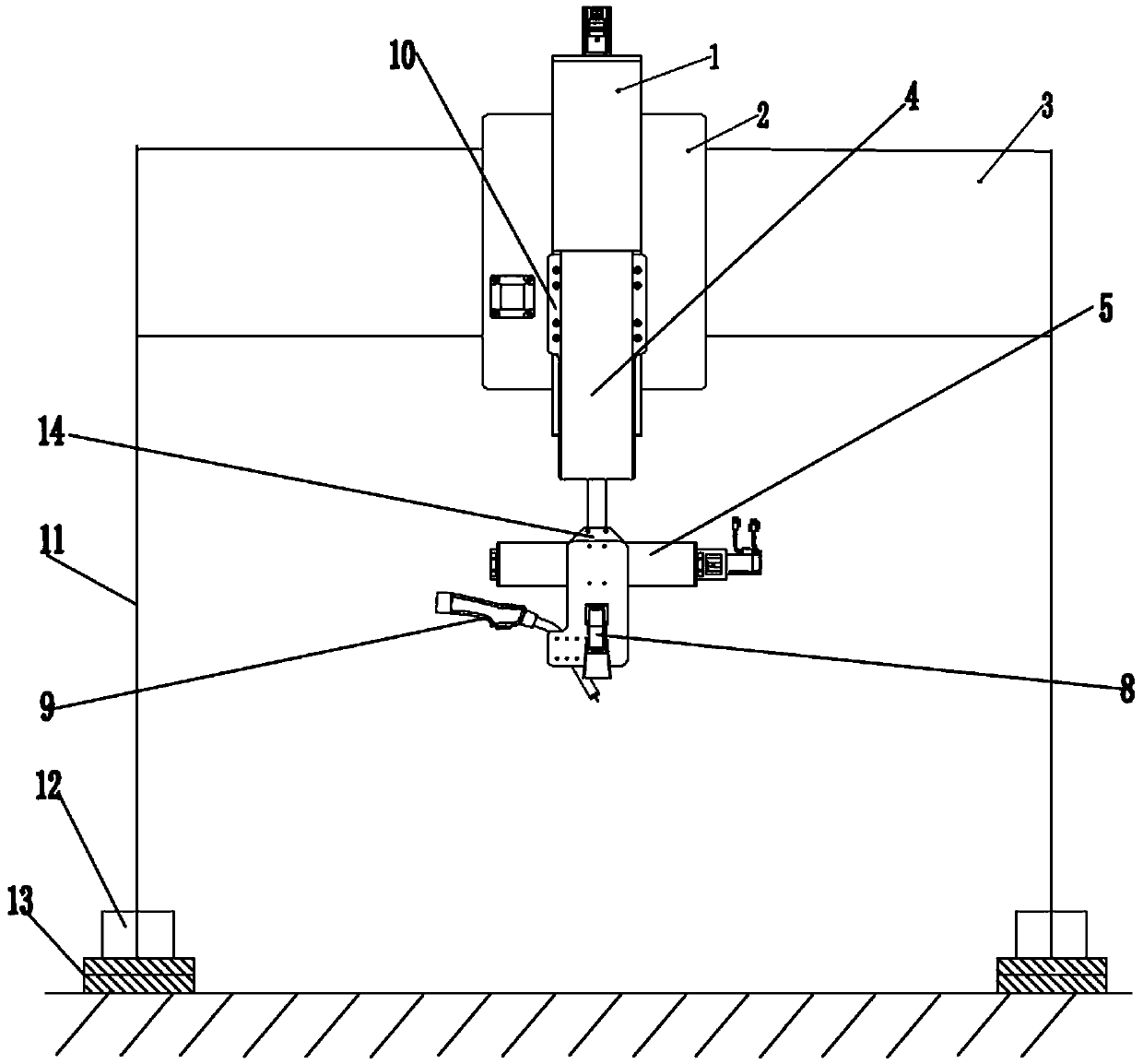

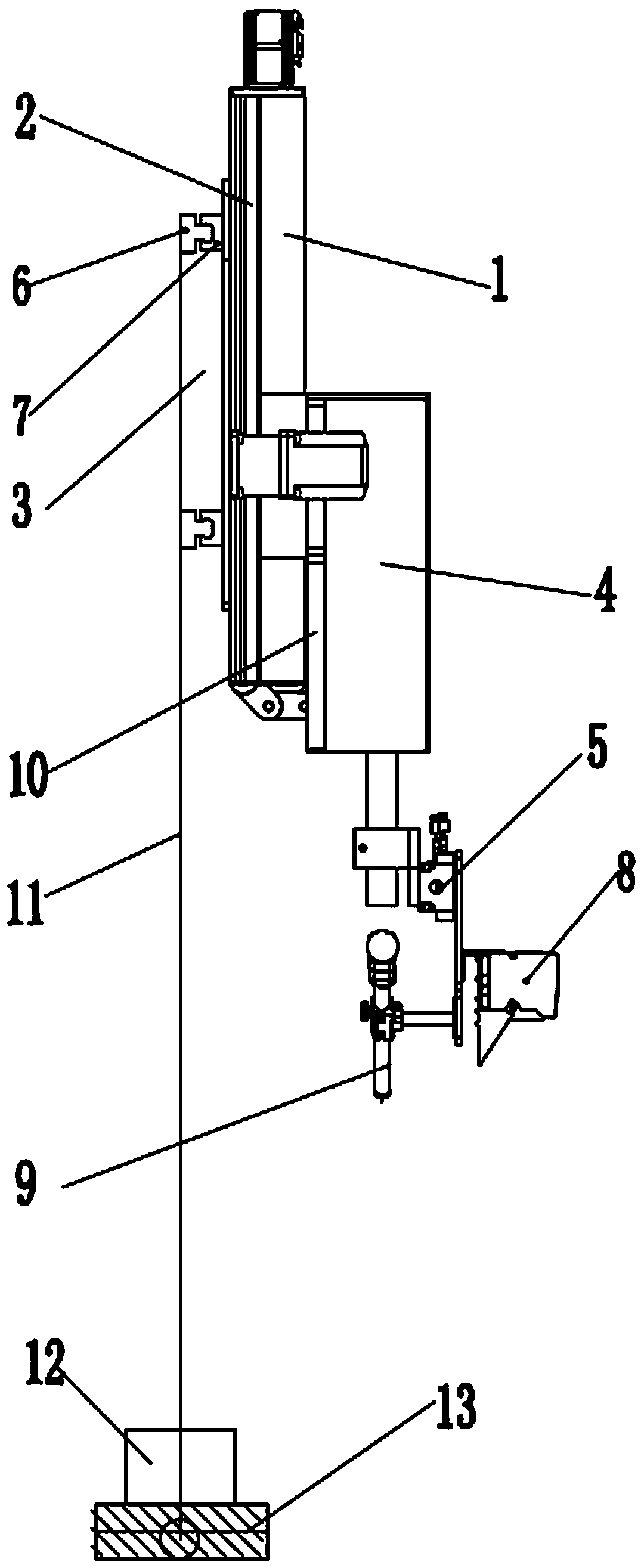

[0036] A biaxial adjustment device for welding, including a Z-direction adjustment mechanism 1, an X-direction travel mechanism 2, a Y-direction travel gantry beam 3, an R-axis rotation mechanism 4, an XY two-way adjustment mechanism 5, a guide rail 6, and a slider 7 , welding seam identification controller 8, welding torch 9, Z-axis sliding connecting plate 10, Y-direction traveling gantry column 11 and R-axis connecting plate 14;

[0037]The X-direction traveling mechanism 2 is slidably connected to the Y-direction traveling gantry beam 3 through the matching guide rail 6 and the slider 7, and the two ends of the Y-direction tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com